In short, there is no single temperature for thermal evaporation deposition. The correct temperature is entirely dependent on the specific material being deposited, as each element or compound requires a different amount of heat to evaporate at a useful rate inside a vacuum.

The goal of thermal evaporation is not to reach a fixed temperature, but to heat a source material until it achieves a sufficient vapor pressure. The temperature required to do this varies dramatically from one material to another.

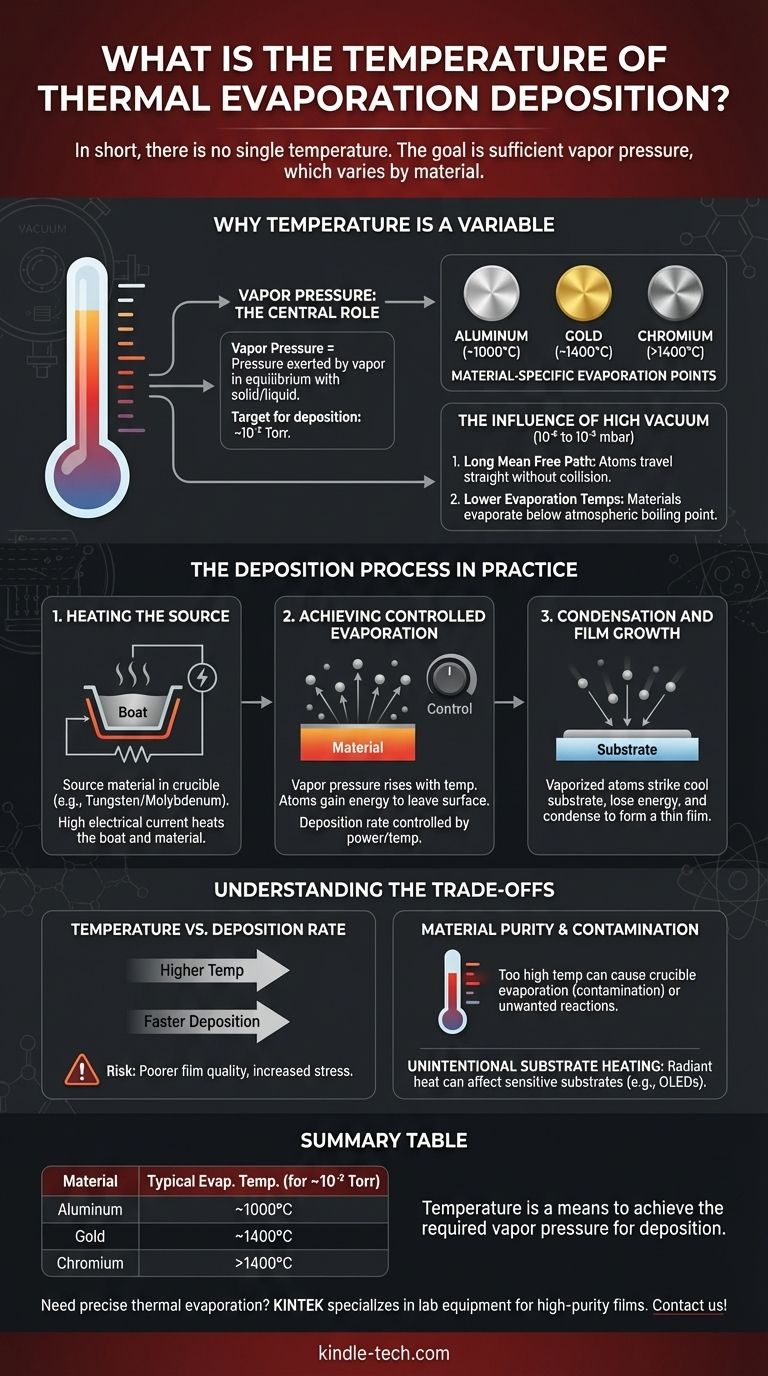

Why Temperature is a Variable, Not a Constant

Thinking about a single process temperature is a common misconception. The reality is that temperature is a means to an end, and that end is controlled evaporation.

The Central Role of Vapor Pressure

The entire process hinges on a property called vapor pressure. This is the pressure exerted by a vapor in equilibrium with its solid or liquid phase.

To deposit a film, you must heat the source material until its vapor pressure is significantly higher than the chamber's base pressure. A typical target vapor pressure for deposition is around 10⁻² Torr.

Material-Specific Evaporation Points

Every material has a unique relationship between temperature and vapor pressure.

For example, aluminum must be heated to approximately 1000°C to reach the target vapor pressure for deposition. In contrast, gold requires a much higher temperature, around 1400°C, to evaporate at a similar rate. Materials like chromium require even higher temperatures.

The Influence of High Vacuum

The process is performed in a high-vacuum chamber (typically 10⁻⁶ to 10⁻⁵ mbar) for two critical reasons.

First, the vacuum removes air molecules, which ensures a long mean free path. This allows the evaporated atoms to travel from the source to the substrate in a straight line without colliding with background gases.

Second, in a vacuum, materials can evaporate at temperatures well below their standard atmospheric boiling point.

The Deposition Process in Practice

Understanding the relationship between heat, material, and vacuum clarifies how the process works from start to finish.

Heating the Source

The source material, such as metal pellets or powder, is placed in a container called a crucible or "boat." This boat is often made of a refractory material like tungsten or molybdenum.

A very high electrical current is passed through the boat, causing it to heat up rapidly due to its electrical resistance. This heat is then transferred to the source material.

Achieving Controlled Evaporation

As the source material's temperature rises, its vapor pressure increases exponentially. Once the vapor pressure is high enough, atoms gain enough energy to leave the surface and travel outwards.

The operator controls the deposition rate by carefully adjusting the power supplied to the heating element, which in turn controls the source temperature and its resulting vapor pressure.

Condensation and Film Growth

The stream of vaporized atoms travels through the vacuum chamber and strikes the much cooler substrate (the surface being coated).

Upon hitting the cold substrate, the atoms lose their energy, condense back into a solid state, and gradually build up to form a thin, uniform film.

Understanding the Trade-offs

Simply increasing the temperature is not always the best approach. The choice of temperature involves critical trade-offs that affect the quality of the final film.

Temperature vs. Deposition Rate

A higher source temperature leads to a higher vapor pressure and therefore a faster deposition rate. While this can shorten process time, it can also lead to poorer film quality, increased stress, and a less uniform structure.

Material Purity and Contamination

If the temperature is too high, it can cause the crucible material itself to evaporate, contaminating the film. It can also cause undesirable reactions between the source material and the crucible.

Unintentional Substrate Heating

The hot evaporation source radiates a significant amount of heat. This radiant energy can heat the substrate, which is often undesirable, especially when coating sensitive materials like plastics or organic electronics (OLEDs).

How to Determine the Right Temperature for Your Project

The correct temperature setting is a function of your material, your equipment, and your desired outcome. Use published vapor pressure charts as your guide.

- If your primary focus is depositing a standard metal (e.g., Aluminum): Consult a vapor pressure chart for aluminum and find the temperature that corresponds to a vapor pressure of ~10⁻² Torr as a starting point.

- If your primary focus is achieving high film purity: Choose a temperature that provides a stable, moderate deposition rate rather than the fastest rate possible to minimize the risk of co-evaporation from the heating element.

- If your primary focus is coating a temperature-sensitive substrate: Use the lowest possible source temperature that still gives you an acceptable deposition rate and consider using heat shields or increasing the source-to-substrate distance.

Ultimately, mastering thermal evaporation comes from understanding that temperature is the tool you use to control the material's fundamental vapor pressure.

Summary Table:

| Material | Typical Evaporation Temperature (for ~10⁻² Torr) |

|---|---|

| Aluminum | ~1000°C |

| Gold | ~1400°C |

| Chromium | >1400°C |

Temperature is a means to achieve the required vapor pressure for deposition.

Need precise thermal evaporation for your specific materials? KINTEK specializes in lab equipment and consumables, providing the exact solutions for your deposition challenges. Our expertise ensures high-purity films and optimal process parameters for materials from aluminum to gold. Contact our experts today to discuss your project and achieve superior thin-film results!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Evaporation Boat for Organic Matter

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What are the drawbacks of PECVD? Understanding the Trade-offs of Low-Temperature Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the components of PECVD? A Guide to Low-Temperature Thin Film Deposition Systems

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings