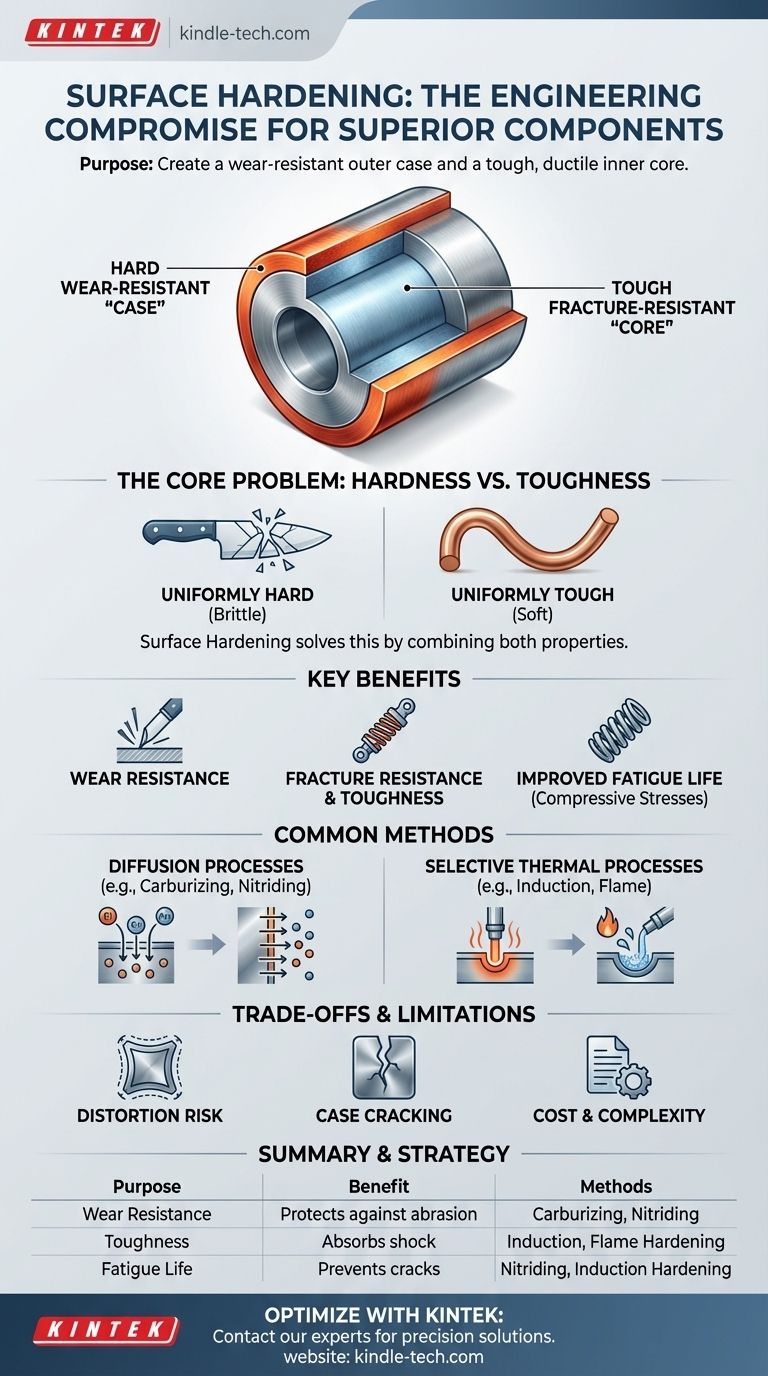

The primary purpose of surface hardening is to create a component with two distinct, desirable properties: a hard, wear-resistant outer layer and a tough, ductile inner core. This process selectively hardens only the surface of a metal part, leaving its interior—the core—in a softer, more resilient state. This dual-property structure allows a component to withstand surface abrasion and wear while still being able to absorb shock and resist fracture under load.

Surface hardening solves a fundamental engineering compromise. Instead of choosing between a hard, brittle material (which resists wear but shatters) and a soft, tough one (which resists impact but wears out), it allows you to create a single component that combines a wear-resistant "case" with a fracture-resistant "core."

The Core Engineering Problem: Hardness vs. Toughness

To grasp the value of surface hardening, you must first understand the inherent conflict between two critical material properties: hardness and toughness.

The Limits of a Uniformly Hard Part

Hardness is the ability of a material to resist surface indentation, scratching, and abrasion.

A fully hardened part, like a ceramic knife, is excellent at resisting surface wear. However, this high hardness almost always comes with high brittleness, making the part susceptible to shattering under sudden impact.

The Limits of a Uniformly Tough Part

Toughness is the ability of a material to absorb energy and deform without fracturing.

A tough part, like a copper wire, can bend and absorb shock effectively. However, it is also soft and will wear away quickly when subjected to friction or contact with harder materials.

How Surface Hardening Creates a Superior Component

Surface hardening resolves this conflict by creating a composite structure within a single part, optimizing it for real-world operational stresses.

The Wear-Resistant "Case"

The hardened outer layer, known as the case, provides the component with its durability.

This layer is specifically designed to resist abrasion, erosion, and contact fatigue. This is critical for the service life of parts like gears, bearings, and camshafts.

The Fracture-Resistant "Core"

The untreated, softer inner core retains its original toughness and ductility.

This allows the component to withstand bending forces, absorb shock loads, and resist the propagation of cracks that might start at the surface, preventing catastrophic failure.

Improved Fatigue Life

Many surface hardening methods, such as nitriding and induction hardening, introduce compressive residual stresses at the surface.

This compressive stress acts as a barrier, counteracting the tensile stresses that cause fatigue cracks to form. This can dramatically increase the fatigue life of a component.

Common Methods of Surface Hardening

While there are many specific processes, they generally fall into two main categories that achieve the hard case and tough core.

Diffusion Processes

These methods involve enriching the surface of a metal (typically steel) with elements that promote hardness.

Carburizing diffuses carbon into the surface, while nitriding uses nitrogen. When the part is subsequently heat-treated, this enriched layer becomes exceptionally hard.

Selective Thermal Processes

These methods use rapid, localized heating of the surface followed by a rapid cooling (quenching).

Induction hardening and flame hardening are common examples. The rapid thermal cycle transforms the surface's crystal structure into a hard phase (martensite), while the core remains too cool to be affected.

Understanding the Trade-offs and Limitations

While powerful, surface hardening is not a universal solution and introduces its own set of technical considerations.

Risk of Distortion

The intense heating and cooling cycles can cause the part to warp or change dimensions.

This often necessitates secondary finishing operations, such as grinding, to restore the required geometric tolerances, adding cost and time.

Potential for Case Cracking

An improperly controlled process can result in a case that is too brittle or has high internal stress.

This can lead to micro-cracks, especially at sharp corners or stress concentrations, which can compromise the part's integrity.

Cost and Complexity

Surface hardening is an additional manufacturing step. It requires specialized equipment and precise process control, which adds to the overall cost and complexity of producing a finished part.

Making the Right Choice for Your Goal

Selecting a surface hardening strategy depends entirely on the component's intended application, material, and performance requirements.

- If your primary focus is maximum wear and fatigue resistance: Diffusion methods like carburizing or nitriding create a deep, well-integrated case ideal for high-load components like transmission gears.

- If your primary focus is hardening a specific, localized area: Thermal methods like induction hardening offer exceptional speed and control for treating precise zones on parts like axle shafts.

- If your primary focus is minimizing part distortion: Low-temperature processes like gas nitriding are often chosen for complex or thin-walled components where maintaining dimensional stability is critical.

By creating this engineered composite structure, surface hardening enables the design of components that are not just durable, but fundamentally more reliable.

Summary Table:

| Purpose | Key Benefit | Common Methods |

|---|---|---|

| Wear Resistance | Hard outer layer protects against abrasion | Carburizing, Nitriding |

| Toughness | Soft inner core absorbs shock and resists fracture | Induction Hardening, Flame Hardening |

| Fatigue Life Improvement | Compressive stresses prevent crack formation | Nitriding, Induction Hardening |

Optimize your components with precision surface hardening solutions from KINTEK.

Whether you're developing high-load gears, durable bearings, or complex thin-walled parts, KINTEK's expertise in lab equipment and consumables can help you select and implement the ideal surface hardening process for your specific needs. Our solutions ensure your components achieve the perfect balance of surface hardness and core toughness for maximum reliability and service life.

Contact our experts today to discuss how we can enhance your laboratory's capabilities and improve your component performance!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- What is vacuum brazed? The Ultimate Guide to High-Purity Metal Joining

- What is a braze repair process? A Low-Heat Solution for Strong, Seamless Metal Joining

- What is the basic of brazing? A Guide to Strong, Low-Heat Metal Joining

- Which element made stainless steel difficult to brazed? It's Chromium's Oxide Layer