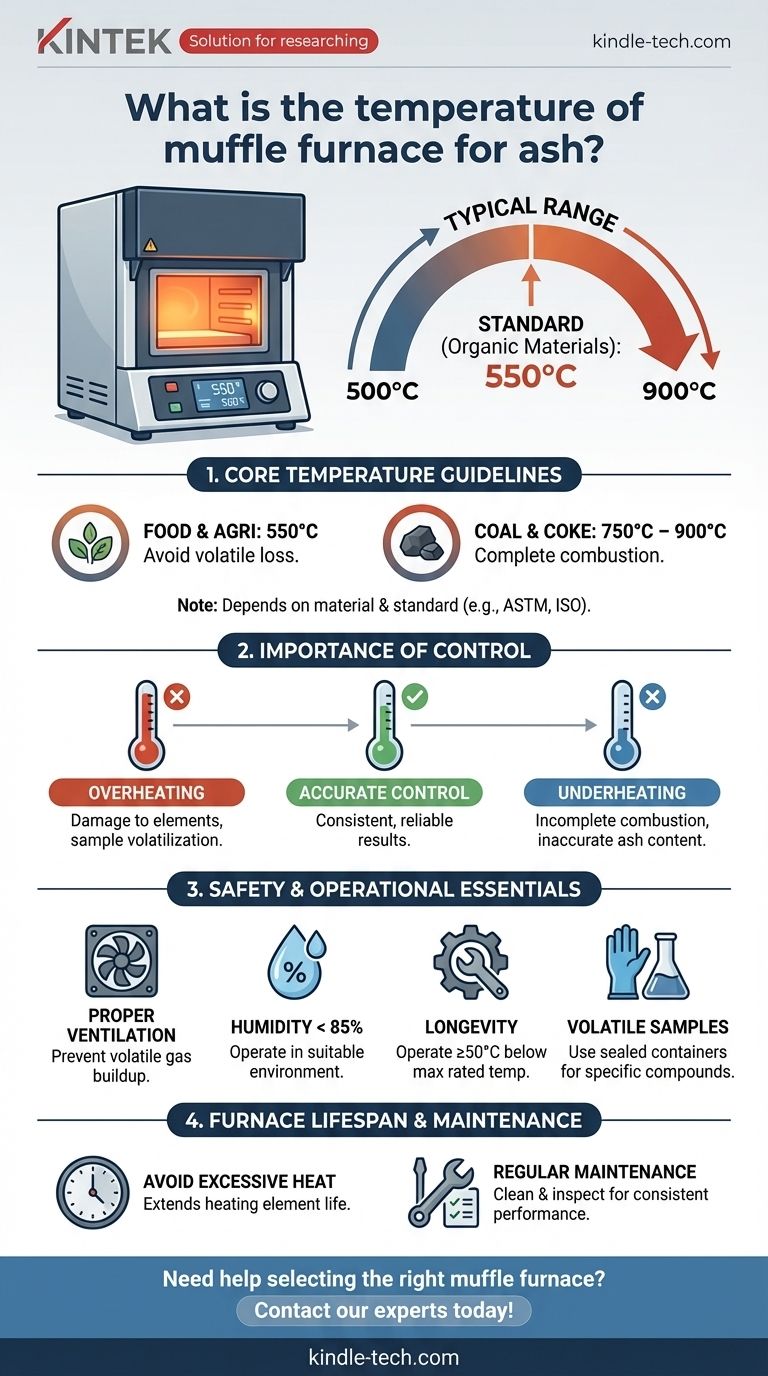

The temperature of a muffle furnace for ash determination typically ranges between 500°C and 900°C, depending on the specific material being tested and the standard method being followed. For most organic materials, a temperature of around 550°C is commonly used to ensure complete combustion and accurate ash content measurement. The furnace must be operated within its specified temperature range, ensuring proper ventilation and safety precautions to handle volatile gases and prevent damage to the heating elements. The precise temperature setting is critical to achieving reliable results while maintaining the furnace's longevity.

Key Points Explained:

-

Typical Operating Temperature Range for Ash Determination

- Muffle furnaces are commonly used for ash determination in materials such as food, coal, and other organic substances.

- The standard temperature for ash determination is 550°C, as this temperature ensures complete combustion of organic matter while leaving behind inorganic residues (ash).

- For some materials, higher temperatures (up to 900°C) may be required to achieve complete ashing, depending on the material's composition and the testing standard being followed.

-

Importance of Temperature Control

- Accurate temperature control is critical for consistent and reliable results.

- Overheating can damage the furnace's heating elements or cause the sample to volatilize, leading to inaccurate measurements.

- Underheating may result in incomplete combustion, leaving behind unburned organic material and skewing the ash content results.

-

Safety and Operational Considerations

- Muffle furnaces must be operated in environments with relative humidity not exceeding 85% and free from conductive dust, explosive gases, or corrosive gases.

- When heating materials that release volatile gases, such as metals with grease or organic compounds, sealed containers or appropriate ventilation should be used to prevent corrosion of the heating elements.

- The furnace should be operated at least 50°C below its maximum rated temperature to ensure the longevity of the heating elements.

-

Temperature Setting and Monitoring

- The furnace's control panel allows users to set the desired temperature and monitor real-time temperature, input current, voltage, and output power.

- As the furnace heats up, the real-time temperature display ensures that the system is functioning correctly and reaching the target temperature.

-

Material-Specific Temperature Requirements

- Different materials may require specific temperature settings for ash determination. For example:

- Coal and coke: Typically ashed at 750°C to 900°C to ensure complete combustion of carbonaceous material.

- Food and agricultural products: Commonly ashed at 550°C to avoid excessive loss of volatile inorganic compounds.

- Always refer to the relevant testing standard (e.g., ASTM, ISO) for precise temperature requirements.

- Different materials may require specific temperature settings for ash determination. For example:

-

Furnace Lifespan and Maintenance

- Operating the furnace at excessively high temperatures can shorten the lifespan of the heating elements.

- Regular maintenance, including cleaning and inspection of the heating elements, ensures consistent performance and extends the furnace's operational life.

-

Environmental and Ventilation Requirements

- Proper ventilation is essential to prevent the buildup of volatile gases and ensure safe operation.

- The furnace should be placed in a well-ventilated area, and any exhaust gases should be directed away from the workspace.

By following these guidelines, users can ensure accurate ash determination, maintain the furnace's performance, and adhere to safety standards. Always consult the furnace's user manual and relevant testing standards for specific temperature and operational requirements.

Summary Table:

| Key Aspect | Details |

|---|---|

| Typical Temperature Range | 500°C–900°C, depending on material and testing standards. |

| Standard Temperature | 550°C for most organic materials. |

| Material-Specific Requirements | Coal/coke: 750°C–900°C; Food/agriculture: 550°C. |

| Safety Considerations | Operate below max temperature, ensure ventilation, and avoid corrosive gases. |

| Maintenance Tips | Regular cleaning and inspection to extend furnace lifespan. |

Need help selecting the right muffle furnace for your lab? Contact our experts today!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the safety rules for all heating process in the laboratory? A Guide to Preventing Accidents

- Is a furnace endothermic or exothermic? Uncover the Science of Home Heating

- What are the applications of muffle furnace in pharmaceutical industry? Ensure Drug Purity and Quality

- What is the temperature of heat treatment? It Depends on Your Metal and Desired Properties

- What is the operating range of a muffle furnace? Unlock the Key to Your High-Temperature Tasks