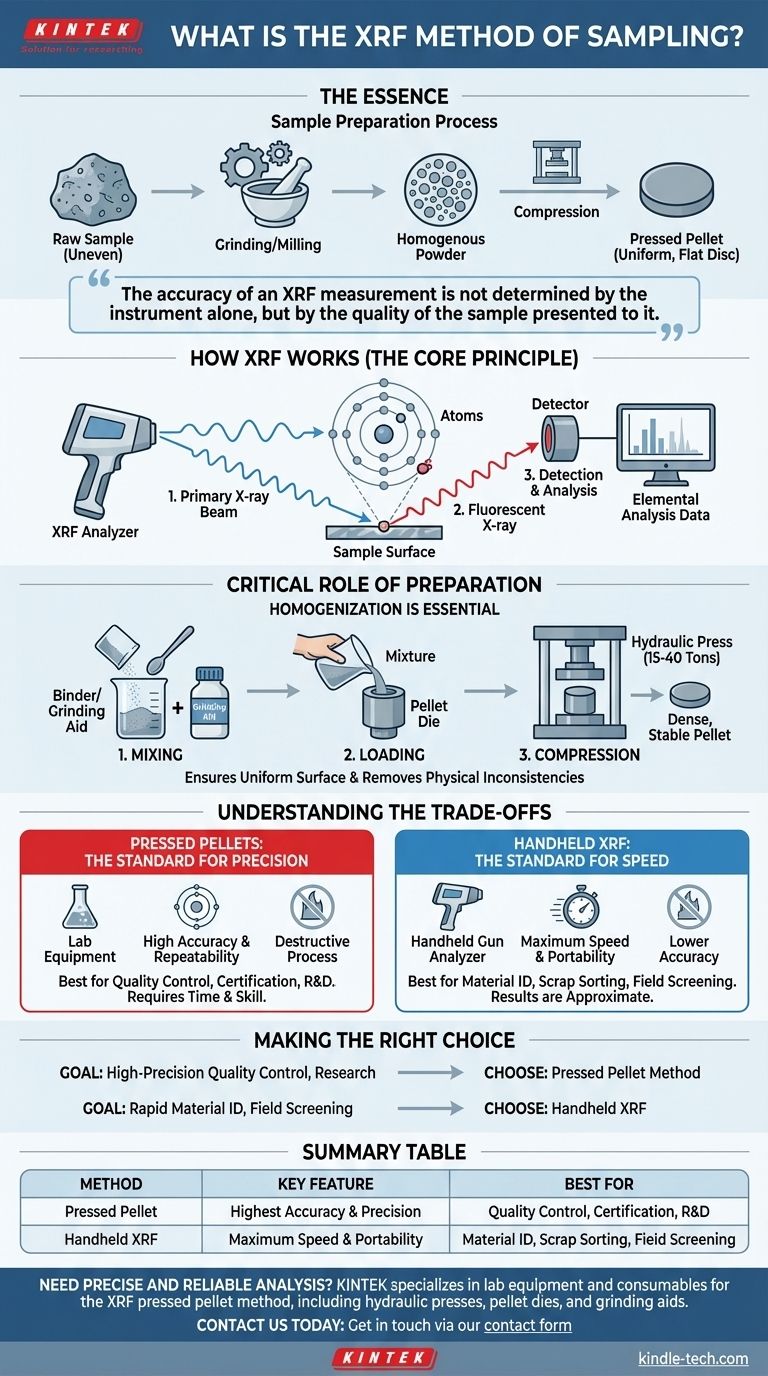

In essence, the XRF method of sampling is not one single technique, but a process of preparing a material to ensure it can be accurately analyzed by an X-ray fluorescence (XRF) instrument. This involves transforming a raw, potentially uneven sample into a uniform, flat disc called a pressed pellet. The quality of this preparation is the single most important factor in achieving reliable and precise elemental analysis.

The accuracy of an XRF measurement is not determined by the instrument alone, but by the quality of the sample presented to it. The core principle of XRF sampling is to eliminate physical inconsistencies in a material to reveal its true chemical composition.

The Core Principle: How XRF Works

To understand why sample preparation is so critical, you must first understand the basic physics of X-ray fluorescence. The entire process relies on consistent interaction between the instrument and the sample surface.

The Initial X-ray Beam

An XRF analyzer generates a primary beam of high-energy X-rays. This beam is directed at the surface of the sample being tested.

Elemental Fluorescence

When these X-rays strike atoms within the sample, they can dislodge electrons from their inner shells. To regain stability, an electron from a higher-energy outer shell immediately drops down to fill the vacancy, releasing a small burst of energy as a secondary, or "fluorescent," X-ray.

Detection and Analysis

Critically, the energy of this fluorescent X-ray is a unique signature of the element it came from. The instrument's detector captures these secondary X-rays, counts them, and measures their specific energies to determine which elements are present and in what concentrations.

The Critical Role of Sample Preparation

The XRF instrument only analyzes the very top layer of the sample. If that surface isn't a perfect representation of the entire material, the results will be inaccurate. The pressed pellet method is designed to solve this problem.

Homogenization is Essential

Most raw materials, from soil to metal alloys, are not perfectly uniform. This lack of homogeneity means a small sample taken from one spot might have a different composition than a sample taken from another.

To fix this, the bulk sample is first milled or ground into an extremely fine, consistent powder. This ensures that the elemental distribution is averaged out across the entire sample.

Creating the Pressed Pellet

Once the sample is a homogenous powder, it is prepared for the analyzer. This process typically involves three steps.

- Mixing: The powder is mixed with a specific binder or grinding aid. This helps the sample particles stick together under pressure.

- Loading: The mixture is carefully poured into a high-strength steel cylinder known as a pellet die.

- Compression: The die is placed in a hydraulic press and subjected to immense pressure, typically between 15 and 40 tons. This compacts the powder into a dense, solid disc with a perfectly flat and stable surface.

This flat, homogenous pellet ensures that the X-ray beam interacts with the material uniformly, eliminating errors caused by surface roughness, voids, or variations in density.

Understanding the Trade-offs

The pressed pellet method is the gold standard for accuracy, but it's not the only way to perform XRF analysis. The right method depends entirely on your goal.

Pressed Pellets: The Standard for Precision

This laboratory-based method provides the highest level of accuracy and repeatability. By eliminating physical variations, it allows the instrument to measure the true chemical composition.

The trade-off is that it is a destructive process that requires time, specialized equipment (grinders, presses), and a skilled operator. It is not suitable for rapid field analysis.

Handheld XRF: The Standard for Speed

Modern handheld XRF analyzers (often called "XRF guns") perform the same physical process but are designed for portability and speed. The user simply points the analyzer at the material and pulls a trigger.

The trade-off is lower accuracy. Without the rigorous sample preparation of the pellet method, results are highly susceptible to surface condition, shape, and lack of homogeneity. It is best used for sorting materials or for screening tests where absolute precision is not the primary goal.

Making the Right Choice for Your Goal

Selecting the correct sampling approach is fundamental to getting data you can trust. Your application dictates the necessary level of rigor.

- If your primary focus is high-precision quality control, certification, or research: The pressed pellet method is the only way to guarantee the accuracy required for these applications.

- If your primary focus is rapid material identification, scrap sorting, or initial field screening: A handheld XRF analyzer provides the necessary speed and convenience, with the understanding that the results are approximate.

Ultimately, understanding the relationship between sample preparation and data quality empowers you to choose the right tool for the job.

Summary Table:

| Method | Key Feature | Best For |

|---|---|---|

| Pressed Pellet | Highest Accuracy & Precision | Quality Control, Certification, R&D |

| Handheld XRF | Maximum Speed & Portability | Material ID, Scrap Sorting, Field Screening |

Need precise and reliable elemental analysis for your laboratory? The quality of your sample preparation directly determines the accuracy of your results. KINTEK specializes in the lab equipment and consumables essential for the XRF pressed pellet method, including hydraulic presses, pellet dies, and grinding aids. Our solutions help you achieve the homogeneity and flat surfaces required for trustworthy data.

Contact us today to discuss your application and ensure your sampling process is optimized for success. Get in touch via our contact form to speak with an expert.

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- What role does a uniaxial hydraulic press play in the fabrication of NaSICON ceramic cylinders? Pre-forming Excellence

- Why is a 350 MPa laboratory hydraulic press necessary for sulfide solid-state electrolytes? Achieve peak density.

- What are the preventive maintenance of hydraulic systems? Extend Equipment Life and Maximize Uptime

- What is C type and H type power press? Choose the Right Press for Precision or Accessibility

- What is a hydraulic press used for? From Metal Forging to Lab Sample Prep

- Why is a laboratory hydraulic press required for electrolyte densification? Unlock High-Performance Solid-State Batteries

- How does the pressing pressure of a laboratory hydraulic press affect Ni–Cr alloys? Optimize Density & Strength

- What is the sample size for micro XRF? The Key to Accurate Microscopic Elemental Mapping