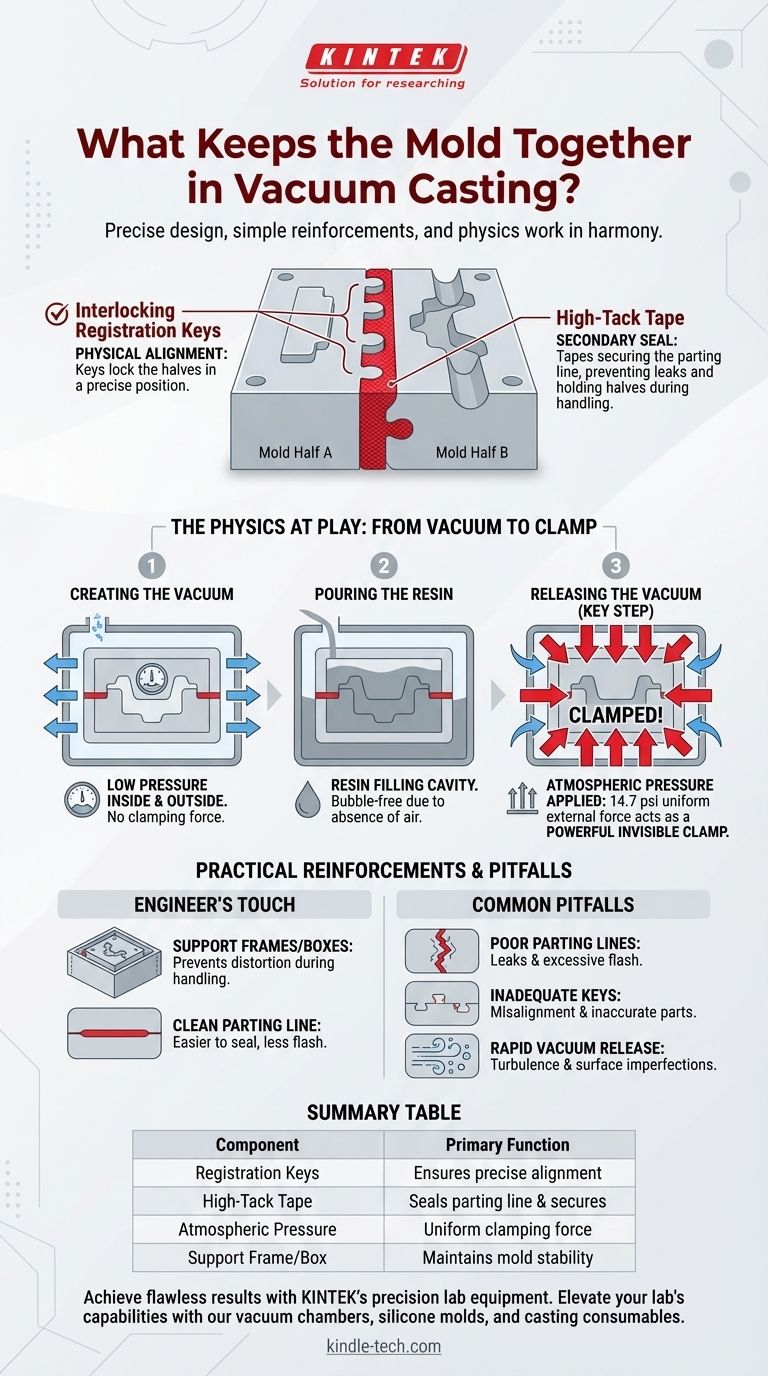

In vacuum casting, a combination of precise mold design, simple reinforcements, and fundamental physics keeps the mold halves securely together. The primary elements are interlocking registration keys built into the silicone mold, high-tack tape applied along the parting line, and the powerful, uniform force of atmospheric pressure that acts as an invisible clamp once the vacuum is released.

The core principle is straightforward: while interlocking keys provide initial alignment and tape secures the seam, it is the reintroduction of atmospheric pressure after pouring that provides the primary clamping force, pressing the mold halves together to ensure a flawless cast.

The Anatomy of a Secure Mold

Before examining the forces at play, it's crucial to understand how the silicone mold itself is designed for stability. A well-made mold is the foundation of the entire process.

The Silicone Material

Silicone is the material of choice for its flexibility, which allows for the casting of complex geometries and undercuts. However, it is also firm enough to hold its shape under the weight of the casting resin.

The Parting Line

This is the seam where the two halves of the mold meet. Its design is critical. A clean, simple parting line is easier to seal and produces less "flash"—the thin, unwanted excess material that can leak out of the seam.

Interlocking Registration Keys

This is the most critical design feature for mold alignment. The mold halves are created with matching keys—a series of bumps on one side and corresponding indentations on the other. These keys physically lock the two halves into a precise, repeatable position, preventing any sliding or shifting.

The Physics at Play: From Vacuum to Clamp

The "vacuum" in vacuum casting is often misunderstood. Its primary purpose is to remove air, but its release is what generates the clamping force.

Step 1: Creating the Vacuum

The assembled silicone mold is placed inside a chamber, and a vacuum pump removes the air from both the chamber and the mold cavity itself. At this stage, there is nearly equal low pressure inside and outside the mold, so there is no significant force trying to push it apart.

Step 2: Pouring the Resin

While under vacuum, the two-part casting resin is mixed and poured into the mold. The absence of air ensures the resin fills every tiny detail of the cavity without creating bubbles, which would be a critical defect in the final part.

Step 3: Releasing the Vacuum

This is the key step. Once the mold is full, air is allowed back into the chamber. The returning air instantly creates atmospheric pressure (approximately 14.7 psi or 1 bar at sea level) on the outside of the mold. Because the inside is filled with liquid resin, this external pressure acts as a powerful and perfectly uniform clamp, pressing the mold halves together tightly from all directions.

Practical Reinforcements: The Engineer's Touch

While physics provides the main clamping force, technicians rely on simple, practical measures to guarantee a perfect seal and prevent handling errors.

The Role of High-Tack Tape

Before the mold is placed in the chamber, its parting line is almost always sealed with a strong adhesive tape. This serves two purposes: it holds the halves together during handling and provides a crucial secondary seal to prevent any resin from leaking out before the atmospheric pressure takes over.

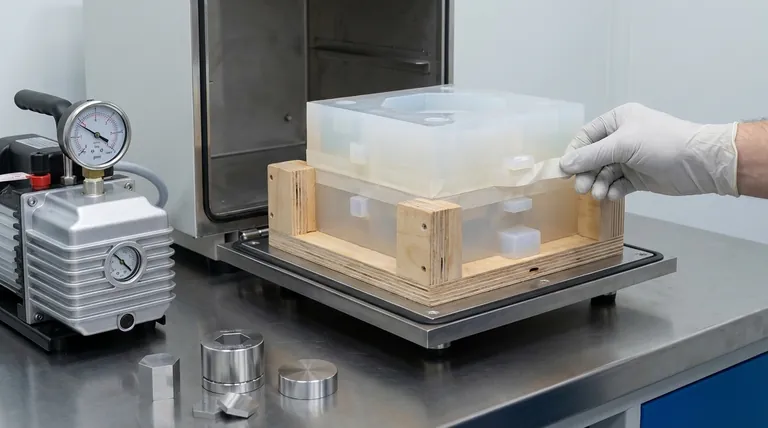

Using Support Frames or Boxes

A flexible silicone mold can be distorted if handled improperly. To prevent this, the mold is often placed inside a simple plywood or plastic box. This support frame ensures the mold remains square and stable during the pouring and curing process.

Common Pitfalls to Avoid

Understanding what holds the mold together also illuminates common failure points. A compromised seal or alignment leads directly to rejected parts.

Poorly Designed Parting Lines

A complex, jagged parting line is difficult to tape securely and is prone to leaking, resulting in excessive flash that requires manual cleanup.

Inadequate Registration Keys

If the registration keys are too small, too few, or poorly designed, the mold halves can misalign. This is a critical failure that results in a dimensionally inaccurate part.

Releasing the Vacuum Too Quickly

Allowing air to rush back into the chamber too rapidly can create turbulence. This can disturb the resin in the mold before it has time to settle, potentially introducing surface imperfections.

Making the Right Choice for Your Goal

The stability of your mold is a direct result of thoughtful design and correct procedure.

- If your primary focus is part accuracy: The design and implementation of your registration keys is the single most important factor.

- If your primary focus is preventing leaks and flash: A well-planned, simple parting line combined with careful and thorough taping is essential.

- If you are new to the process: Always use a simple support box to handle the mold, as this removes the risk of flexing it by hand and compromising the seal.

Ultimately, a successful vacuum cast relies on a mold designed to work in harmony with atmospheric pressure, not against it.

Summary Table:

| Component | Primary Function |

|---|---|

| Registration Keys | Ensures precise alignment of mold halves, preventing shifting. |

| High-Tack Tape | Seals the parting line and secures halves during handling. |

| Atmospheric Pressure | Acts as a uniform clamping force after vacuum release. |

| Support Frame/Box | Maintains mold stability and shape during pouring and curing. |

Achieve flawless vacuum casting results with KINTEK's precision lab equipment. Our vacuum chambers, silicone molds, and casting consumables are engineered to work in harmony with atmospheric pressure, ensuring your molds stay perfectly sealed for high-accuracy, bubble-free parts. Whether you're prototyping or in production, KINTEK provides the reliable tools and expertise to elevate your lab's capabilities. Contact us today to discuss your specific needs and discover the right solution for your projects!

Visual Guide

Related Products

- Polygon Press Mold for Lab

- Special Shape Press Mold for Lab

- Ball Press Mold for Lab

- Cylindrical Press Mold with Scale for Lab

- Assemble Lab Cylindrical Press Mold

People Also Ask

- How do custom graphite molds contribute to Al-20% Si/graphite flake composites? Optimize Microstructure & Conductivity

- What are the advantages of using high-strength graphite molds in the hot press sintering of Ti6Al4V-based composites?

- Is it fitting the mould or mold? A Guide to Correct Spelling by Region

- What is the core function of high-strength graphite molds? Master Vacuum Hot Press Sintering Efficiency

- Why are custom pressure molds used during the hot pressing process for solid polymer electrolytes?