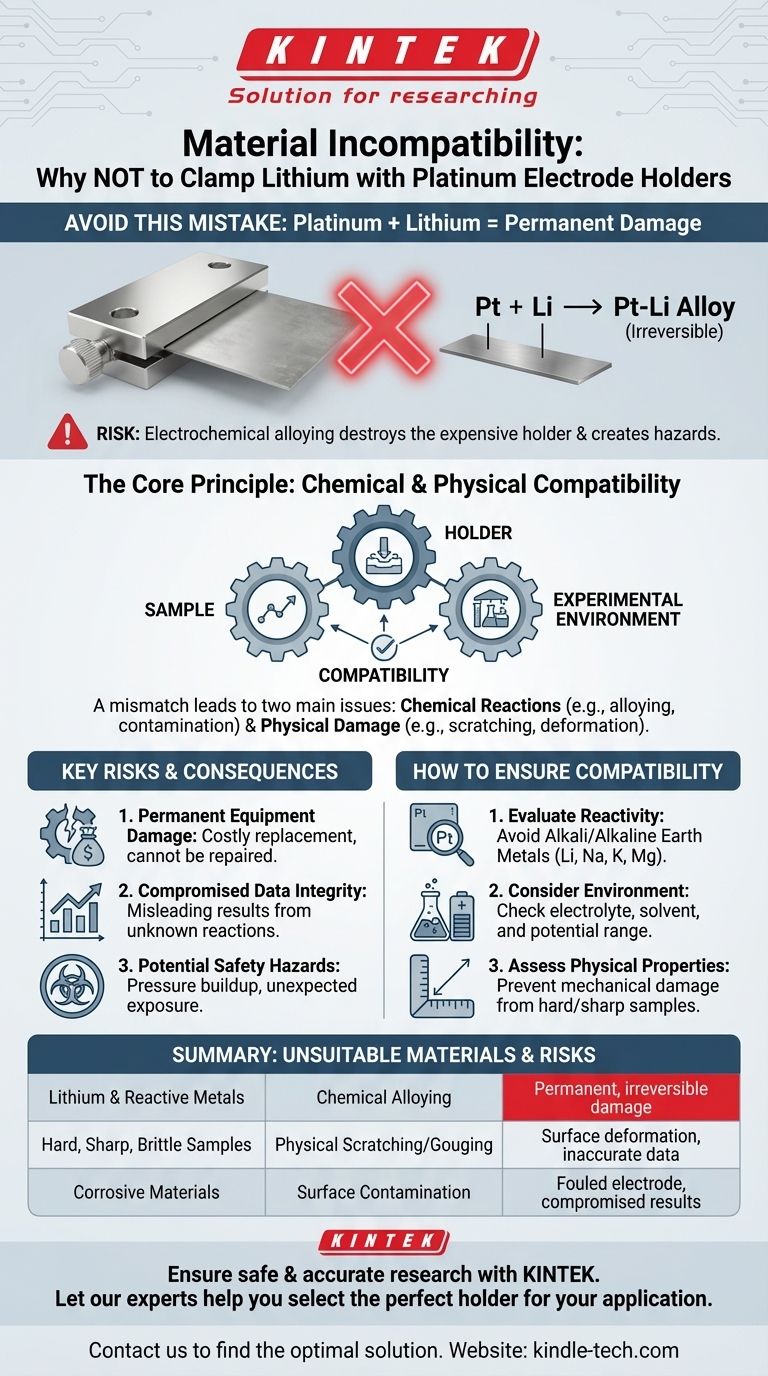

Specifically, you must not clamp highly reactive metals like lithium sheets with a platinum sheet electrode holder. This pairing is unsuitable because the materials can react, particularly under electrochemical conditions, leading to the formation of a platinum-lithium alloy. This reaction permanently damages the expensive platinum holder and can create hazardous conditions in your experiment.

The central issue extends beyond a single material. Choosing the correct sample for an electrode holder requires you to consider the chemical and physical compatibility of three components: the sample, the holder, and the experimental environment. A mismatch in any of these can lead to equipment damage, compromised data, or safety risks.

The Core Principle: Chemical and Physical Incompatibility

The fundamental reason certain materials are unsuitable for a specific holder is the risk of an unintended interaction. With a precision tool like a platinum electrode holder, these interactions fall into two main categories: chemical reactions and physical damage.

The Problem with Reactive Metals

Highly reactive metals, with lithium being a prime example, pose the most significant chemical risk to a platinum holder.

These metals have a strong tendency to lose electrons and react with other elements. When clamped by platinum, especially within an electrochemical cell, they can form intermetallic compounds or alloys. This alloying process is often irreversible and fundamentally alters the surface of the platinum, destroying its function as a pure, catalytic electrode.

Risk of Surface Contamination

Even if a material does not form a destructive alloy with platinum, it may not be inert within your experimental environment.

The sample material could slowly corrode or react with the electrolyte. The byproducts of this reaction can then deposit onto the platinum surface. This contamination fouls the electrode, blocking active sites and invalidating any electrochemical measurements.

The Impact of Physical Mismatches

Platinum is a relatively soft metal. This is a critical physical property that must be respected.

Clamping materials that are very hard, sharp, or brittle can easily scratch, gouge, or deform the delicate surface of the holder. Such mechanical damage creates non-uniformities on the electrode surface, which can disrupt electrochemical behavior and lead to inaccurate and irreproducible results.

Understanding the Inherent Risks

Using an incompatible material is not a minor error; it has significant consequences that go beyond a single failed experiment. Understanding these risks is key to developing good laboratory practice.

Permanent Equipment Damage

Platinum electrode holders are precision instruments and represent a significant financial investment. Alloying reactions cause permanent damage that cannot be polished or cleaned away. A single mistake with an unsuitable material like lithium can effectively destroy the tool, requiring a costly replacement.

Compromised Experimental Integrity

The goal of using a platinum electrode is to study a reaction on a pure, well-defined, and catalytically active surface. If the holder reacts with the sample or the sample contaminates the holder, you are no longer studying your intended system. The data you collect will be misleading, reflecting unknown side reactions rather than the process you aim to measure.

Potential Safety Hazards

The warning against "hazardous situations" is critical. A strong, uncontrolled reaction between a sample and the holder can generate significant heat or produce gas. In a sealed electrochemical cell, this can lead to a dangerous pressure buildup or an unexpected chemical exposure, posing a direct risk to the operator.

How to Ensure Material Compatibility

To avoid these issues, you must adopt a proactive approach when setting up any experiment. Your goal is to confirm that the sample material is inert relative to both the holder and the environment.

Evaluate Chemical Reactivity

Before clamping any new material, consult literature on its compatibility with platinum. Look for phase diagrams or studies on alloy formation. As a rule, avoid alkali metals (Li, Na, K), alkaline earth metals (Mg, Ca), and other highly reactive elements like aluminum or zinc, especially at reducing potentials.

Consider the Experimental Environment

A material combination that is stable in air may become highly reactive inside an electrochemical cell. Consider the electrolyte, the solvent, and the potential range you will be operating in. A seemingly stable material might corrode or dissolve under the specific conditions of your experiment.

Assess Physical Properties

Always inspect the material you intend to clamp. If it has sharp edges or is significantly harder than platinum, consider whether it can be polished or mounted differently to avoid direct, high-pressure contact that could cause mechanical damage.

Making the Right Choice for Your Experiment

Your decision should be guided by your experimental priorities.

- If your primary focus is preventing equipment damage: Be extremely conservative and never clamp a material known to be reactive with platinum, such as lithium, or any sample that is physically hard enough to scratch the holder.

- If your primary focus is data accuracy: Ensure your sample is completely inert within your chosen electrolyte and potential window to prevent any risk of surface contamination.

- If you are working with an unknown or novel material: Conduct a thorough literature review first. If uncertainty remains, consider using a less expensive and more robust holder (e.g., stainless steel, glassy carbon) for initial screening tests before risking a platinum electrode.

Ultimately, making an informed material choice is fundamental to conducting safe, repeatable, and cost-effective research.

Summary Table:

| Unsuitable Material | Primary Risk to Platinum Holder | Key Consequence |

|---|---|---|

| Lithium (and other reactive metals) | Chemical Alloying | Permanent, irreversible damage |

| Hard, Sharp, or Brittle Samples | Physical Scratching/Gouging | Surface deformation, inaccurate data |

| Materials that corrode in electrolyte | Surface Contamination | Fouled electrode, compromised results |

Ensure your experiments are safe and your data is accurate with the right equipment from KINTEK.

Choosing the correct electrode holder is critical for protecting your investment and ensuring the integrity of your research. KINTEK specializes in high-quality lab equipment and consumables, including a range of electrode holders suitable for various materials and experimental conditions.

Let our experts help you select the perfect holder for your specific application, preventing costly damage and ensuring reliable results.

Contact our team today to discuss your laboratory needs and find the optimal solution for your research.

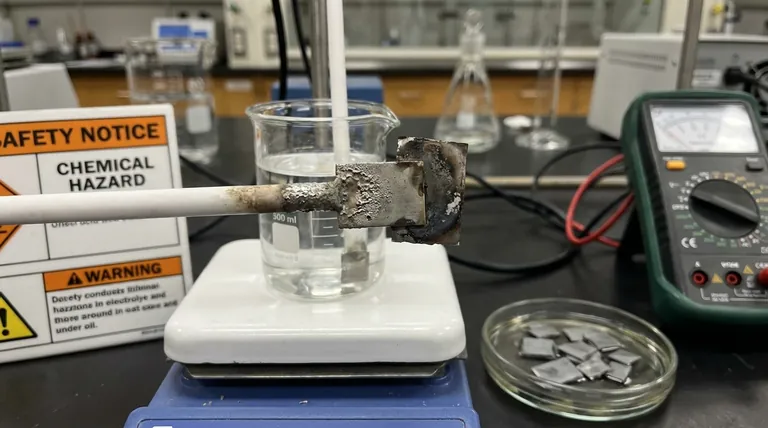

Visual Guide

Related Products

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Electrolytic Electrochemical Cell for Coating Evaluation

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- Platinum Auxiliary Electrode for Laboratory Use

People Also Ask

- What precautions should be taken when using a platinum sheet electrode? Ensure Accurate & Reproducible Electrochemical Data

- What is the expected lifespan of a platinum sheet electrode? Maximize Your Electrode's Service Life

- What is the most critical guideline for immersing a platinum sheet electrode in an electrolyte? Ensure Accurate Electrochemical Measurements

- How should a platinum sheet electrode be operated during an experiment? Ensure Accurate and Reproducible Results

- What are the performance characteristics of platinum sheet electrodes? Unlock Superior Electrochemical Performance