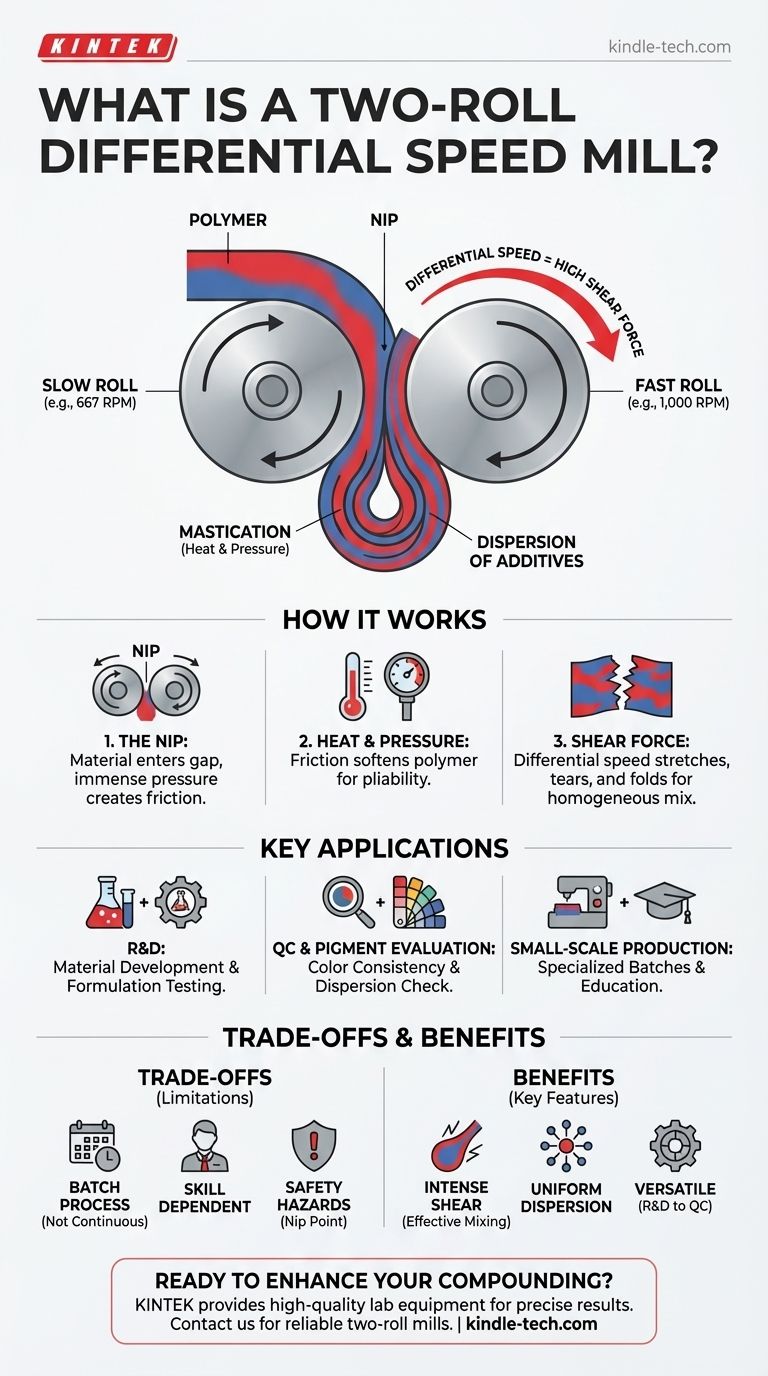

At its core, a two-roll differential speed mill is a compounding machine used to mix and process polymers like rubber and plastics. It consists of two counter-rotating horizontal rollers that operate at slightly different speeds, creating a high-shear environment to effectively blend materials, disperse additives like pigments, and ensure a uniform, homogeneous final product.

The critical concept is not just the presence of two rollers, but the differential speed between them. This speed difference is what generates the intense shear force required to break down, fold, and thoroughly mix the polymer matrix with its additives.

How a Two-Roll Mill Creates a Homogeneous Mix

The effectiveness of a two-roll mill comes from a precise combination of pressure, heat, and, most importantly, shear. Each element plays a distinct role in the compounding process.

The Role of the Nip

The material to be mixed is introduced into the gap between the two rollers, an area known as the nip. As the rollers turn, they pull the material through this tight space, creating immense pressure.

Heat and Pressure

The friction and pressure generated within the nip create significant heat. This heat softens the polymer, making it pliable and receptive to mixing, a process often referred to as mastication.

The Critical Function of Shear Force

This is where differential speed becomes essential. Because one roll turns faster than the other, the material is stretched and torn as it passes through the nip. This shearing action is what folds the polymer over itself repeatedly.

A common setup is a 1.5:1 ratio, where the fast roll might turn at 1,000 RPM while the slow roll turns at 667 RPM. This constant tearing and folding ensures that any added pigments, fillers, or chemicals are thoroughly and evenly dispersed throughout the polymer base.

Key Industrial and Laboratory Applications

The two-roll mill is a versatile tool found in both production environments and research labs for a variety of critical tasks.

Material Development and Formulation

In research and development, mills are used for mixing tests on new polymer formulations. They allow engineers and scientists to create and evaluate small test batches of new materials efficiently.

Pigment and Masterbatch Evaluation

The mill is an industry standard for testing the quality of color masterbatch. It quickly reveals how well a pigment disperses within a specific polymer, ensuring color uniformity in the final plastic or rubber product.

Quality Control and Consistency

For quality control, samples from a production line can be run through a mill. This helps verify that the material meets consistency standards and that additives are uniformly distributed from one batch to the next.

Understanding the Trade-offs

While powerful, the two-roll mill is not the ideal solution for every compounding task. Its design comes with inherent limitations.

Primarily a Batch Process

Unlike a twin-screw extruder which can run continuously, a two-roll mill is a batch machine. Material is processed one batch at a time, making it less suitable for high-volume, continuous manufacturing.

Operator Skill Dependency

The quality of the final mix can be heavily influenced by the skill of the operator. The process of cutting the material off the roll and feeding it back into the nip to ensure a homogeneous blend requires experience and technique.

Significant Safety Hazards

The nip point between the powerful, rotating rollers presents a serious entanglement hazard. Modern mills are equipped with extensive safety features, but operator training and awareness remain critical to prevent injury.

Making the Right Choice for Your Goal

Ultimately, the value of a two-roll mill depends entirely on your specific objective.

- If your primary focus is Research & Development: It is an indispensable tool for rapidly testing new formulations and evaluating the performance of additives.

- If your primary focus is Quality Control: It provides a reliable method for verifying pigment dispersion and ensuring batch-to-batch material consistency.

- If your primary focus is Education or Small-Scale Production: It serves as an excellent machine for demonstrating polymer processing principles and producing small, highly specialized batches of material.

By understanding the principle of differential speed, you can effectively leverage the two-roll mill for precise and repeatable material compounding.

Summary Table:

| Feature | Benefit |

|---|---|

| Differential Speed | Creates intense shear force for effective mixing and folding. |

| Batch Processing | Ideal for R&D, quality control, and small-scale production. |

| High-Shear Environment | Ensures uniform dispersion of pigments, fillers, and chemicals. |

| Versatile Applications | Used in material development, masterbatch evaluation, and QC. |

Ready to enhance your polymer compounding process?

A two-roll differential speed mill is essential for achieving a homogeneous mix in R&D and quality control. KINTEK specializes in providing high-quality lab equipment, including reliable two-roll mills, to meet your specific laboratory needs for polymer and rubber testing.

Contact us today to discuss how our equipment can help you achieve precise and repeatable results. Get in touch with our experts now!

Visual Guide

Related Products

- Open Type Two Roll Mixing Mill Machine for Rubber Crusher

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Lab Internal Rubber Mixer Rubber Kneader Machine for Mixing and Kneading

- Laboratory Hybrid Tissue Grinding Mill

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

People Also Ask

- What is the difference between Banbury and internal mixer? Understanding Rotor Design for Better Mixing

- What is a two-high roll mill? Master Precise Material Compounding and Testing

- What is the disadvantage of a two-roll mill? Limited Thickness Reduction Due to Roll Flattening

- What is meant by two high rolling mill? A Guide to Core Material Processing

- What is the use of two roll mill? Essential for Polymer Mixing, R&D, and Quality Control