For heat treating, the industry-standard instrument used to measure and monitor high temperatures is the thermocouple. This robust sensor is essential for the precise thermal control required to achieve specific metallurgical properties in materials, making it a cornerstone of process quality and consistency.

The challenge isn't merely measuring temperature; it's ensuring that the measurement is accurate, repeatable, and truly representative of the material being treated. This requires not just the right sensor, but a rigorous system of calibration, placement, and verification.

The Core Instrument: Understanding the Thermocouple

Heat treatment success is fundamentally tied to accurate temperature control. The thermocouple is the primary tool used to achieve this due to its unique combination of durability, range, and cost-effectiveness.

How a Thermocouple Works

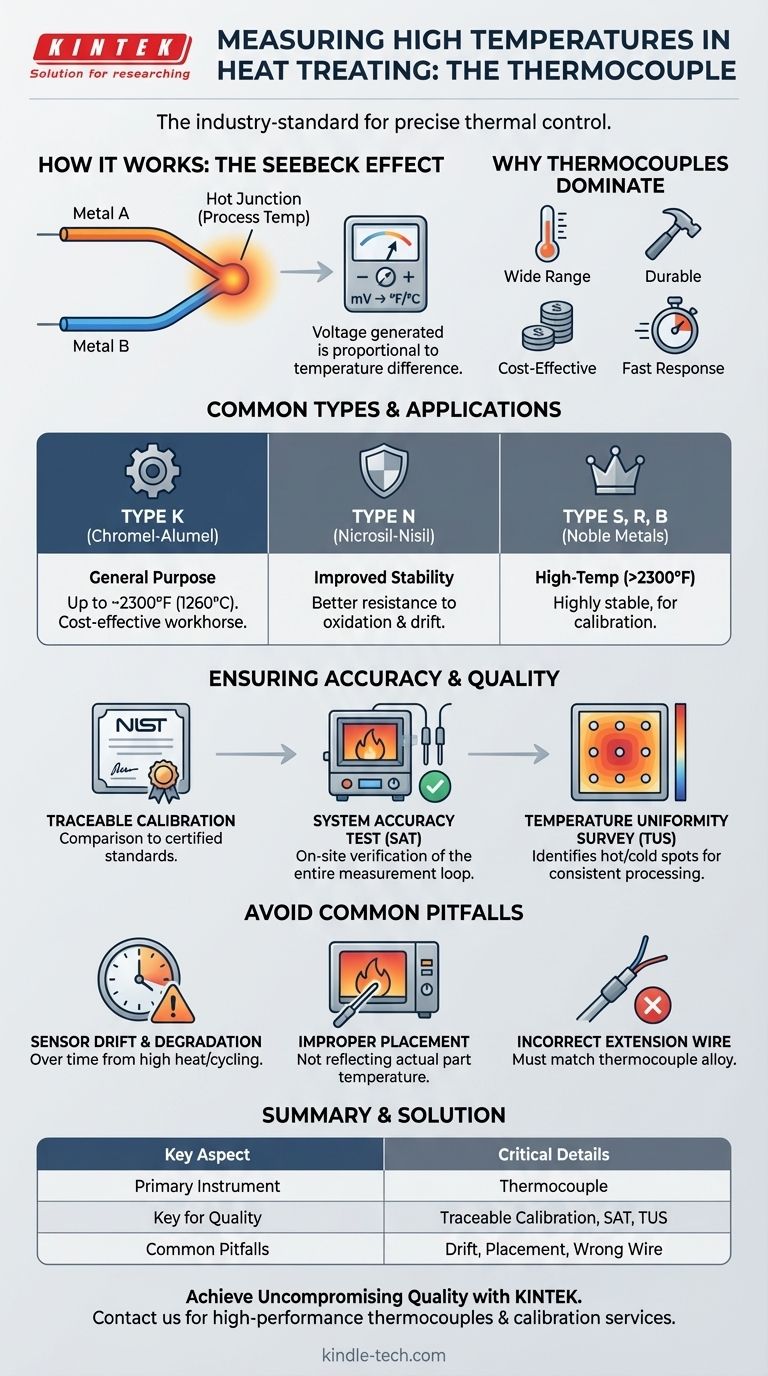

A thermocouple operates on a simple principle called the Seebeck effect. It consists of two wires made from different metals joined at one end (the "hot junction").

When this junction is heated, a small, predictable voltage is generated, which is directly proportional to the temperature. An instrument then reads this voltage and converts it into a temperature reading.

Why Thermocouples Dominate Heat Treating

While other sensors exist, thermocouples are preferred in this environment for several key reasons.

They offer a very wide temperature range, are mechanically durable, relatively inexpensive, and can respond quickly to temperature changes.

Common Thermocouple Types in Heat Treating

Different metal pairings are used to create thermocouples for specific applications. The most common types in heat treating are designated by letters.

- Type K (Chromel-Alumel): The industry workhorse. It's cost-effective and suitable for most general-purpose heat treating in air or inert atmospheres up to about 2300°F (1260°C).

- Type N (Nicrosil-Nisil): An improved alternative to Type K. It offers better stability and resistance to high-temperature oxidation, leading to a longer service life and less drift.

- Type S, R, and B (Noble Metals): These are made from platinum-rhodium alloys. They are used for high-temperature applications above 2300°F and are highly stable, making them the standard for calibrating other thermocouples.

Ensuring Accuracy: Calibration and System Checks

A thermocouple is only as reliable as the system it's part of. For industries like aerospace and automotive, proving this accuracy is a strict requirement.

The Importance of Traceable Calibration

Calibration ensures your instrument's readings are accurate. It involves comparing the thermocouple's output to a known, certified standard.

This process must be traceable, meaning there is an unbroken chain of comparisons back to a national standards body, such as the National Institute of Standards and Technology (NIST).

System Accuracy Tests (SAT)

An SAT is a practical, on-site check of the entire temperature measurement system. A calibrated test thermocouple is placed next to the furnace's control thermocouple to verify that the reading on the instrument display is accurate under actual operating conditions.

This test accounts for any potential errors in the thermocouple, extension wires, and the controller itself.

Temperature Uniformity Surveys (TUS)

A TUS ensures that the temperature is consistent throughout the entire working volume of the furnace. Multiple test thermocouples are placed in a grid pattern inside the furnace.

This survey identifies any hot or cold spots, guaranteeing that every part in a batch receives the exact same thermal processing, regardless of its position.

Understanding the Trade-offs and Common Pitfalls

Relying on temperature readings without understanding their potential for error can lead to failed batches and compromised material quality.

Thermocouple Drift and Degradation

Thermocouples do not last forever. Exposure to high temperatures, aggressive atmospheres, and thermal cycling causes the metals to degrade, which makes their readings "drift" over time.

This is why regular replacement and system checks (like the SAT) are critical for maintaining process control.

The Risk of Improper Placement

A thermocouple only measures the temperature at its tip. If it is placed incorrectly—for example, touching a heating element or far away from the parts—it will provide a false reading of the actual part temperature.

The sensor must be positioned to accurately reflect the thermal conditions the workpiece is experiencing.

Extension Wire Errors

A common and easily avoidable mistake is using the wrong type of extension wire to connect the thermocouple to the control instrument.

This wire must be made of the same or compensating alloys as the thermocouple itself. Using a simple copper wire will introduce significant errors in the temperature reading.

Making the Right Choice for Your Goal

Selecting and managing your temperature measurement system depends entirely on your process requirements and quality standards.

- If your primary focus is general-purpose furnace control: Type K or Type N thermocouples offer the best balance of performance and cost for applications below 2300°F.

- If your primary focus is high-temperature applications or calibration: Noble metal thermocouples like Type S or R are required for their accuracy and stability at extreme temperatures.

- If your primary focus is quality compliance (e.g., Nadcap, CQI-9): A rigorous schedule of traceable calibrations, System Accuracy Tests, and Temperature Uniformity Surveys is non-negotiable.

Ultimately, precise and verifiable temperature control is the absolute foundation of reliable and repeatable heat treatment.

Summary Table:

| Key Aspect | Critical Details |

|---|---|

| Primary Instrument | Thermocouple |

| Common Types | Type K (General use), Type N (Improved stability), Type S/R/B (High-temp/Calibration) |

| Key for Quality | Traceable Calibration, System Accuracy Tests (SAT), Temperature Uniformity Surveys (TUS) |

| Common Pitfalls | Sensor Drift, Improper Placement, Incorrect Extension Wires |

Achieve Uncompromising Quality in Your Heat Treating Processes

Precise temperature control is the foundation of successful heat treatment, directly impacting material properties and product integrity. KINTEK specializes in providing the robust lab equipment and consumables—including high-performance thermocouples and calibration services—that laboratories and manufacturing facilities rely on for accurate, repeatable results.

Don't let temperature measurement uncertainty compromise your quality standards. Contact our experts today to ensure your thermal monitoring system is optimized for peak performance and compliance.

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Thermally Evaporated Tungsten Wire for High Temperature Applications

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why is graphite foil used in ZnS hot pressing? Enhance Purity and Protect Your Molds

- What is an oil-free diaphragm vacuum pump? The Ultimate Guide to Clean, Low-Maintenance Vacuum

- Why are alumina and graphite powder used as auxiliary consumables in tube furnace heat treatment? Prevent Degradation

- What is the function of high-precision Mass Flow Controllers (MFC) in cyclic experiments? Ensure Reliable Simulations

- Why are zirconia grinding balls used for MAX phase ceramic powder? Efficiency Meets Material Purity

- What are the advantages of high-purity graphite sample holders? Ensure Precision in C-C Composite Brazing

- What does a furnace air pressure switch do? Prevent Dangerous Gas Buildup in Your Home

- Why are yttria-stabilized zirconia grinding media preferred for Si2N2O? Master High-Purity Ceramic Milling