In short, vacuum carburizing is a high-performance case-hardening process used to increase the surface hardness of steel components. It involves heating steel in a vacuum and then introducing a carbon-rich gas, like propane. By performing this in a vacuum, the process achieves superior control, uniformity, and speed compared to traditional atmospheric methods.

At its core, the primary advantage of vacuum carburizing is the elimination of atmospheric variables. This allows for a purely chemical interaction between the carbon source and the steel, resulting in a cleaner, faster, and more precise hardening process for critical components.

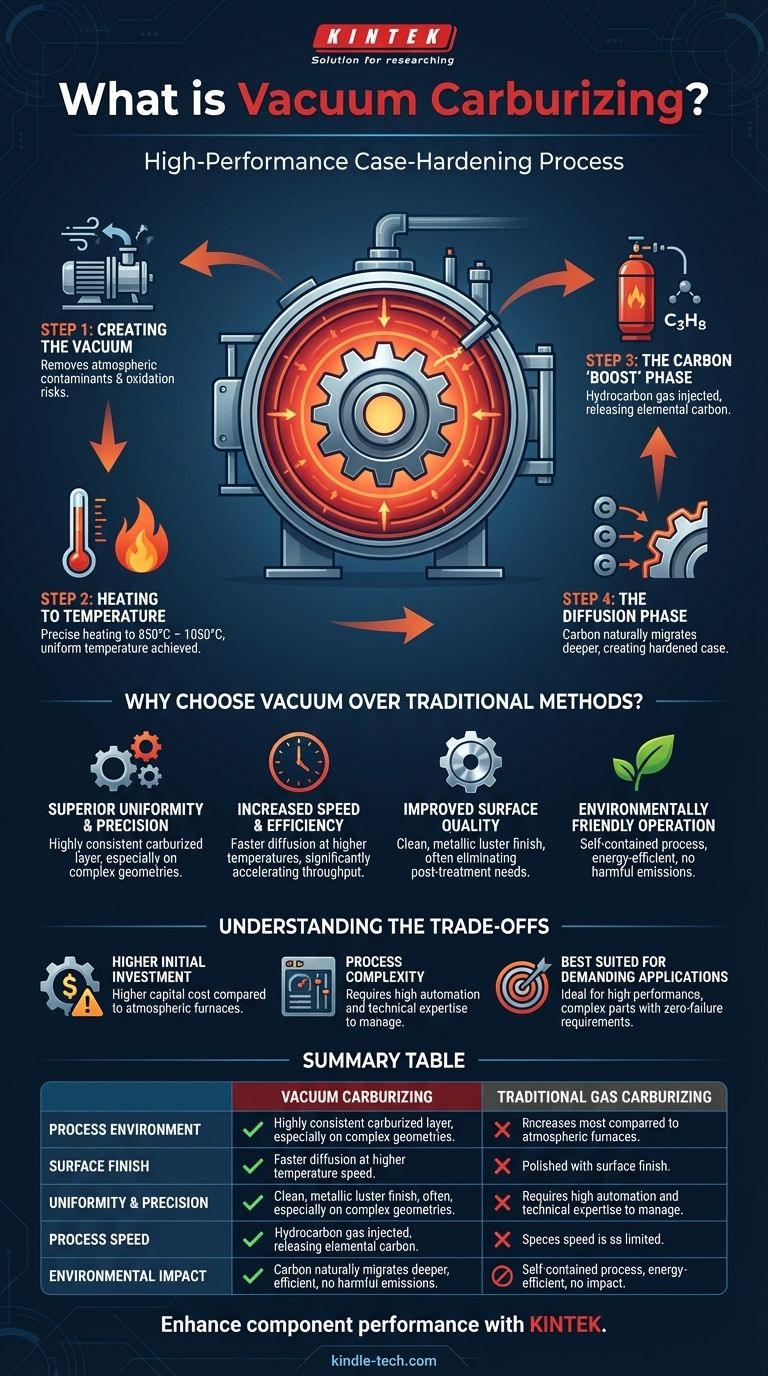

How Vacuum Carburizing Works: A Step-by-Step Breakdown

The vacuum carburizing process is a carefully controlled sequence of heating and chemical exposure designed to create a hard, wear-resistant surface layer (the "case") on a component while maintaining a softer, more ductile core.

Step 1: Creating the Vacuum

First, the steel parts are loaded into a sealed furnace chamber. The air is then pumped out, creating a vacuum. This step is critical as it removes oxygen and other atmospheric contaminants that can interfere with the process and cause surface oxidation.

Step 2: Heating to Temperature

With the vacuum established, the furnace heats the parts to a specific carburizing temperature, typically between 850°C and 1050°C. The heating rate can be precisely controlled, ensuring all parts, regardless of their shape or thickness, reach a uniform temperature.

Step 3: The Carbon "Boost" Phase

Once at temperature, a precise amount of a hydrocarbon gas, most commonly propane (C₃H₈), is injected into the chamber. The intense heat causes this gas to break down (or "crack"), releasing elemental carbon onto the surface of the steel.

Step 4: The Diffusion Phase

After the carbon "boost," the gas supply is shut off. The process then relies on pure diffusion, where the high concentration of carbon on the surface naturally migrates deeper into the steel. This creates the hardened case layer with a predictable and uniform depth. The cycle of boosting and diffusing can be repeated to achieve deeper cases.

Why Choose Vacuum Over Traditional Methods?

The decision to use vacuum carburizing is driven by the need for superior outcomes in demanding applications. It directly addresses the shortcomings of older methods like conventional gas or pack carburizing.

Superior Uniformity and Precision

Traditional gas carburizing can lead to uneven case depths, especially on parts with complex geometries or varying wall thicknesses. Vacuum carburizing solves this by ensuring uniform heating and providing precise, computer-controlled gas injection, resulting in a highly consistent carburized layer.

Increased Speed and Efficiency

The process can operate at higher temperatures without risk of oxidation, which significantly accelerates carbon diffusion. For example, treating a large bevel gear can take half the time compared to gas carburizing, dramatically increasing throughput.

Improved Surface Quality

Parts emerge from a vacuum furnace with a clean, metallic luster, free from the surface oxides common in atmospheric processes. This superior finish often reduces or eliminates the need for post-treatment cleaning or machining.

Environmentally Friendly Operation

Unlike traditional methods that can release byproducts into the atmosphere, vacuum carburizing is a self-contained process. It uses energy only when needed and does not produce harmful emissions, making it a much cleaner technology.

Understanding the Trade-offs

While powerful, vacuum carburizing is not the default solution for every application. Its advantages come with specific considerations.

Higher Initial Investment

Vacuum furnace systems are technologically sophisticated and represent a significantly higher capital investment compared to standard atmospheric furnaces. This cost must be justified by the need for high performance and process quality.

Process Complexity

The high degree of automation and computer control that enables precision also demands a higher level of technical expertise. Setting up, programming, and maintaining a vacuum carburizing system is more complex than managing a conventional furnace.

Best Suited for Demanding Applications

For simple components where ultimate precision is not the primary driver, the benefits of vacuum carburizing may not outweigh the cost. Its strengths are most apparent in high-performance applications with complex geometries, tight tolerances, and zero-failure requirements.

Making the Right Choice for Your Application

Selecting the right carburizing method requires aligning the process capabilities with your specific engineering and business goals.

- If your primary focus is ultimate precision and part quality: Vacuum carburizing is the superior choice for complex geometries, such as high-performance gears, that demand exceptional uniformity and a flawless surface finish.

- If your primary focus is high throughput and process speed: The ability to use higher temperatures makes vacuum carburizing significantly faster, making it ideal for lean manufacturing environments where cycle time is critical.

- If your primary focus is cost-effectiveness for simple components: Traditional gas carburizing remains a viable and more economical option for less complex parts where the absolute precision of a vacuum process is not required.

Ultimately, understanding the unique benefits and demands of vacuum carburizing empowers you to select the most effective tool for your specific engineering challenge.

Summary Table:

| Aspect | Vacuum Carburizing | Traditional Gas Carburizing |

|---|---|---|

| Process Environment | Vacuum (oxygen-free) | Atmospheric gas |

| Surface Finish | Clean, metallic luster; no oxidation | Often requires post-cleaning due to surface oxides |

| Uniformity & Precision | Highly uniform case depth, even on complex geometries | Risk of uneven hardening on complex parts |

| Process Speed | Faster (operates at higher temperatures) | Slower due to temperature and oxidation limitations |

| Environmental Impact | Clean, self-contained; no harmful emissions | Potential for atmospheric byproducts |

| Best For | High-performance gears, aerospace components, medical devices | Simpler parts where ultimate precision is not critical |

Ready to enhance your component performance with vacuum carburizing?

At KINTEK, we specialize in advanced lab equipment and thermal processing solutions. Our expertise in vacuum furnace technology ensures your critical components achieve superior hardness, uniformity, and surface quality. Whether you're in aerospace, automotive, or medical device manufacturing, KINTEK provides the precision equipment and consumables you need for reliable, high-performance results.

Contact our experts today to discuss how our vacuum carburizing solutions can optimize your production process and meet your toughest engineering challenges.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the five basic heat treatment processes of metals? Master Annealing, Hardening & More

- What is a vacuum heat treatment furnace? The Ultimate Guide to Controlled Atmosphere Processing

- What is the difference between annealing hardening and tempering? Master Metal Properties for Your Lab

- Why do you heat treat in a vacuum? Achieve Perfect Surface Finish and Material Integrity

- What are the three main heat treatments? Mastering Annealing, Hardening & Tempering