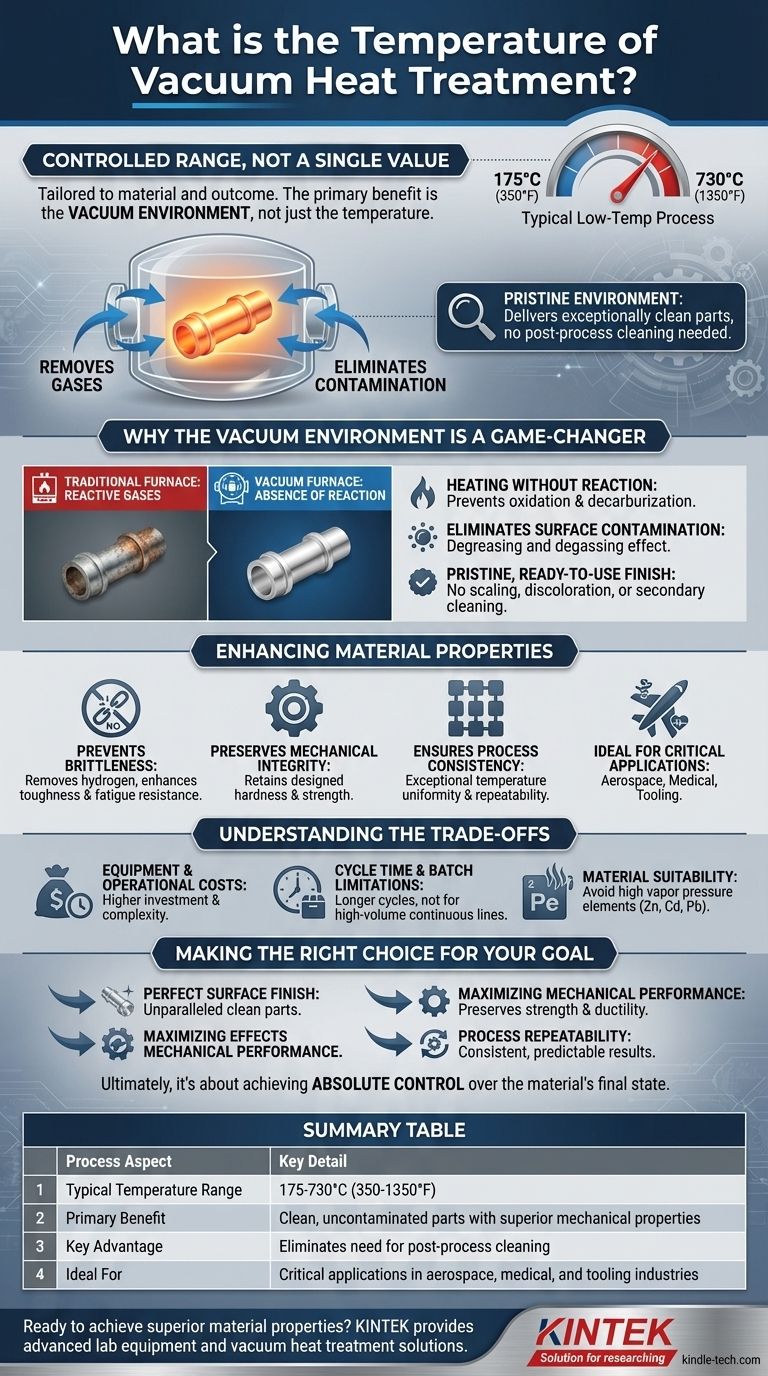

In vacuum heat treatment, temperature is not a single value but a controlled range tailored to the specific material and desired outcome. Most low-temperature vacuum processes operate between 175-730°C (350-1350°F). While specialized applications can extend this range, the key is not the temperature itself but the pristine environment in which the heating occurs.

The specific temperature is secondary to the primary benefit of the vacuum environment. By removing atmospheric gases, the process delivers exceptionally clean, uncontaminated parts with superior mechanical properties, eliminating the need for post-process cleaning.

Why the Vacuum Environment is a Game-Changer

Understanding vacuum heat treatment requires shifting focus from the temperature to the atmosphere—or lack thereof. The entire value of the process stems from heating materials in a near-total absence of reactive gases.

The Core Principle: Heating Without Reaction

In a traditional furnace, the air's oxygen and other elements react with the hot metal surface. This causes undesirable effects like oxidation (scaling) and decarburization (loss of surface carbon and hardness).

A vacuum furnace removes these reactive elements. This allows the material to be heated to the required temperature without altering its surface chemistry, preserving its integrity and finish.

Eliminating Surface Contamination

The vacuum actively cleans the workpiece. As the part heats up, the low-pressure environment helps pull contaminants like lubrication residues, oxide films, and trapped gases off and away from the surface.

This results in a degreasing and degassing effect, which is critical for preparing parts for subsequent processes like brazing or coating.

A Pristine, Ready-to-Use Finish

A major advantage is that parts emerge from the furnace with a bright, clean surface, free from scaling or discoloration.

This high-quality finish often eliminates the need for secondary cleaning operations like sandblasting or chemical baths, saving significant time and cost.

Enhancing Material Properties

The controlled vacuum environment does more than protect the surface; it actively improves the bulk properties of the material itself.

Preventing Brittleness and Weakness

Processes like hydrogen embrittlement, where hydrogen atoms infiltrate the metal and reduce its ductility, are impossible in a vacuum. By removing hydrogen, the treatment enhances the material's toughness, fatigue resistance, and overall lifespan.

Preserving Mechanical Integrity

Because the process prevents surface decarburization, the workpiece retains its designed hardness and strength. This ensures that the mechanical properties are consistent and reliable throughout the part.

Ensuring Process Consistency

Vacuum furnaces offer exceptional temperature uniformity and control. This leads to highly repeatable and invariable results from one batch to the next, which is essential for critical applications in aerospace, medical, and tooling industries.

Understanding the Trade-offs

While highly effective, vacuum heat treatment is not the universal solution. It involves specific considerations that make it ideal for some applications but less practical for others.

Equipment and Operational Costs

Vacuum furnaces represent a significant capital investment compared to standard atmospheric furnaces. The complexity of creating and maintaining a vacuum also adds to the operational cost and expertise required.

Cycle Time and Batch Limitations

Pulling a vacuum and carefully controlling the heating and cooling cycles can take longer than conventional heat-treating methods. The process is inherently batch-oriented, which may not be suitable for high-volume, continuous production lines.

Material Suitability

Certain alloys containing elements with a high vapor pressure (like zinc, cadmium, or lead) can be problematic. At high temperatures and low pressures, these elements can vaporize (outgas) from the alloy, potentially altering its composition and contaminating the furnace.

Making the Right Choice for Your Goal

Selecting the right heat treatment depends entirely on your final objective for the part.

- If your primary focus is a perfect surface finish: Vacuum heat treatment is unparalleled for producing clean, bright parts that require no post-processing.

- If your primary focus is maximizing mechanical performance: The process prevents embrittlement and decarburization, preserving the material's inherent strength, ductility, and fatigue life.

- If your primary focus is process repeatability for critical components: The highly controlled vacuum environment ensures consistent, predictable results from batch to batch.

Ultimately, vacuum heat treatment is less about a specific temperature and more about achieving absolute control over the material's final state.

Summary Table:

| Process Aspect | Key Detail |

|---|---|

| Typical Temperature Range | 175-730°C (350-1350°F) |

| Primary Benefit | Clean, uncontaminated parts with superior mechanical properties |

| Key Advantage | Eliminates need for post-process cleaning |

| Ideal For | Critical applications in aerospace, medical, and tooling industries |

Ready to achieve superior material properties and pristine finishes for your critical components?

At KINTEK, we specialize in providing advanced lab equipment, including vacuum heat treatment solutions, tailored to meet the rigorous demands of laboratories in aerospace, medical, and tooling industries. Our expertise ensures you get the precise temperature control and contamination-free environment needed for consistent, high-quality results.

Contact us today to learn how KINTEK's solutions can enhance your material performance and streamline your production process!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the specific role of a vacuum furnace in ZnS ceramic fabrication? Achieve Optical-Grade Material Purity

- What role does a high-temperature vertical gradient furnace play in the Bridgman method? Master Single Crystal Growth

- What is heat treatment as used in metallic materials? Tailor Metal Properties for Superior Performance

- Why is a vacuum environment system necessary for SEP of CuAlMn alloys? Achieve High-Purity Porous Structures

- How does a high-temperature batch pyrolysis furnace facilitate biomass simulation? Master Material Testing Today

- What is a vacuum casting machine? Achieve Bubble-Free, High-Fidelity Prototypes

- What are the hazards of quenching? Avoid Material Failure and Personnel Injury

- What is the function of a vacuum drying oven in boehmite synthesis? Preserving Particle Integrity and Purity