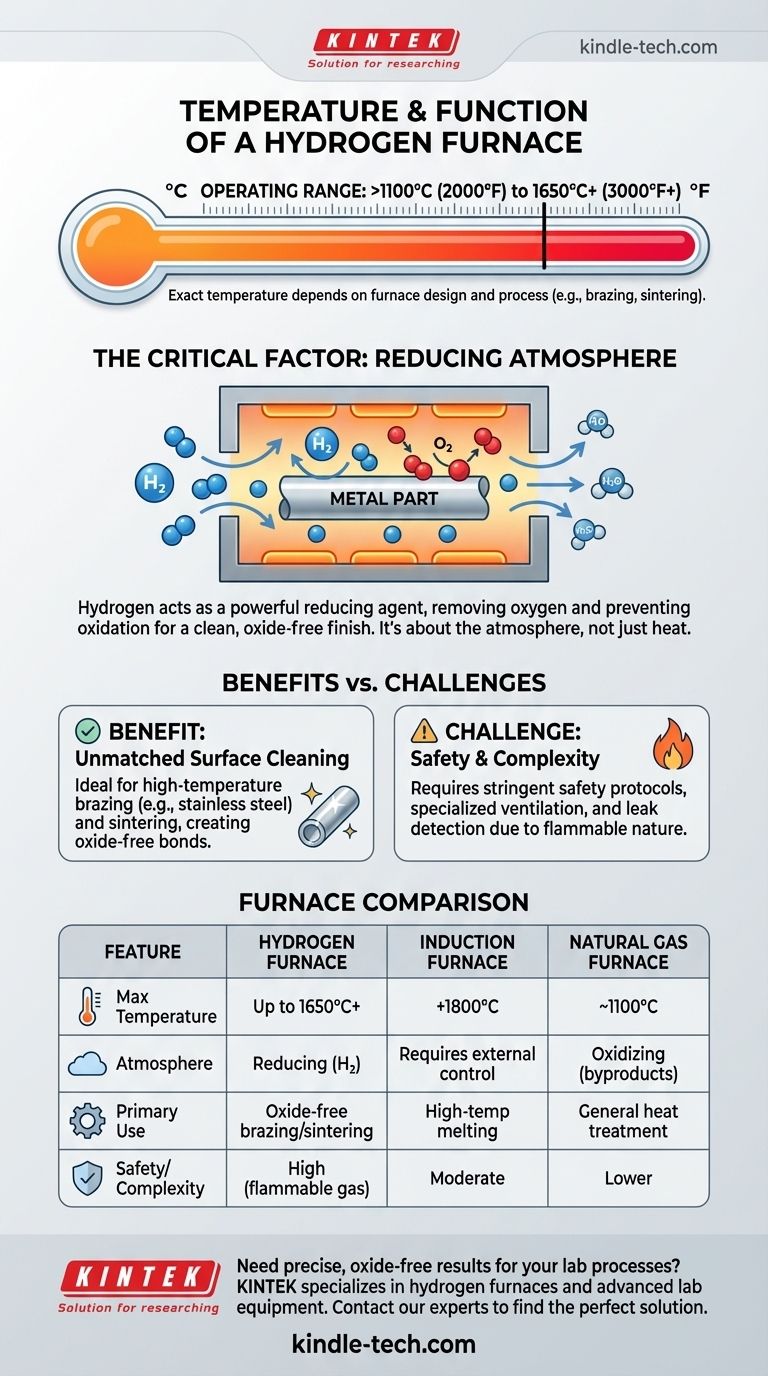

In short, a hydrogen furnace can operate at extremely high temperatures, often exceeding 1100°C (2000°F) and capable of reaching up to 1650°C (3000°F) or more for specialized applications. The exact temperature depends entirely on the furnace's design and its intended industrial process, such as brazing or sintering.

The critical factor for a hydrogen furnace is not just the high temperature it can achieve, but its ability to create a highly reducing atmosphere. This prevents oxidation and cleans the surface of metal parts during processing, which is its primary advantage over other furnace types.

What Defines a Hydrogen Furnace?

It's About the Atmosphere, Not Just Heat

The defining characteristic of a hydrogen furnace is its use of hydrogen gas as the process atmosphere. While the furnace generates heat (often via electric resistance elements), the hydrogen environment is what enables specific metallurgical processes.

This controlled atmosphere is essential for working with materials that are highly sensitive to the presence of oxygen, especially at elevated temperatures.

Preventing Oxidation at High Temperatures

As metals get hotter, they react more readily with oxygen, forming oxides on their surfaces. These oxide layers can prevent proper bonding in processes like brazing or create impurities in sintered parts.

Hydrogen acts as a powerful reducing agent. It actively reacts with and removes oxygen from the furnace chamber and from the surface of the parts themselves, resulting in a clean, bright, oxide-free finish.

How Hydrogen Furnaces Compare to Other Types

Comparison with Induction Furnaces

Induction furnaces can reach even higher temperatures, potentially exceeding 1800°C. They work by inducing an electric current directly within the metal part itself, causing it to heat rapidly.

However, an induction coil alone does not control the atmosphere. To achieve an oxide-free result, an induction process must be performed inside a vacuum chamber or a chamber filled with an inert or reducing gas, like hydrogen. A hydrogen furnace integrates the heating and atmosphere control into one system.

Comparison with Natural Gas Furnaces

A natural gas furnace, which can reach temperatures around 1100°C (2000°F), is excellent for general-purpose heating. However, the combustion of natural gas produces water vapor (H₂O) and carbon dioxide (CO₂).

These byproducts are oxidizing, making this type of furnace unsuitable for processes where surface purity is critical. A hydrogen furnace provides a much cleaner and more controlled environment.

Understanding the Trade-offs

The Benefit: Unmatched Surface Cleaning

The primary reason to choose a hydrogen furnace is for its superior cleaning and "reducing" capabilities. It is the go-to solution for high-temperature brazing of materials like stainless steel or for sintering metal powders that must be free of internal oxides.

The Challenge: Safety and Complexity

Hydrogen is highly flammable and explosive when mixed with air. Operating a hydrogen furnace requires stringent safety protocols, specialized ventilation, leak detection systems, and well-trained personnel.

This complexity and the associated safety requirements make hydrogen furnaces more expensive to install and operate compared to standard atmosphere or vacuum furnaces.

Making the Right Choice for Your Process

Choosing the correct furnace technology depends entirely on your material and desired outcome.

- If your primary focus is oxide-free bonding or sintering: A hydrogen furnace is the ideal choice due to its active reducing atmosphere.

- If your primary focus is reaching the absolute highest temperatures for melting: An induction furnace is often the most effective and efficient tool.

- If your primary focus is general heat treatment where minor oxidation is acceptable: A natural gas or standard electric atmosphere furnace offers a simpler, more cost-effective solution.

Ultimately, the right furnace is the one whose atmosphere and temperature profile best serves the needs of your material.

Summary Table:

| Feature | Hydrogen Furnace | Induction Furnace | Natural Gas Furnace |

|---|---|---|---|

| Max Temperature | Up to 1650°C+ | 1800°C+ | ~1100°C |

| Atmosphere | Reducing (H₂) | Requires external control | Oxidizing (combustion byproducts) |

| Primary Use | Oxide-free brazing/sintering | High-temp melting | General heat treatment |

| Safety/Complexity | High (flammable gas) | Moderate | Lower |

Need precise, oxide-free results for your lab processes? KINTEK specializes in hydrogen furnaces and other advanced lab equipment designed for high-temperature applications like brazing and sintering. Our solutions ensure superior surface quality and process control for your laboratory needs. Contact our experts today to find the perfect furnace for your materials and goals!

Visual Guide

Related Products

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What types of atmospheres are used during sintering? Choose the Right Gas for Your Material

- What inert gas is used in a heat treat oven? Choosing Nitrogen vs. Argon for Your Process

- What is a controlled atmosphere heat treatment furnace? Achieve Superior Metallurgical Results

- What is the meaning of reducing atmosphere? Control Oxidation for Superior Material Processing

- What is the brazing process? A Guide to Strong, Versatile, and Aesthetic Joining

- What is the function of a tube atmosphere furnace in FeOOH@C to Fe@C conversion? Mastering Hydrogen Thermal Annealing

- What are the different types of sintering atmospheres? Choose the Right One for Your Material

- How an Atmosphere Tube Furnace Prepares Oxygen-Deficient RPPO via Reduction: Achieve Superior Ionic Conductivity