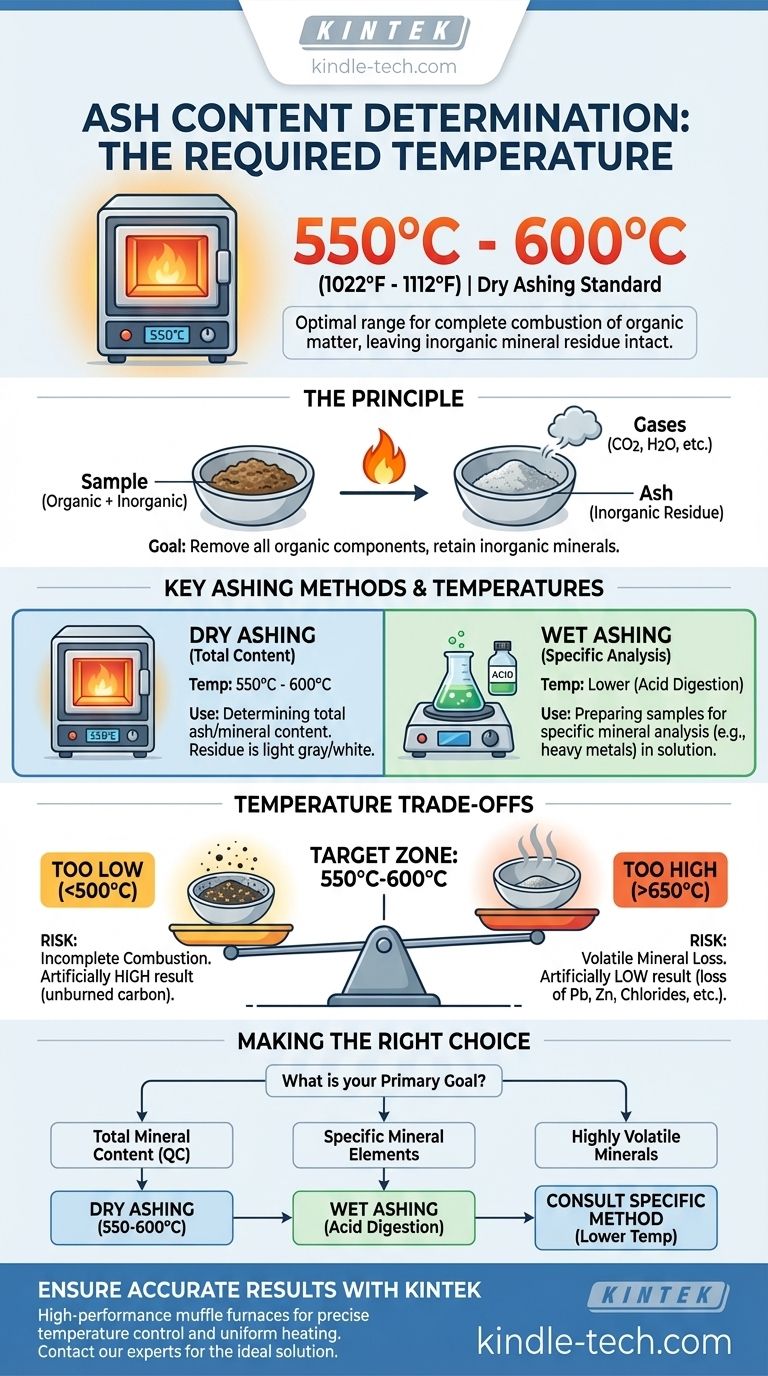

The required temperature for ash content determination typically falls within a range of 550°C to 600°C (1022°F to 1112°F). This temperature is used for the most common method, known as dry ashing, and is designed to ensure the complete combustion of all organic matter while leaving the inorganic mineral residue intact.

The specific temperature for ash analysis is not a single, universal value but a critical parameter chosen to achieve complete oxidation of the sample without losing volatile minerals. While 550-600°C is the industry standard for most applications, the ideal temperature ultimately depends on the sample's composition and the analytical goal.

The Principle of Ash Determination

What is Ash?

Ash is the inorganic, non-combustible residue that remains after a sample is completely burned. This residue consists of the oxides and salts of the mineral elements present in the original material.

The determination of ash content is a fundamental measure of the total amount of minerals within a product. It serves as a crucial quality control parameter in industries ranging from food and animal feed to polymers and pharmaceuticals.

Why Temperature is Critical

The goal of ashing is to remove all organic components (carbon, hydrogen, etc.) by converting them into gaseous products, leaving only the inorganic minerals behind.

The chosen temperature must be high enough to achieve complete combustion in a reasonable timeframe. However, it must also be low enough to prevent the loss of volatile mineral components through decomposition or vaporization, which would lead to inaccurate results.

Key Ashing Methods and Their Temperatures

Dry Ashing (The Common Standard)

This is the most widely used method for determining total ash content. The sample is placed in a high-temperature muffle furnace.

The standard procedure involves heating samples at 550°C to 600°C until a constant weight is achieved, indicating that all organic material has been burned away. The remaining residue is a light gray or white ash.

Wet Ashing (For Specific Mineral Analysis)

Wet ashing, or wet digestion, is a fundamentally different process used to prepare a sample for the analysis of specific minerals, not for determining total ash content.

This method uses strong acids (like nitric or sulfuric acid) and lower temperatures, often on a hot plate or digestion block. Its purpose is to dissolve the minerals into a solution for analysis by techniques like atomic absorption spectroscopy (AAS).

Understanding the Trade-offs

The Risk of Temperatures Too Low

If the furnace temperature is insufficient (e.g., below 500°C), the combustion of organic matter may be incomplete.

This results in an artificially high and incorrect ash value because unburned carbon residue is weighed along with the mineral ash. The remaining ash often appears dark or speckled.

The Risk of Temperatures Too High

Using excessively high temperatures (e.g., above 650°C) can cause the loss of certain volatile minerals that are critical to the final measurement.

Elements like lead, zinc, and various chlorides and carbonates can decompose or vaporize at higher temperatures, leading to an artificially low and inaccurate ash reading.

Making the Right Choice for Your Goal

Selecting the correct temperature and method is essential for accurate analysis. Your decision should be guided by your specific objective.

- If your primary focus is determining total mineral content for quality control (e.g., in food or animal feed): Dry ashing at a standard temperature between 550°C and 600°C is the correct approach.

- If your primary focus is measuring the concentration of specific mineral elements (e.g., heavy metals): Wet ashing is the appropriate preparatory method, as it preserves the target elements in a solution for further analysis.

- If your primary focus is analyzing a sample known to contain highly volatile minerals: You must consult a specific, validated method (such as from AOAC or ASTM) which may require a lower ashing temperature to prevent mineral loss.

Properly controlling the temperature is the most critical factor in achieving repeatable and reliable ash content results.

Summary Table:

| Method | Typical Temperature Range | Primary Use |

|---|---|---|

| Dry Ashing | 550°C - 600°C | Determining total ash/mineral content |

| Wet Ashing | Lower (acid digestion) | Preparing samples for specific mineral analysis |

Ensure accurate and repeatable ash content results with the right equipment from KINTEK.

Choosing the correct muffle furnace and ashing protocol is critical for reliable quality control in food, feed, polymer, and pharmaceutical analysis. KINTEK specializes in high-performance lab furnaces and consumables designed to deliver precise temperature control and uniform heating for your specific application.

Let our experts help you select the ideal solution for your lab's needs.

Contact our team today to discuss your requirements and get a personalized recommendation!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What can I use instead of a water bath in biology? Discover Cleaner, More Precise Alternatives

- How can we reduce plastic waste using technology? Leverage AI, Chemical Recycling & Bioplastics

- What is the role of the constant flow and constant pressure pump in core flooding? Master Deep Granite Stimulation

- What is the difference between PPF and coating? Armor vs. Slick Shell for Your Car

- What are the advantages of magnetron? Achieve High-Rate, Low-Damage Thin Film Deposition

- What is the 20 40 60 rule in Rotavap? A Guide to Efficient and Safe Solvent Evaporation

- What are some additional useful features in ultra-low freezers? Ensure Sample Integrity with Advanced Risk Mitigation

- What is the life cycle assessment of pyrolysis? A Guide to Its True Environmental Impact