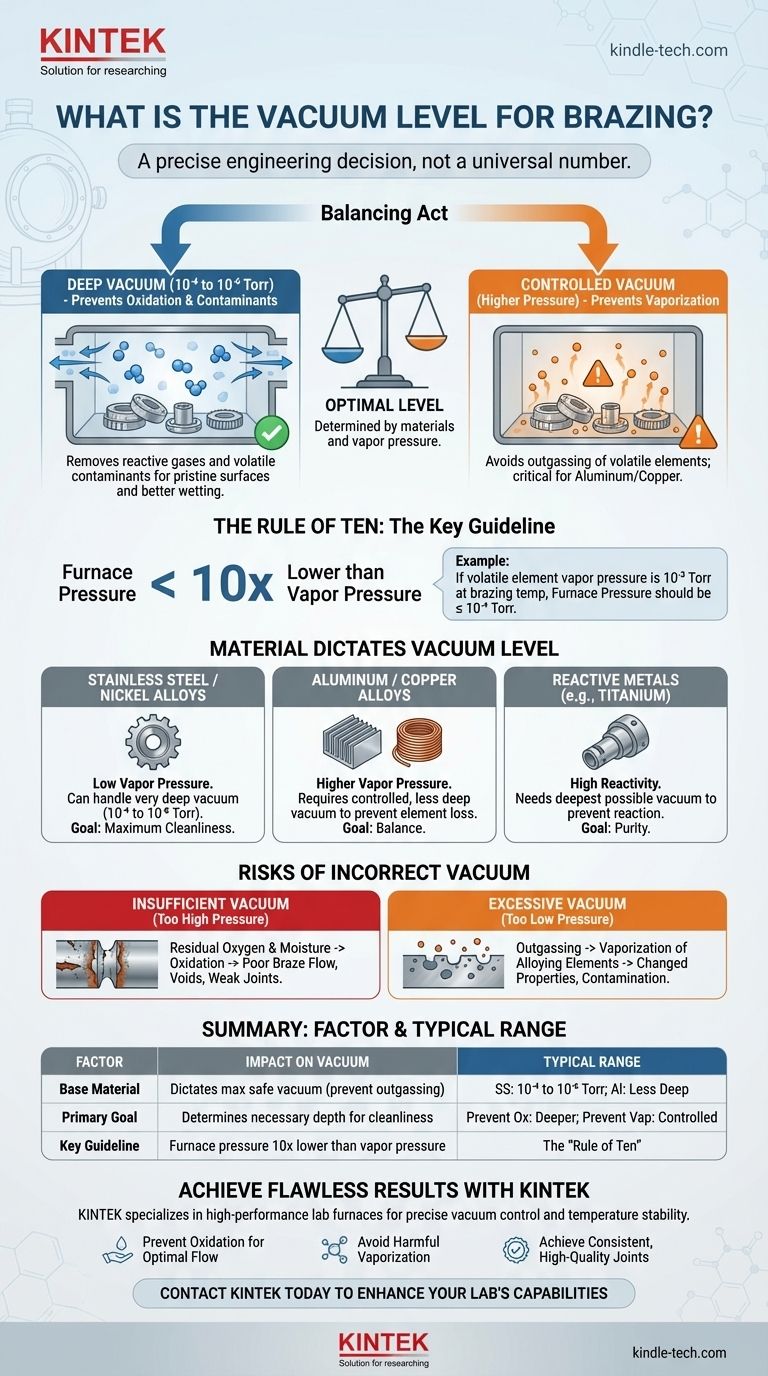

While there is no single universal vacuum level for brazing, the required level is a precise engineering decision dictated by the specific materials being joined. Typical high-vacuum brazing is performed in the range of 10⁻³ to 10⁻⁶ Torr, but the optimal level is determined by the need to prevent oxidation without causing harmful vaporization of the metals themselves.

The correct vacuum level is not a fixed target; it's a dynamic variable determined by the vapor pressure of your base materials and filler alloy. The goal is to create a vacuum deep enough to remove reactive gases like oxygen, but not so deep that it vaporizes essential elements from your components at the brazing temperature.

The Core Purpose of Vacuum in Brazing

Understanding why a vacuum is used is the key to determining the correct level. The vacuum is not just an empty space; it is an active part of the process that controls the chemical environment.

Preventing Oxidation

The primary function of the vacuum is to remove oxygen and other reactive gases from the furnace chamber. At high brazing temperatures, even trace amounts of oxygen will rapidly form oxides on the metal surfaces.

These oxide layers act as a barrier, preventing the molten braze filler metal from properly "wetting" and flowing into the joint, which results in a weak or failed bond.

Removing Volatile Contaminants

The combination of heat and vacuum effectively cleans the parts in-situ. It helps vaporize and remove surface contaminants like residual oils, moisture, and absorbed gases.

This cleaning action is crucial for creating a pristine surface that is ready to form a strong, continuous metallurgical bond with the filler alloy.

Promoting Braze Flow (Wetting)

By ensuring an exceptionally clean, oxide-free surface, the vacuum environment allows the molten filler alloy to flow freely and evenly into the joint through capillary action. This leads to complete joint fill and maximum strength.

How to Determine the Correct Vacuum Level

Instead of memorizing a single number, you must assess the materials involved. The process is governed by the principles of chemistry and physics, specifically vapor pressure.

The Critical Role of Vapor Pressure

Every element has a vapor pressure, which is its tendency to turn into a gas at a given temperature. This tendency increases dramatically with temperature and decreases with surrounding pressure (i.e., in a vacuum).

If the vacuum in your furnace is too deep (the pressure is too low), it can cause elements within your base metal or filler alloy to literally boil away or "outgas" at the brazing temperature.

The "Rule of Ten"

A widely accepted guideline is that the furnace pressure should be at least one order of magnitude (10x) lower than the vapor pressure of the most volatile element in your assembly at the peak brazing temperature.

For example, if an element in your alloy has a vapor pressure of 10⁻³ Torr at your brazing temperature, your furnace vacuum should be 10⁻⁴ Torr or deeper to prevent it from vaporizing.

Material Dictates the Vacuum

This is why different materials demand different vacuum levels.

- Stainless Steels and Nickel Alloys: These have very low vapor pressures, allowing for very deep vacuums (10⁻⁴ to 10⁻⁶ Torr) without risk.

- Aluminum or Copper Alloys: These contain elements with higher vapor pressures. Brazing them requires careful control and often a less deep vacuum to prevent the loss of base metal or alloying elements.

Understanding the Trade-offs

Choosing the wrong vacuum level can be as detrimental as the brazing process itself. Both insufficient and excessive vacuum present significant risks.

The Danger of Insufficient Vacuum (High Pressure)

If the vacuum is not deep enough, residual oxygen and water vapor will remain in the chamber. This will lead to oxidation of the parts as they are heated.

The result is poor braze flow, voids within the joint, and a component that may look brazed but lacks the required structural integrity. This is the most common failure mode related to vacuum levels.

The Danger of Excessive Vacuum (Low Pressure)

A vacuum that is too deep for the specific materials can be destructive. It causes "outgassing," where volatile alloying elements are pulled from the material.

For example, brazing a chromium-bearing alloy in too deep a vacuum can deplete chromium from the surface, reducing its corrosion resistance. Similarly, using zinc- or cadmium-bearing filler metals in a high vacuum will cause these elements to vaporize, changing the filler's properties and contaminating the furnace.

Making the Right Choice for Your Application

Selecting the right vacuum level is a technical decision based on your materials and desired outcome. Consult vapor pressure charts for your specific alloys as the ultimate source of truth.

- If your primary focus is brazing stainless steel, nickel alloys, or refractory metals: Your main goal is cleanliness, so a high vacuum in the 10⁻⁴ to 10⁻⁶ Torr range is generally safe and effective.

- If your primary focus is brazing aluminum or alloys containing volatile elements like copper: You must carefully balance cleanliness with preventing outgassing, often requiring a less deep vacuum and precise temperature control.

- If your primary focus is joining ceramics or reactive metals like titanium: The deepest possible vacuum is often required to prevent any reaction with residual gases and ensure a pure, strong bond.

Ultimately, mastering vacuum brazing comes from understanding that the vacuum level is a precise tool to control the material's environment, not just a number to be reached.

Summary Table:

| Factor | Impact on Vacuum Level | Typical Range |

|---|---|---|

| Base Material | Dictates maximum safe vacuum to prevent outgassing | Stainless Steel: 10⁻⁴ to 10⁻⁶ Torr; Aluminum: Less Deep |

| Primary Goal | Determines necessary vacuum depth for cleanliness | Prevent Oxidation: Deeper Vacuum; Prevent Vaporization: Controlled Vacuum |

| Key Guideline | Furnace pressure should be 10x lower than the vapor pressure of the most volatile element | The 'Rule of Ten' |

Achieve Flawless Brazing Results with KINTEK

Navigating the precise balance of vacuum levels is critical for successful brazing. Whether you're working with stainless steel, aluminum, or reactive metals, the right equipment and expertise make all the difference.

KINTEK specializes in high-performance lab furnaces and consumables designed to deliver the precise vacuum control and temperature stability your brazing processes demand. Our solutions help you:

- Prevent Oxidation: Ensure clean, oxide-free surfaces for optimal braze flow.

- Avoid Harmful Vaporization: Protect your materials from outgassing and element loss.

- Achieve Consistent, High-Quality Joints: Maximize the strength and integrity of your assemblies.

Don't let vacuum level uncertainty compromise your results. Let our experts help you select the perfect system for your specific materials and application requirements.

Contact KINTEK today to discuss your brazing needs and discover how our specialized equipment can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why must copper foil electrodes undergo high-temperature drying in a vacuum oven? Optimize Li6PS5Cl Cell Assembly

- What is the plasma arc technology? A Guide to Advanced Material Processing

- Why is a vacuum drying oven preferred for drying ceramic slurries? Prevent Oxidation & Ensure Chemical Purity

- What is the process of vacuum tempering? Achieve a Perfect Balance of Hardness and Toughness

- Why are some furnaces equipped with a second high temperature chamber? For Clean, Compliant Combustion

- What is plasma torch gasification as a method to dispose hazardous waste? Convert Hazardous Waste into Clean Energy & Inert Slag

- Is quenching part of annealing? No, and Here's the Critical Difference You Need to Know

- What is the secondary melting process? Achieve Superior Metal Purity for Critical Applications