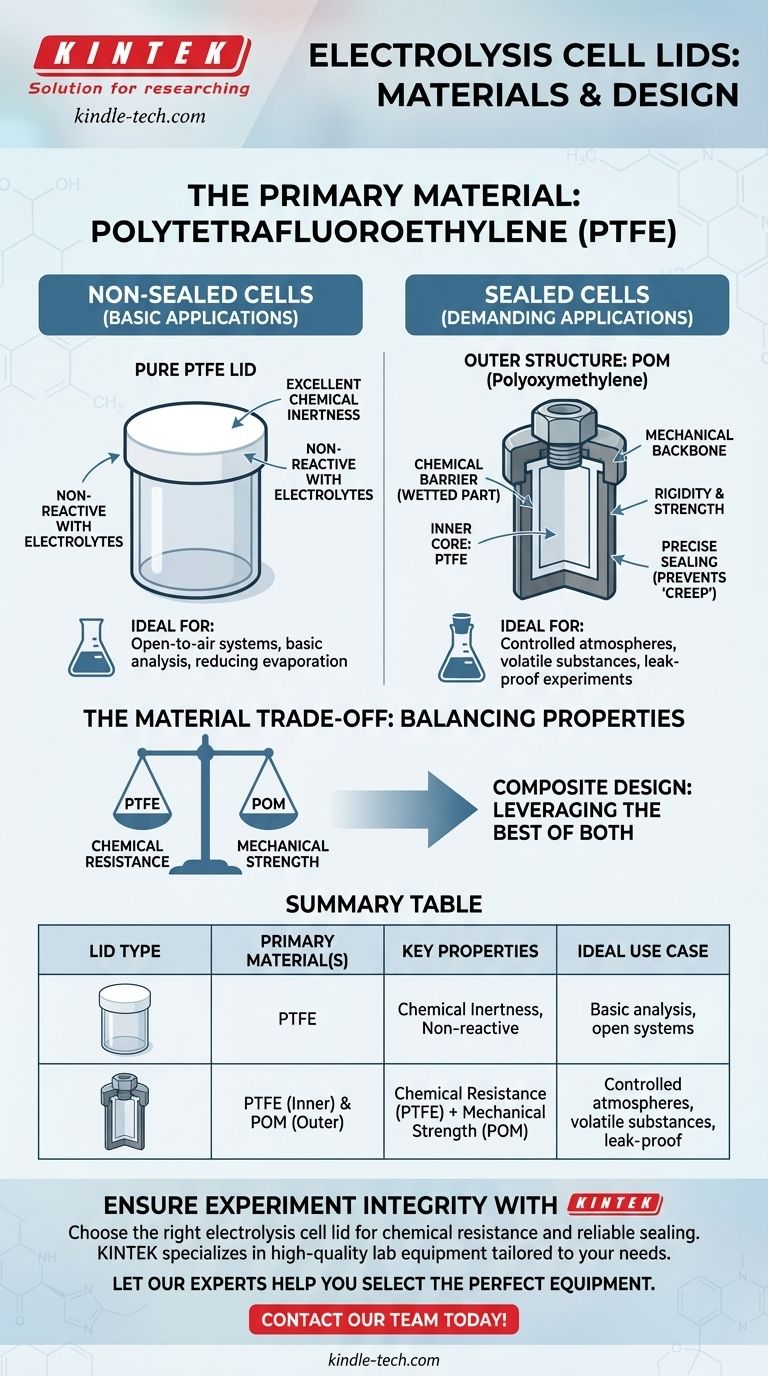

The primary material used for electrolysis cell lids is Polytetrafluoroethylene (PTFE). For simple, non-sealed cells, the lid is typically made entirely of PTFE. In more demanding sealed applications, a composite design is used, featuring a PTFE inner core for chemical resistance and a Polyoxymethylene (POM) outer structure for mechanical strength and sealing.

The choice of materials for an electrolysis cell lid is a direct function of its purpose. Chemical resistance is non-negotiable, which is why PTFE is the universal starting point. The addition of other materials like POM is purely a mechanical consideration to achieve a reliable seal.

The Core Principle: Chemical Inertness

The environment inside an electrolysis cell is often highly corrosive, involving strong acids, bases, or reactive organic solvents. The lid material must withstand this environment without degrading or contaminating the experiment.

Why PTFE is the Standard

Polytetrafluoroethylene (PTFE) is the default material for components in direct contact with the electrolyte. Its properties make it exceptionally well-suited for this role.

PTFE offers outstanding chemical resistance across a wide range of chemicals and temperatures. It is highly non-reactive, ensuring that the lid itself does not participate in or interfere with the electrochemical process.

Lids for Non-Sealed Cells

For basic, non-sealed electrolysis cells, a simple lid made entirely of PTFE is sufficient. Its function is primarily to cover the cell, reduce evaporation, and prevent contaminants from entering. In this context, the excellent chemical resistance of PTFE is the only major requirement.

Anatomy of a Sealed Cell Lid

Sealed electrolysis cells are necessary for experiments that require a controlled atmosphere, are sensitive to air or moisture, or need to contain volatile substances. This requires a more complex lid assembly capable of creating an airtight seal.

The PTFE Inner Core: The Chemical Shield

The part of the lid assembly that faces the inside of the cell—the "wetted" part—is almost always made of PTFE. This component serves as the chemical barrier, protecting the rest of the assembly from the corrosive electrolyte.

The POM Outer Structure: The Mechanical Backbone

While PTFE is chemically robust, it is a relatively soft material that can deform under pressure (a phenomenon known as "creep"). This makes it less than ideal for creating and holding the strong mechanical force needed for a reliable seal.

This is why Polyoxymethylene (POM) is used for the outer cap and nut assembly. POM is a rigid engineering plastic with excellent mechanical strength and stability. It allows for precise threads that can be tightened to apply consistent pressure, compressing the PTFE core to form a tight, leak-proof seal against the cell body.

Understanding the Trade-offs

The two-material design of a sealed lid is a classic engineering solution that balances competing requirements. No single material perfectly satisfies both chemical and mechanical needs for this application.

The Limitation of a Pure PTFE Design

A lid made entirely of PTFE would struggle to maintain a high-integrity seal over time. Applying the necessary torque to seal the cell would risk deforming or stripping the soft PTFE threads, leading to leaks and inconsistent experimental conditions.

The Strength of a Composite Solution

By combining materials, the design leverages the best properties of each. PTFE provides the essential chemical inertness where it matters most—at the interface with the electrolyte. POM provides the mechanical rigidity and strength needed to build a durable, reliable sealing structure around it.

Making the Right Choice for Your Experiment

Your choice of lid depends entirely on the requirements of your electrochemical setup.

- If your primary focus is basic electrochemical analysis in an open-to-air system: A simple, non-sealed PTFE lid offers the necessary chemical compatibility and is the most straightforward option.

- If your primary focus is controlling the cell's atmosphere, working with volatile substances, or preventing any leaks: A sealed cell with a composite PTFE/POM lid assembly is the required choice for reliable and repeatable results.

Understanding how materials are chosen to meet specific functional demands is key to selecting the correct equipment for your work.

Summary Table:

| Lid Type | Primary Material(s) | Key Properties | Ideal Use Case |

|---|---|---|---|

| Non-Sealed Cell Lid | PTFE | Excellent chemical inertness, non-reactive | Basic analysis in open-to-air systems |

| Sealed Cell Lid | PTFE (inner core) & POM (outer structure) | Chemical resistance (PTFE) + Mechanical strength/sealing (POM) | Controlled atmospheres, volatile substances, leak-proof experiments |

Ensure the integrity of your electrochemical experiments with the right lab equipment from KINTEK.

Choosing the correct electrolysis cell lid is critical for chemical resistance and reliable sealing. KINTEK specializes in high-quality lab equipment and consumables, including electrolysis cells with precisely engineered PTFE and POM lids tailored to your specific application needs—whether for basic analysis or demanding sealed environments.

Let our experts help you select the perfect equipment for reliable and repeatable results. Contact our team today to discuss your laboratory requirements!

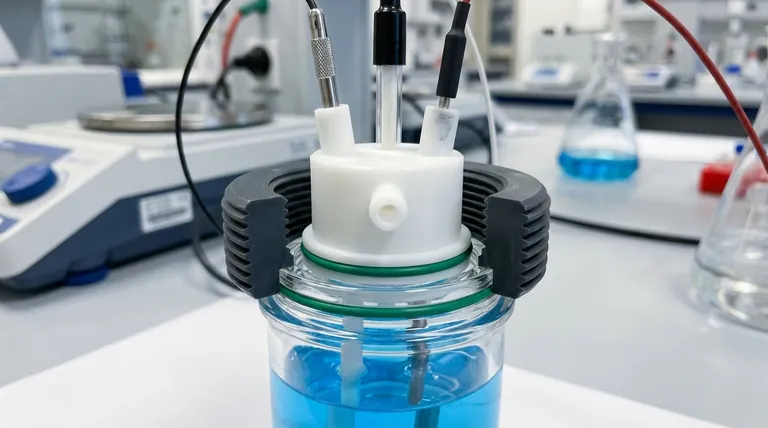

Visual Guide

Related Products

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- Electrolytic Electrochemical Cell for Coating Evaluation

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Thin-Layer Spectral Electrolysis Electrochemical Cell

People Also Ask

- What materials are used for the body of a super-sealed electrolytic cell and what are their properties? Select the Right Material for Your Experiment

- What is the proper cleaning method for an all-PTFE electrolytic cell? Essential Tips for Surface Integrity

- What are the key material properties and structural features of an all-PTFE electrolytic cell? Achieve Unmatched Purity in Harsh Electrochemical Environments

- How should an all-PTFE electrolytic cell be handled to prevent mechanical damage? Protect Your Investment and Data Integrity

- What are the standard opening specifications for all-PTFE electrolytic cells? A Guide to Sealed vs. Non-Sealed Ports