Vacuum hardness is not a distinct material property but rather a term describing the enhanced hardness achieved in materials processed within a vacuum. It refers to the superior outcome of manufacturing methods like vacuum sintering or vacuum heat treating, where the environment itself is the key factor in achieving a harder, purer final product.

The core concept is that a vacuum is not a hardening agent, but an ideal environment. By removing atmospheric gases like oxygen, a vacuum prevents contamination and promotes better material bonding, leading to a denser and structurally superior material that is, as a result, significantly harder.

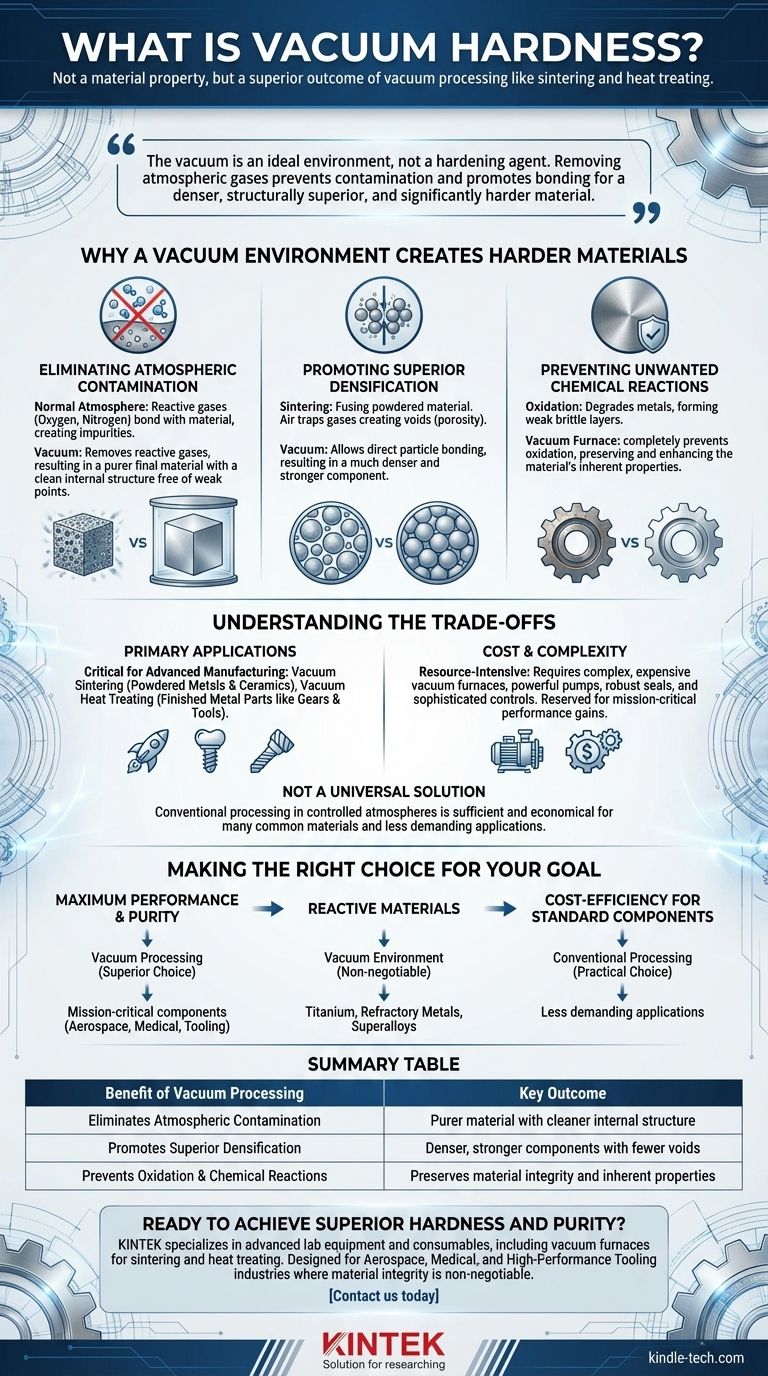

Why a Vacuum Environment Creates Harder Materials

The benefits of processing materials in a vacuum are not magical; they are rooted in fundamental physics and chemistry. The absence of air prevents a series of destructive reactions and physical impediments that would otherwise compromise the material's integrity.

Eliminating Atmospheric Contamination

In a normal atmosphere, gases like oxygen and nitrogen are highly reactive at the high temperatures used in manufacturing. These gases can bond with the material, creating impurities.

A vacuum removes these reactive gases. This results in a purer final material with a cleaner internal structure, free from the weak points that impurities would introduce.

Promoting Superior Densification

Sintering is the process of fusing powdered material into a solid mass using heat. If air is present, gases can become trapped between the material particles.

These trapped gas pockets create voids, or porosity, in the final product, which is a significant source of weakness. A vacuum allows these particles to bond directly and more completely, resulting in a much denser and stronger component.

Preventing Unwanted Chemical Reactions

Oxidation is a common reaction that can degrade metals, especially at high temperatures. This can form a weak, brittle oxide layer on the surface or even within the material's structure.

By removing the oxygen, a vacuum furnace completely prevents oxidation. This ensures the material's inherent properties are preserved and enhanced, rather than compromised by surface-level degradation.

Understanding the Trade-offs

While vacuum processing delivers superior results, it is a specialized and resource-intensive method. It is crucial to understand its context and limitations to know when its benefits justify the investment.

The Primary Applications

Vacuum processing is most critical for advanced manufacturing techniques. It is a cornerstone of vacuum sintering, used for powdered metals and ceramics, and vacuum heat treating, used to alter the properties of finished metal parts like gears and tools.

The Cost and Complexity Factor

Vacuum furnaces and their associated systems are significantly more complex and expensive to operate than conventional atmospheric furnaces. They require powerful pumps, robust seals, and sophisticated control systems.

This high cost means the process is typically reserved for applications where the performance gains—like extreme hardness, purity, and reliability—are absolutely critical.

Not a Universal Solution

For many common materials and applications, conventional processing in a controlled atmosphere is perfectly sufficient and far more economical. The decision to use a vacuum environment is driven by the material's sensitivity to contamination and the performance demands of the final product.

Making the Right Choice for Your Goal

Ultimately, specifying a vacuum process is about matching the tool to the task. Understanding the underlying goal of your project is key to making an informed decision.

- If your primary focus is maximum performance and purity: Vacuum processing is the superior choice for mission-critical components in aerospace, medical, or high-performance tooling where failure is not an option.

- If your primary focus is working with reactive materials: For metals like titanium, refractory metals, or certain superalloys that readily react with air, a vacuum environment is non-negotiable for success.

- If your primary focus is cost-efficiency for standard components: Conventional atmospheric heat treating or sintering is often the more practical and economical choice for less demanding applications.

By understanding that "vacuum hardness" is the result of a better process, you can make more precise and effective decisions for your engineering goals.

Summary Table:

| Benefit of Vacuum Processing | Key Outcome |

|---|---|

| Eliminates Atmospheric Contamination | Purer material with cleaner internal structure |

| Promotes Superior Densification | Denser, stronger components with fewer voids |

| Prevents Oxidation & Chemical Reactions | Preserves material integrity and inherent properties |

Ready to achieve superior hardness and purity for your mission-critical components?

At KINTEK, we specialize in advanced lab equipment and consumables, including vacuum furnaces for sintering and heat treating. Our solutions are designed for aerospace, medical, and high-performance tooling industries where material integrity is non-negotiable.

Contact us today to discuss how our vacuum processing expertise can enhance your material performance and reliability.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the maximum temperature in a vacuum furnace? It Depends on Your Materials and Process Needs

- What materials are used in a vacuum furnace? Selecting the Right Hot Zone for Your Process

- Can I vacuum the inside of my furnace? A Guide to Safe DIY Cleaning vs. Professional Service

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- How to vacuum out a furnace? A Step-by-Step Guide to Safe DIY Maintenance