In modern dentistry, porcelain is the premier material for creating highly aesthetic and durable dental restorations. It is used to fabricate crowns, veneers, bridges, inlays, and onlays that are virtually indistinguishable from natural teeth. Its unique composition allows it to mimic the color, translucency, and strength of tooth enamel with remarkable accuracy.

While often recognized for its strength, dental porcelain's true value lies in its unparalleled ability to replicate the natural beauty of teeth, making it the cornerstone of modern cosmetic and restorative dentistry.

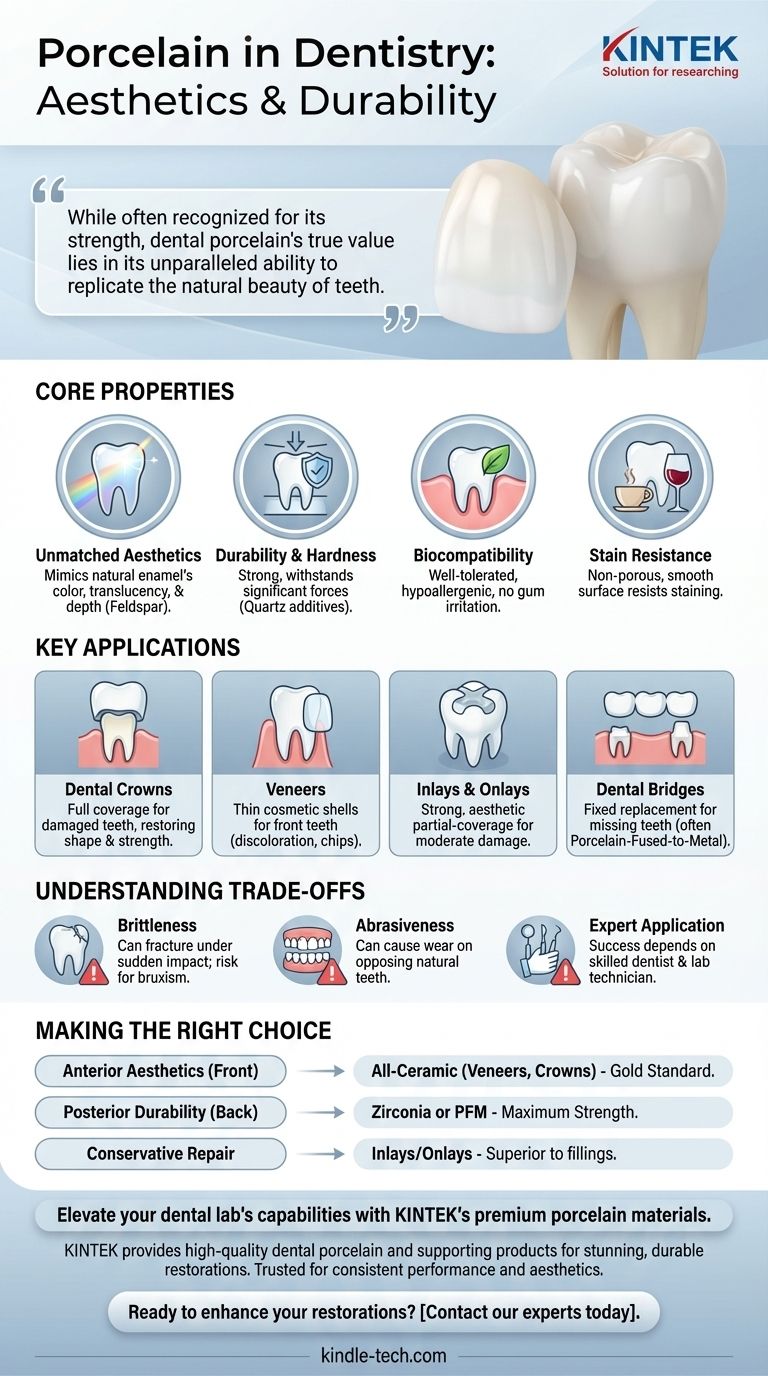

The Core Properties of Dental Porcelain

To understand why porcelain is so widely used, we must first examine its fundamental characteristics. Its composition is key to its performance.

Unmatched Aesthetics

The primary advantage of porcelain is its chameleon-like ability to match the appearance of natural tooth enamel.

The presence of materials like feldspar allows technicians to layer different shades and opacities, creating a depth and translucency that reflects light just like a real tooth.

Durability and Hardness

Dental porcelain is an exceptionally strong and hard material, capable of withstanding the significant forces of chewing and grinding.

Additives like quartz are incorporated into its composition specifically to increase hardness and wear resistance, ensuring the restoration lasts for many years.

Biocompatibility

Porcelain is highly biocompatible, meaning it is well-tolerated by the body and does not cause allergic reactions or irritation to the gum tissues. This makes it a safe and predictable choice for long-term placement in the mouth.

Stain Resistance

Unlike natural tooth enamel or composite resin, porcelain is a ceramic glass that is non-porous. Its smooth, glazed surface is highly resistant to staining from coffee, tea, red wine, and tobacco.

Key Applications in Dental Restorations

These properties make porcelain the ideal material for a wide range of restorative procedures.

Dental Crowns

A full porcelain crown is used to completely cover a damaged or weakened tooth, restoring its original shape, size, strength, and appearance.

Veneers

Veneers are thin, custom-made shells of porcelain bonded to the front surface of teeth. They are a cosmetic solution used to correct issues like discoloration, chips, or gaps.

Inlays and Onlays

For damage that is too extensive for a simple filling but not severe enough for a full crown, porcelain inlays and onlays are used. They are fabricated in a lab and bonded into place, providing a strong and aesthetic partial-coverage restoration.

Dental Bridges

Porcelain is also used to create fixed dental bridges to replace one or more missing teeth. These restorations are often made as Porcelain-Fused-to-Metal (PFM), combining the strength of a metal substructure with the aesthetics of a porcelain overlay.

Understanding the Trade-offs

No material is perfect, and it is important to understand the limitations of dental porcelain to make informed decisions.

Brittleness and Fracture Risk

While porcelain is very hard, it is also a brittle material. Under extreme or sudden impact, it can fracture or chip more easily than a metal-based restoration. This is a key consideration for patients who grind their teeth (bruxism).

Potential for Abrasiveness

Because dental porcelain is so hard, it can cause accelerated wear on the opposing natural teeth over time. This is a factor your dentist will carefully evaluate when planning your restoration.

Requires Expert Application

The success of a porcelain restoration is highly dependent on the skill of both the dentist preparing the tooth and the dental lab technician fabricating the final piece. Proper bonding and precise fitting are critical for longevity.

Making the Right Choice for Your Goal

Selecting the right material always involves balancing aesthetics, function, and durability. The best choice depends entirely on the clinical situation and your specific priorities.

- If your primary focus is anterior (front tooth) aesthetics: All-ceramic porcelain restorations like veneers or crowns are the undisputed gold standard for a seamless, natural look.

- If your primary focus is posterior (back tooth) durability under heavy force: A stronger material like full zirconia or a Porcelain-Fused-to-Metal (PFM) crown may be recommended for maximum strength.

- If your primary focus is a conservative repair with excellent aesthetics: Porcelain inlays and onlays provide a superior alternative to traditional fillings, preserving more healthy tooth structure.

Ultimately, porcelain's unique blend of beauty and resilience makes it one of the most valuable and versatile materials in restorative dentistry.

Summary Table:

| Property | Benefit in Dentistry |

|---|---|

| Aesthetics | Mimics natural tooth color & translucency |

| Durability | Withstands chewing forces for long-lasting restorations |

| Biocompatibility | Safe for gums, hypoallergenic |

| Stain Resistance | Resists discoloration from food/drinks |

Elevate your dental lab's capabilities with KINTEK's premium porcelain materials.

As a specialist in lab equipment and consumables, KINTEK provides the high-quality dental porcelain and supporting products you need to fabricate stunning, durable crowns, veneers, and bridges. Our materials are trusted for their consistent performance and exceptional aesthetics, helping you meet the demanding standards of modern cosmetic and restorative dentistry.

Ready to enhance your restorations? Contact our experts today via our Contact Form to discuss how KINTEK's solutions can benefit your laboratory and patients.

Visual Guide

Related Products

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- 1200℃ Muffle Furnace Oven for Laboratory

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- How do the thermal properties of zirconia substructures influence firing and cooling? Expert Thermal Management Guide

- What is a burnout furnace? The Key to Flawless Precision Casting

- How do some modern press furnaces mitigate problems related to pressing time? Achieve Consistent, Error-Free Dental Pressing

- What is the sintering temperature of zirconia? Achieve Optimal Strength and Aesthetics

- What is the most common dental ceramics? A Guide to Choosing the Right Material

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- How strong are ceramic implants? Discover the Power of Zirconia for a Metal-Free Smile