In the world of high-performance metals, Vacuum Arc Remelting (VAR) is not a primary steelmaking method, but a secondary refining process designed to create exceptionally clean and uniform alloys. It takes a solid, pre-made steel bar (called an electrode) and remelts it drop by drop under a powerful vacuum. This purifies the metal by removing dissolved gases and other impurities, resulting in a final product with vastly superior mechanical properties required for critical applications.

The core purpose of VAR is not to make steel, but to perfect it. It's a purification step that transforms a good alloy into an ultra-reliable material by removing the microscopic flaws that cause failures under extreme stress.

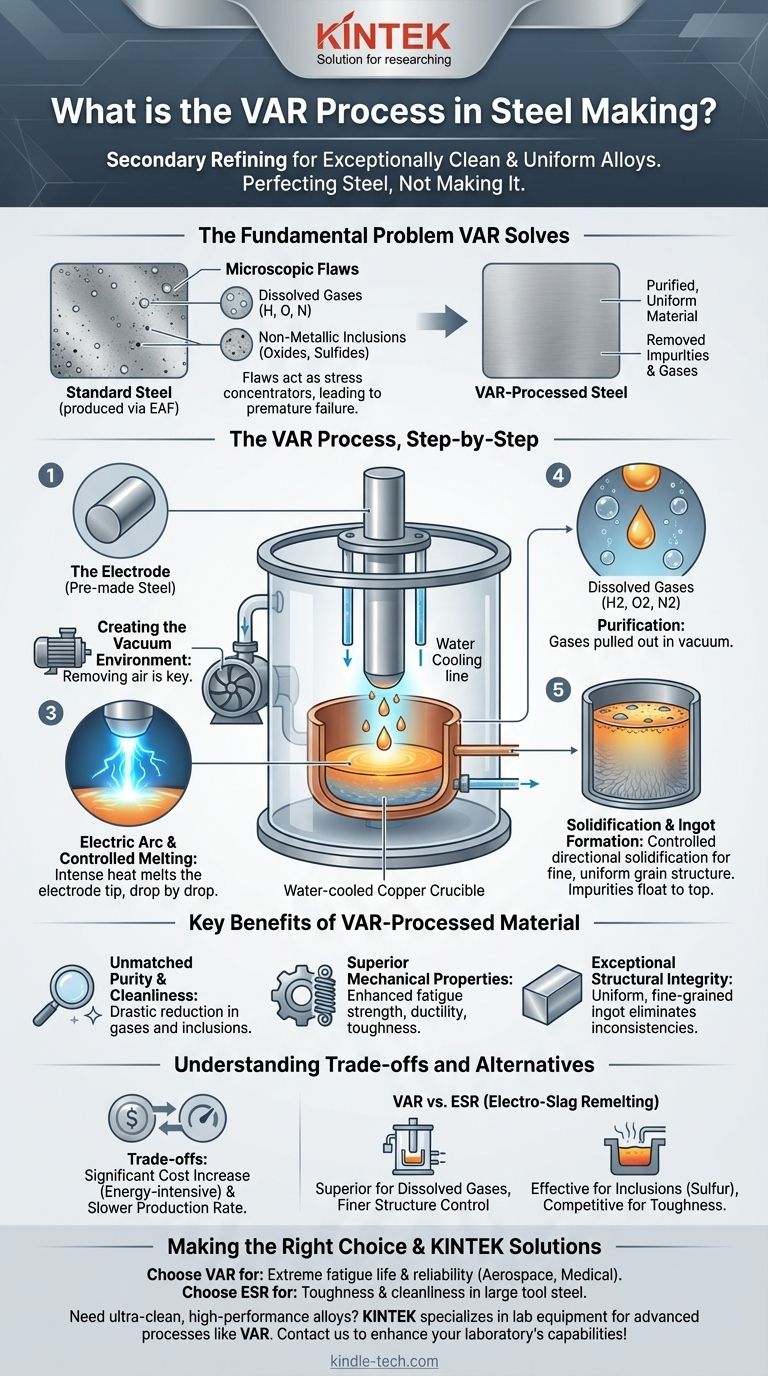

The Fundamental Problem VAR Solves

To understand the need for VAR, you must first understand the limitations of conventional steel production.

Microscopic Flaws in Standard Steel

Primary steelmaking processes, like the Electric Arc Furnace (EAF), are excellent for producing large volumes of steel. However, they inevitably leave behind residual impurities.

These impurities fall into two categories: dissolved gases (like hydrogen, oxygen, and nitrogen) and non-metallic inclusions (like tiny oxides and sulfides).

The Role of Flaws in Material Failure

These microscopic flaws act as stress concentrators. Under cyclic loading (fatigue) or high tensile stress, cracks can initiate at these points, leading to premature and often catastrophic failure of a component. For general construction, this risk is acceptable. For a jet engine turbine disc, it is not.

The VAR Process, Step-by-Step

VAR systematically removes these flaws through a highly controlled remelting process inside a vacuum.

The Starting Point: The Electrode

The process begins with a solid cylinder of the alloy to be purified, known as an electrode. This electrode has already been produced through a primary melting process like EAF or even Vacuum Induction Melting (VIM) for higher quality starting stock.

Creating the Vacuum Environment

The electrode is suspended inside a sealed, water-cooled copper crucible. A powerful vacuum system then removes the air from the chamber. This vacuum is the key to the entire process.

The Electric Arc and Controlled Melting

An electric arc is struck between the bottom of the electrode and a small amount of starting material at the base of the crucible. The intense heat of the arc melts the tip of the electrode.

As the metal melts, it drips down. While in its molten state and exposed to the vacuum, dissolved gases are literally pulled out of the liquid metal.

Solidification and Ingot Formation

The molten metal collects in the water-cooled copper crucible and begins to solidify from the bottom up in a highly controlled, directional manner. This controlled solidification prevents the formation of coarse, random crystal structures and promotes a fine, uniform grain structure.

Any remaining solid inclusions tend to be less dense than the molten metal, allowing them to float to the top of the molten pool, where they are effectively segregated from the final, usable ingot.

Key Benefits of a VAR-Processed Material

The result of this meticulous process is a new ingot with fundamentally improved characteristics.

Unmatched Purity and Cleanliness

The primary benefit is a drastic reduction in dissolved gases and the size and quantity of non-metallic inclusions. This material "cleanliness" is the foundation for all other improvements.

Superior Mechanical Properties

By removing the microscopic points of failure, VAR processing significantly enhances critical properties. This includes improved fatigue strength, ductility, toughness, and overall fracture resistance.

Exceptional Structural Integrity

The controlled, directional solidification creates an extremely uniform (homogeneous) and fine-grained ingot structure. This eliminates the chemical and structural inconsistencies found in conventionally cast ingots, ensuring that the material's properties are consistent throughout the entire component.

Understanding the Trade-offs and Limitations

While VAR produces superior metals, it is not a universally applied process due to its specific trade-offs.

Significant Cost Increase

VAR is an energy-intensive and time-consuming secondary process. This adds considerable cost compared to standard air-melted alloys.

Slower Production Rate

The controlled nature of the melting and solidification means that VAR is a much slower production method than primary steelmaking, limiting its use to applications where the performance benefits justify the time and expense.

Comparison to Electro-Slag Remelting (ESR)

VAR's primary alternative is Electro-Slag Remelting (ESR). In ESR, the electrode is also remelted, but it drips through a molten, highly reactive slag bath instead of a vacuum.

This slag bath acts like a chemical sponge, absorbing certain impurities like sulfur. While ESR is very effective at removing oxide and sulfide inclusions, VAR is superior at removing dissolved gases and offers finer control over the solidification structure.

Making the Right Choice for Your Application

Selecting a VAR-processed material is a decision driven entirely by the performance and reliability demands of the final component.

- If your primary focus is extreme fatigue life and reliability (aerospace, medical): VAR is the industry standard for its ability to remove gases and create a flawless microstructure.

- If your primary focus is toughness and cleanliness in large tool steel sections: ESR is often a competitive and effective alternative to VAR, particularly for its ability to remove sulfur.

- If your application is for general structural or commercial use: VAR is almost certainly an unnecessary and cost-prohibitive level of refinement.

Ultimately, understanding this process allows you to specify the precise level of material integrity your critical application demands.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Vacuum Melting | Removes dissolved gases (H2, O2, N2) |

| Controlled Solidification | Creates uniform, fine-grained structure |

| Directional Solidification | Reduces inclusions and segregation |

| Secondary Refining | Improves fatigue strength, ductility, and toughness |

Need ultra-clean, high-performance alloys for your critical applications? KINTEK specializes in lab equipment and consumables that support advanced metallurgical processes like VAR. Whether you're in aerospace, medical, or high-tech manufacturing, our solutions help you achieve the material integrity your projects demand. Contact us today to discuss how we can enhance your laboratory's capabilities!

Visual Guide

Related Products

- Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is induction furnace used for? Achieve Fast, Clean Metal Melting and Heat Treatment

- What are the factors affecting the rate of melting process? Master Heat Transfer for Faster Results

- Does induction heating work on titanium? Mastering the Process for Aerospace & Medical Alloys

- Which furnace is most commonly used for melting non ferrous metals? Induction Furnaces for Purity & Efficiency

- What is the temperature range of induction heating? From Gentle Warming to Extreme Melting

- What are the disadvantages of an induction furnace? Key Limitations in Metal Melting

- What advantages does a high-frequency induction heater offer over traditional methods for high-temp fatigue testing?

- What are the hazards of an induction furnace? A Guide to Preventing Catastrophic Failures