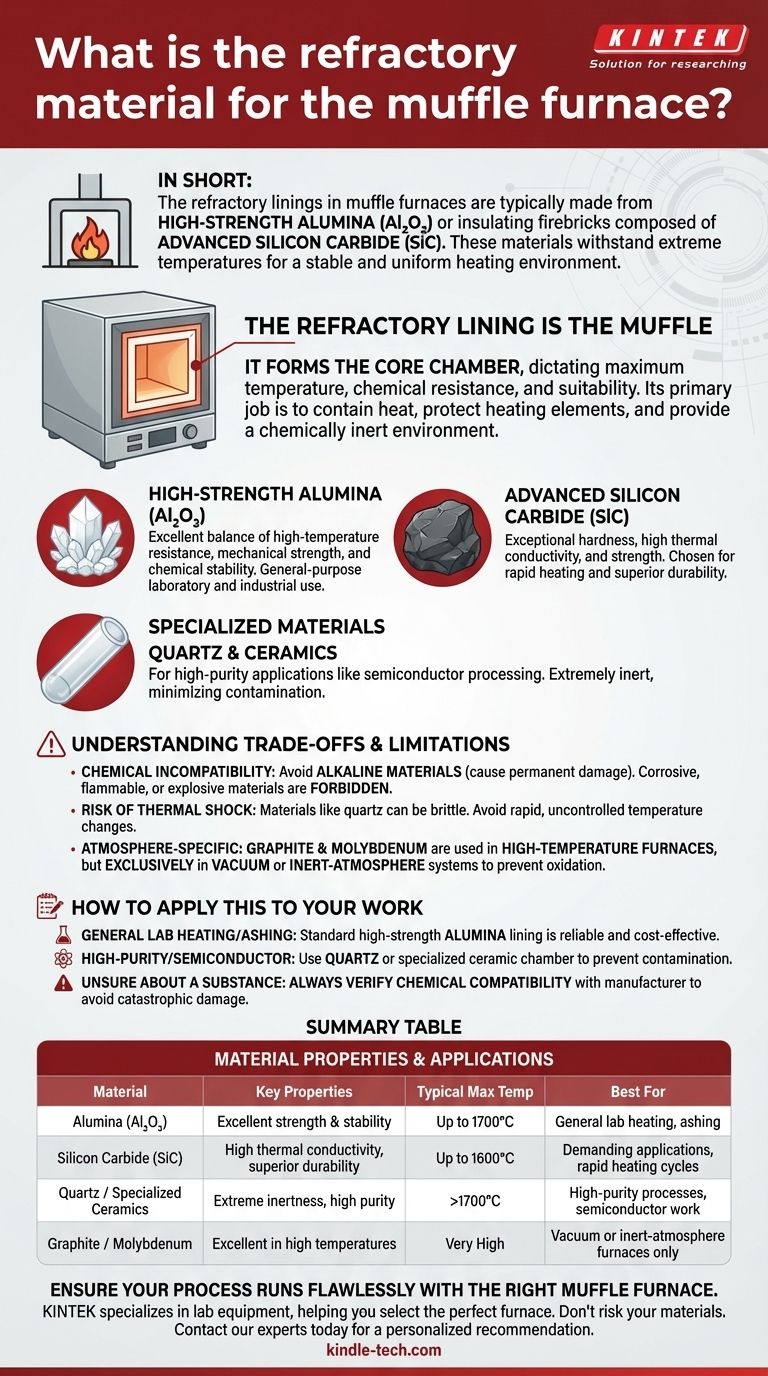

In short, the refractory linings in muffle furnaces are typically made from high-strength alumina (Al₂O₃) or insulating firebricks composed of advanced silicon carbide (SiC). These materials are chosen for their ability to withstand extreme temperatures while ensuring a stable and uniform heating environment.

The refractory material is not just insulation; it forms the core "muffle" or chamber. This material choice directly dictates the furnace's maximum temperature, chemical resistance, and suitability for specific applications.

The Role of Refractory Materials

What "Muffle" Means

A muffle furnace is defined by its insulated inner chamber, which separates the material being heated from the heating elements.

The refractory lining is the muffle. Its primary job is to contain the heat, protect the heating elements, and provide a chemically inert environment for the process.

The Goal: A Uniform and Stable Environment

The quality of the refractory material is what allows the furnace to maintain accurate and uniform process conditions.

A well-designed lining prevents heat from escaping, enabling precise temperature control and even distribution of thermal energy.

Common Refractory Materials Explained

High-Strength Alumina (Al₂O₃)

Alumina is a widely used and versatile ceramic. It serves as the workhorse material for many general-purpose laboratory and industrial muffle furnaces.

It offers an excellent balance of high-temperature resistance, mechanical strength, and chemical stability for most common applications.

Advanced Silicon Carbide (SiC)

Silicon carbide is another advanced ceramic used for refractory linings. It is known for its exceptional hardness, high thermal conductivity, and strength at elevated temperatures.

Furnaces with SiC linings are often chosen for more demanding applications that require rapid heating or superior durability.

Specialized Materials: Quartz and Ceramics

In high-purity applications, such as semiconductor processing, the inner chambers (or retorts) may be made from quartz or other specialized ceramics.

These materials offer very high maximum temperatures and are extremely inert, which minimizes contamination of the samples.

Understanding the Trade-offs and Limitations

Chemical Incompatibility

The refractory lining is not impervious to all substances. It is critical to avoid heating materials that will react with and degrade the chamber.

Alkaline materials should never be used, as they can melt or scorch the slag inside the furnace, causing permanent damage. Strongly corrosive, flammable, or explosive materials are also forbidden.

Risk of Thermal Shock

While materials like quartz can handle extremely high temperatures, they can be brittle and susceptible to thermal shock.

Rapid, uncontrolled changes in temperature can cause the lining to crack or fail, especially in materials not designed for such cycles.

Atmosphere-Specific Materials

Some refractory materials, such as graphite and molybdenum, are common in high-temperature furnaces, but almost exclusively in vacuum or inert-atmosphere systems.

These materials would quickly oxidize and burn away if used in a standard muffle furnace that operates in an air atmosphere.

How to Apply This to Your Work

The material of your muffle furnace's chamber is a critical specification, not a minor detail.

- If your primary focus is general laboratory heating or ashing: A furnace with a standard high-strength alumina lining is the most reliable and cost-effective choice.

- If your application involves high-purity materials or semiconductor work: You must use a furnace with a quartz or specialized ceramic chamber to prevent process contamination.

- If you are unsure about a substance: Always verify chemical compatibility with the furnace manufacturer before heating to avoid catastrophic damage to the refractory lining.

Choosing the right furnace—and using it correctly—starts with understanding the capabilities and limits of its core refractory materials.

Summary Table:

| Material | Key Properties | Typical Max Temperature | Best For |

|---|---|---|---|

| High-Strength Alumina (Al₂O₃) | Excellent balance of strength & stability | Up to 1700°C | General lab heating, ashing, most common applications |

| Advanced Silicon Carbide (SiC) | High thermal conductivity, superior durability | Up to 1600°C | Demanding applications, rapid heating cycles |

| Quartz / Specialized Ceramics | Extreme inertness, high purity | >1700°C | High-purity processes, semiconductor work |

| Graphite / Molybdenum | Excellent in high temperatures | Very High | Vacuum or inert-atmosphere furnaces only |

Ensure Your Process Runs Flawlessly with the Right Muffle Furnace

Choosing the correct refractory material is critical for the success, safety, and longevity of your thermal processes. The wrong choice can lead to contamination, furnace damage, or failed experiments.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select the perfect muffle furnace with the right refractory lining for your specific application—whether it's general ashing, high-temperature sintering, or high-purity material processing.

We provide reliable equipment and the technical support to ensure you get accurate, repeatable results every time.

Don't risk your materials or equipment. Contact our experts today for a personalized recommendation and enhance your lab's capabilities with KINTEK.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the function of an annealing furnace for LiNbO3 sol-gel coating? Optimize NCM Cathode Performance

- How do you determine the ash content of a plant sample? A Step-by-Step Guide to Mineral Analysis

- What role does a high-temperature muffle furnace play in FM steel heat treatment? Expert Microstructure Engineering

- What is the function of high-temperature muffle furnaces in the laboratory study of Cr-Mo steel corrosion? (5Cr-1Mo)

- How does a laboratory muffle furnace ensure accuracy in biomass ash determination? Optimize Your Material Analysis

- What is the role of muffle furnaces in sol-gel antimicrobial coatings? Optimize Thermal Curing for Silver Nanoparticles

- What is the effect of calcination temperature on the properties of nanoparticles? Master the Trade-Off for Optimal Performance

- What are the process functions of a sintering furnace in carbon xerogel synthesis? Engineering Superior Supercapacitors