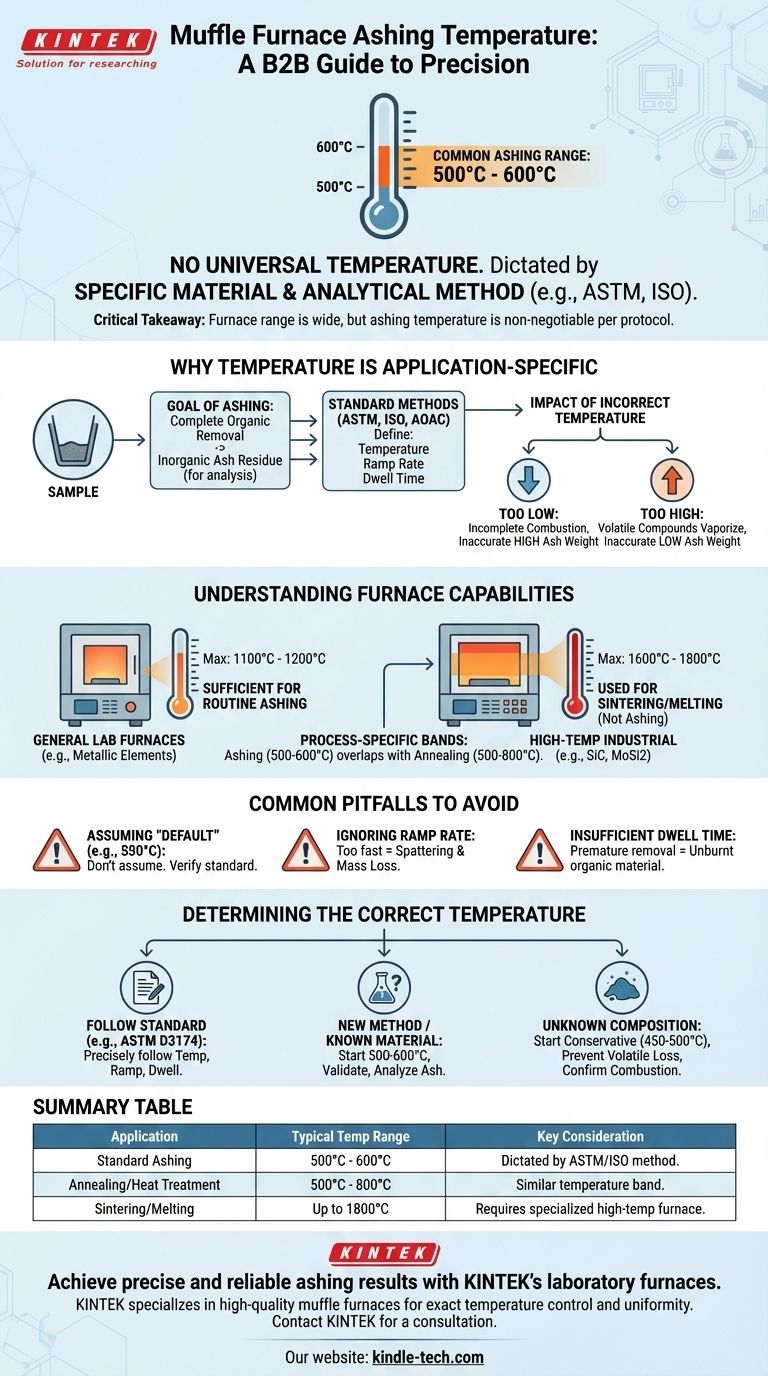

While there is no single universal temperature, muffle furnace ashing is most commonly performed in a range between 500°C and 600°C. The precise temperature is not determined by the furnace's capability but is dictated entirely by the specific material being analyzed and the standard analytical method (e.g., ASTM, ISO) being followed.

The critical takeaway is that a muffle furnace is a tool with a wide operational range, but the correct temperature for ashing is a non-negotiable parameter set by your specific scientific protocol.

Why Ashing Temperature is Application-Specific

To determine the correct temperature, you must first understand the goal of the process and the factors that influence the outcome. The furnace provides the heat, but the methodology provides the instructions.

The Goal of Ashing

Ashing is a process of thermal decomposition designed to completely remove all organic matter from a sample. This leaves behind only the inorganic, non-combustible residue—the ash—which can then be analyzed for its mineral content.

The Central Role of Standard Methods

For most materials, ashing procedures are rigorously defined by standard-setting organizations like ASTM, ISO, or AOAC. These protocols specify the exact temperature, the rate of temperature increase (ramp rate), and the duration the sample is held at the peak temperature (dwell time).

The Impact of Incorrect Temperature

Selecting the wrong temperature directly invalidates results. Setting it too low results in incomplete combustion and an inaccurately high ash weight. Setting it too high can cause certain volatile inorganic compounds (like chlorides or some metal oxides) to vaporize, leading to an inaccurately low ash weight.

Understanding Muffle Furnace Capabilities

While ashing occurs at relatively moderate temperatures, muffle furnaces are built for a wide variety of thermal applications. Their maximum temperature is determined by their heating elements.

General Purpose Laboratory Furnaces

Most laboratory furnaces used for routine ashing have metallic wire heating elements. These furnaces typically operate effectively up to a maximum temperature of 1100°C to 1200°C, which is more than sufficient for any standard ashing protocol.

High-Temperature Industrial Furnaces

Specialized furnaces use advanced heating elements to reach much higher temperatures. Models with silicon carbide elements can reach 1600°C, while those with molybdenum disilicide can achieve 1800°C.

Process-Specific Temperature Bands

These high temperatures are not for ashing. They are used for processes like sintering ceramics or melting metals. For context, annealing and other heat treatments typically occur between 500°C and 800°C—the same range where ashing resides.

Common Pitfalls to Avoid

Achieving accurate ashing results requires more than just setting the right temperature. Procedural errors can easily compromise your data.

Assuming a "Default" Temperature

Never assume a generic temperature like 550°C is correct without verification. Always consult the specific standard method for your sample type first.

Ignoring the Ramp Rate

Heating a sample too quickly can cause it to spatter, ejecting material from its crucible. This leads to a direct loss of mass and an inaccurate final measurement. The ramp rate must be slow and controlled.

Insufficient Dwell Time

A sample must be held at the target temperature long enough for combustion to complete. Removing it prematurely will leave unburnt organic material, skewing the results.

Determining the Correct Temperature for Your Sample

Your approach should be dictated by the context of your analysis. Use the following guidelines to ensure you are setting the correct parameters for your muffle furnace.

- If you are following a standard method (e.g., ASTM D3174 for coal): The protocol is your definitive guide. Follow the specified temperature, ramp rate, and dwell time precisely.

- If you are developing a new method for a known material: Begin with the common range of 500°C to 600°C and perform validation tests, analyzing the ash to ensure key minerals have not been lost.

- If you are working with a sample of unknown composition: Start with a conservative temperature (e.g., 450°C to 500°C) to prevent the loss of volatile analytes, and run tests to confirm combustion is complete.

Ultimately, successful ashing depends on methodical precision, not just the power of your equipment.

Summary Table:

| Application | Typical Temperature Range | Key Consideration |

|---|---|---|

| Standard Ashing | 500°C - 600°C | Dictated by ASTM/ISO method for the specific material. |

| Annealing / Heat Treatment | 500°C - 800°C | Similar temperature band to ashing. |

| Sintering / Melting | Up to 1800°C | Requires specialized high-temperature furnace models. |

Achieve precise and reliable ashing results with KINTEK's laboratory furnaces.

Choosing the right equipment is as critical as following the correct method. KINTEK specializes in high-quality muffle furnaces that deliver the exact temperature control and uniformity your ASTM or ISO protocols demand. Whether you're processing coal, food, or pharmaceuticals, our lab equipment ensures your ashing process is accurate and repeatable.

Let our experts help you select the perfect furnace for your laboratory's needs.

Contact KINTEK today for a consultation to discuss your application and ensure your results are never compromised by inadequate equipment.

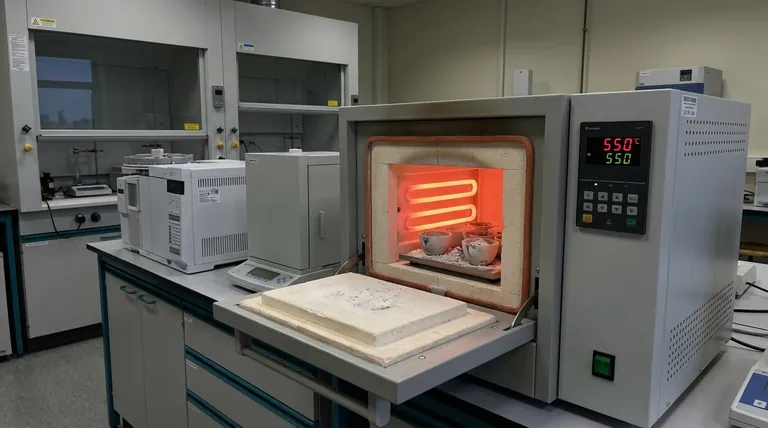

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- At what temperature does ceramic melt? A Guide to Ceramic Heat Resistance

- What is the application of a muffle furnace? Achieve Contamination-Free High-Temperature Processing

- What PPE is required for a muffle furnace? Essential Gear for High-Temperature Safety

- What is a muffle furnace used for in microbiology? Essential for Depyrogenation and Ashing

- What are the advantages and disadvantages of sintering? A Guide to High-Performance Manufacturing