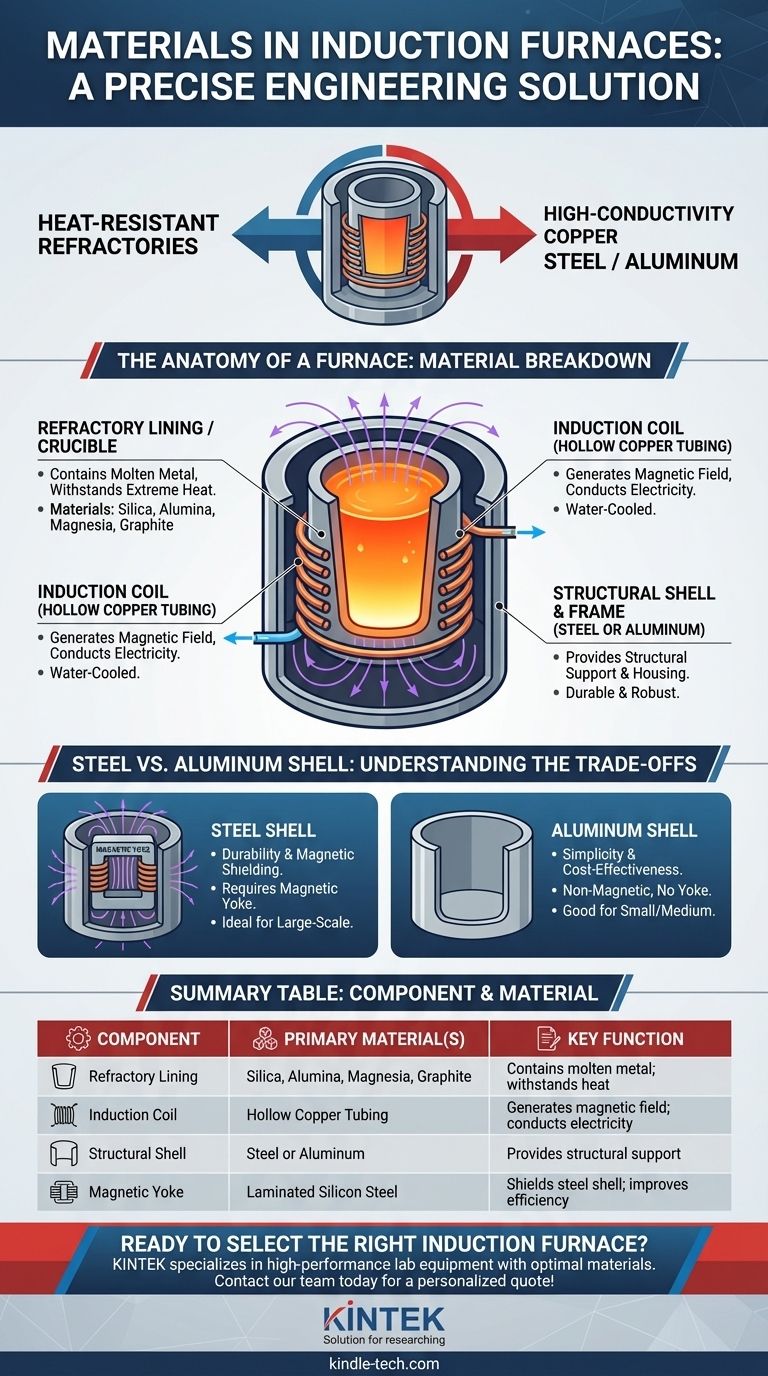

At its core, an induction furnace is constructed from three primary types of materials: heat-resistant refractories to contain the molten metal, high-conductivity copper for the induction coil, and a structural steel or aluminum shell to hold everything together. These materials are carefully selected to manage extreme temperatures, powerful magnetic fields, and immense electrical currents simultaneously.

The material composition of an induction furnace is not arbitrary; it represents a precise engineering solution. Each component's material is chosen for its specific properties—either to resist heat, conduct electricity, or provide structural support—to safely and efficiently melt metal using electromagnetic induction.

The Anatomy of a Furnace: A Material Breakdown

An induction furnace is a system of specialized components, each made from materials perfectly suited for its function. Understanding these parts reveals why the furnace is so effective.

The Core Containment: Refractory Lining and Crucible

The refractory lining is the furnace's first line of defense, a non-metallic material designed to withstand extreme temperatures without melting or reacting with the charge. It directly contains the molten metal.

This lining, often forming a crucible, is typically made from ceramic materials. The specific choice depends on the type of metal being melted (acidic vs. basic). Common refractory materials include silica, alumina, and magnesia. For some applications, graphite crucibles are also used.

The Engine: The Induction Coil

The heart of the furnace is the induction coil. This component generates the powerful, alternating magnetic field that induces heat in the metal charge.

To perform this task efficiently, the coil must be an excellent electrical conductor. It is almost always made from hollow copper tubing. The hollow design is critical, as it allows cooling water to be continuously circulated through the coil, preventing it from overheating and melting under the immense electrical load.

The Support Structure: Shell and Frame

The coil and refractory assembly are housed within a robust outer body. A heavy-duty steel frame provides the primary structural support for the coil assembly.

This entire structure is enclosed in an outer shell, which can be made of either steel or aluminum. The choice between these two metals is a key design decision with significant performance implications.

The Power and Control Systems

The furnace relies on a suite of auxiliary systems. The power supply uses transformers and inverters containing copper windings and silicon-based semiconductors. A cooling system uses pumps and hoses to circulate water, and fume extraction equipment is typically fabricated from steel ducting.

Understanding the Trade-offs: Steel Shell vs. Aluminum Shell

The choice of shell material is not just cosmetic; it directly impacts the furnace's efficiency, durability, and cost.

Steel Shell: Durability and Magnetic Shielding

A steel shell provides maximum mechanical strength and rigidity, making it suitable for very large furnaces and harsh industrial environments.

However, because steel is a magnetic material, it would be heated by the furnace's own magnetic field. To prevent this, steel shell furnaces must include a magnetic yoke (made of laminated silicon steel) between the coil and the shell. This yoke redirects the magnetic field, improving electrical efficiency and protecting the shell.

Aluminum Shell: Simplicity and Cost-Effectiveness

An aluminum shell is non-magnetic, so it does not interact with or get heated by the magnetic field. This eliminates the need for a complex and costly magnetic yoke, resulting in a simpler, lighter, and often less expensive furnace construction.

While not as mechanically robust as steel, aluminum shells are perfectly adequate for many small- to medium-sized furnace applications and offer a significant cost-to-performance advantage.

Making the Right Choice for Your Goal

The materials used in a furnace are directly tied to its intended application. Understanding your primary goal helps clarify which design features are most important.

- If your primary focus is maximum durability and large-scale production: A steel shell furnace is often the superior choice for its structural rigidity and long-term resilience in demanding environments.

- If your primary focus is cost-efficiency and operational simplicity: An aluminum shell furnace offers excellent performance for many applications without the added complexity and cost of a magnetic yoke.

- If you are melting specific or reactive metals: Your most critical material decision will be the type of refractory lining, as its chemical compatibility with the molten charge is essential for purity and safety.

By understanding how each material contributes to the furnace's function, you can make more informed decisions about equipment selection, operation, and maintenance.

Summary Table:

| Component | Primary Material(s) | Key Function |

|---|---|---|

| Refractory Lining / Crucible | Silica, Alumina, Magnesia, Graphite | Contains molten metal; withstands extreme heat |

| Induction Coil | Hollow Copper Tubing | Generates magnetic field; conducts electricity |

| Structural Shell | Steel or Aluminum | Provides structural support and housing |

| Magnetic Yoke (Steel Shell) | Laminated Silicon Steel | Shields shell; improves efficiency |

Ready to select the right induction furnace for your lab's specific needs?

KINTEK specializes in high-performance lab equipment, including induction furnaces built with the optimal materials for your applications—whether you require the durability of a steel shell or the cost-efficiency of an aluminum design. Our experts will help you choose the perfect furnace to ensure precise temperature control, operational safety, and long-lasting performance.

Contact our team today to discuss your requirements and get a personalized quote!

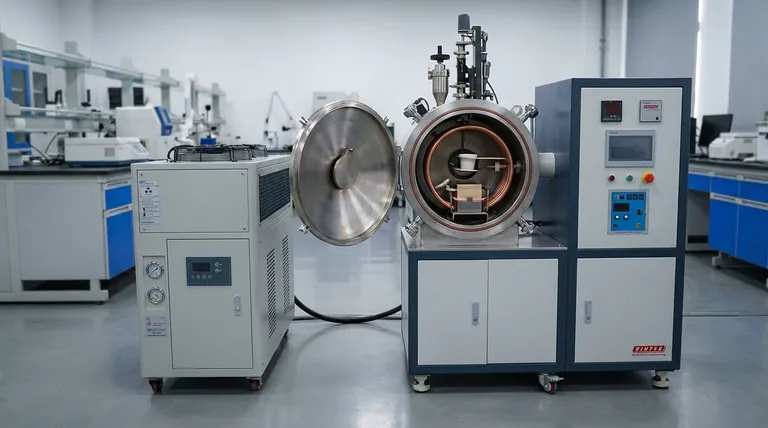

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Non Consumable Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is the power of induction furnace? Unlock Precise Control and Efficiency for Your Lab

- What is induction heating equipment? Achieve Fast, Precise, and Clean Thermal Processing

- What are the advantages of an induction furnace? Achieve Clean, Fast, and Precise Metal Melting

- What is the arc melting method? Master High-Purity Metal & Alloy Processing

- Why is high frequency used in induction furnace? For Precise, Efficient, and Clean Metal Heating

- What is the mechanism of induction furnace heating? Discover Efficient, Precise Metal Melting

- How do I control the temperature of my induction heater? Master Precise Power & Feedback Control

- What role does a vacuum induction furnace play in melting 12% Chromium steel? Ensuring Purity and Alloy Integrity