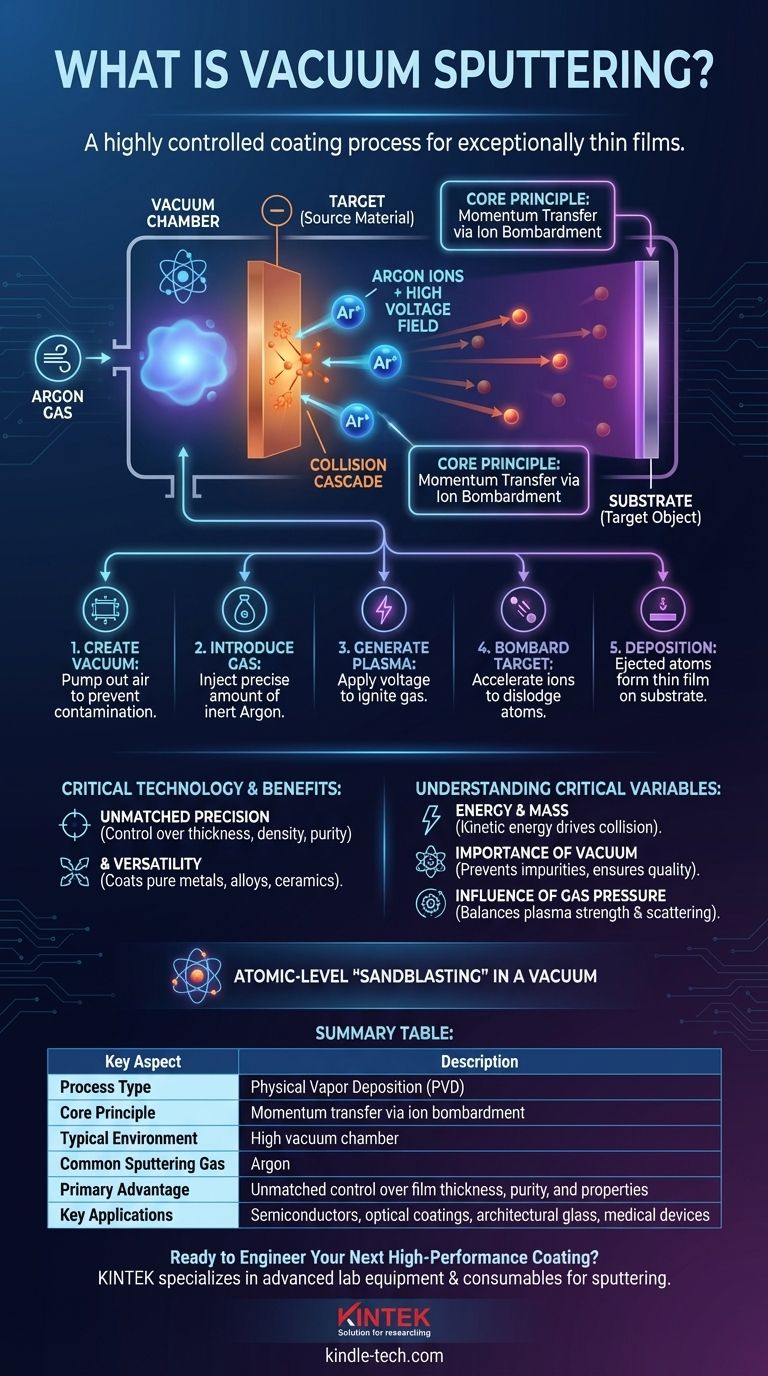

At its core, vacuum sputtering is a highly controlled coating process used to deposit exceptionally thin films of material onto a surface. It works by ejecting atoms from a source material (the "target") by bombarding it with energetic ions inside a vacuum chamber. These ejected atoms then travel and land on a second surface (the "substrate"), gradually building a uniform, high-purity layer.

Sputtering is best understood as a form of atomic-level "sandblasting" in a vacuum. Instead of sand, it uses ionized gas to chip atoms off a source material, which then reassemble into a high-performance thin film on a target object. This method gives engineers precise control over a film's thickness, density, and electrical or optical properties.

The Fundamental Principle: Momentum Transfer

Sputtering is a type of Physical Vapor Deposition (PVD), meaning it physically transfers material from a solid source into a vapor that condenses on a substrate. The entire process hinges on the physical principle of momentum transfer.

From Gas to Plasma

The process begins by creating a near-vacuum and then introducing a small amount of an inert gas, almost always Argon. A strong electric field is applied, which strips electrons from the Argon atoms.

This creates a plasma, an energized state of matter consisting of positively charged Argon ions and free electrons.

The Collision Cascade

A negative voltage is applied to the target material, causing the positive Argon ions in the plasma to accelerate and slam into it at high velocity. This impact sets off a chain reaction, or a "collision cascade," within the target's atomic structure.

When this cascade of energy reaches the target's surface, it has enough force to overcome the bonds holding the surface atoms in place, physically knocking them loose. These ejected atoms are what will form the final coating.

A Step-by-Step Breakdown of the Process

To understand sputtering in practice, it's helpful to visualize it as a sequence of discrete events occurring within a sealed chamber.

Step 1: Creating the Vacuum

The substrate and the target material are placed inside a sealed chamber. Almost all the air is pumped out to create a vacuum. This is critical to prevent the sputtered atoms from colliding with air molecules, which would contaminate the film.

Step 2: Introducing the Sputtering Gas

A small, precisely controlled amount of inert gas, typically Argon, is introduced into the chamber. The pressure is still very low, far below normal atmospheric pressure.

Step 3: Generating the Plasma

A high voltage is applied between the target (which acts as the cathode) and the chamber walls or a dedicated anode. This voltage ignites the Argon gas, transforming it into a glowing plasma.

Step 4: Bombarding the Target

The positively charged Argon ions are drawn with immense force towards the negatively charged target. They collide with the target surface, dislodging atoms or molecules of the target material.

Step 5: Deposition on the Substrate

The ejected target atoms travel through the vacuum chamber and land on the substrate. Over time, these atoms build up, nucleate, and grow into a dense, uniform, and ultra-thin film.

Why Sputtering is a Critical Technology

Sputtering is not just a laboratory curiosity; it's a foundational manufacturing technique for many modern technologies, from semiconductors to architectural glass.

Unmatched Precision and Control

The primary advantage of sputtering is control. By carefully managing the gas pressure, voltage, and time, engineers can precisely determine the thickness, density, grain structure, and purity of the resulting film.

Versatility in Materials

Sputtering can be used to deposit a vast range of materials, including pure metals, alloys, and even insulating ceramic compounds. This makes it invaluable for creating multi-layered coatings with specific optical or electrical properties.

Understanding the Critical Variables

The quality and efficiency of the sputtering process are not automatic. They depend on the careful balance of several interconnected factors.

The Role of Energy and Mass

The effectiveness of the sputtering process is a function of kinetic energy. The mass of the sputtering gas ions and their acceleration voltage directly impact how many target atoms are ejected per collision.

The Importance of the Vacuum

A poor vacuum is the most common source of failure. Any residual gas molecules, like oxygen or water vapor, will get incorporated into the growing film, creating impurities that degrade its performance.

The Influence of Gas Pressure

The pressure of the sputtering gas is a trade-off. Too little pressure means a weak plasma and a slow deposition rate. Too much pressure causes the sputtered atoms to collide with gas atoms, scattering them and reducing the quality and uniformity of the film.

How to Apply This to Your Project

Your choice of deposition parameters will be dictated entirely by the desired outcome for your thin film.

- If your primary focus is creating a high-purity film for electronics: Prioritize achieving the highest possible vacuum level and use ultra-pure sputtering gas.

- If your primary focus is coating a complex 3D shape uniformly: You will need to carefully manage gas pressure and substrate positioning to ensure even coverage.

- If your primary focus is depositing a complex alloy: Sputtering is ideal, as it generally preserves the composition of the target material in the final film.

Ultimately, vacuum sputtering provides an unparalleled ability to engineer materials at the atomic scale, building high-value surfaces layer by layer.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Principle | Momentum transfer via ion bombardment |

| Typical Environment | High vacuum chamber |

| Common Sputtering Gas | Argon |

| Primary Advantage | Unmatched control over film thickness, purity, and properties |

| Key Applications | Semiconductors, optical coatings, architectural glass, medical devices |

Ready to Engineer Your Next High-Performance Coating?

KINTEK specializes in providing the advanced lab equipment and consumables needed for precise vacuum sputtering processes. Whether you are developing next-generation semiconductors, durable optical coatings, or complex multi-layered materials, our expertise and products support your innovation from R&D to production.

Contact our experts today to discuss how we can help you achieve superior thin-film results.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Evaporation Boat for Organic Matter

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

People Also Ask

- What is the application and principle of centrifugation? Mastering Sample Separation for Your Lab

- How is a vacuum drying oven utilized in the study of sludge? Preserving Integrity for Precision Analysis

- What role does surface activation equipment play in coal gangue processing? Transform Waste into High-Value Resources

- What are the various sintering processes? A Guide to Solid vs. Liquid Phase & Pressure Techniques

- What are some of the applications of FTIR? Identify Materials from Pharma to Forensics

- What is physical vapor phase deposition? Achieve Superior Thin-Film Coatings for Your Components

- Why is it necessary to dry or calcine catalysts? Ensure Reactor Safety and Peak Performance

- How does a Hot Isostatic Press (HIP) facilitate the transformation of CVD-ZnS? From Standard to Multispectral Grade