The materials used in thin-film optical coatings are primarily a select group of dielectric oxides, fluorides, and specialized compounds, along with certain metals. These materials are chosen for their specific refractive index and low optical absorption at the wavelengths of interest. Common examples include low-index materials like Silicon Dioxide (SiO₂) and Magnesium Fluoride (MgF₂), and high-index materials like Titanium Dioxide (TiO₂) and Tantalum Pentoxide (Ta₂O₅).

The performance of an optical coating is not determined by a single material, but by the precise layering of multiple materials with contrasting refractive indices. The choice of material is a strategic decision based on the desired optical function, the wavelength of operation, and required environmental durability.

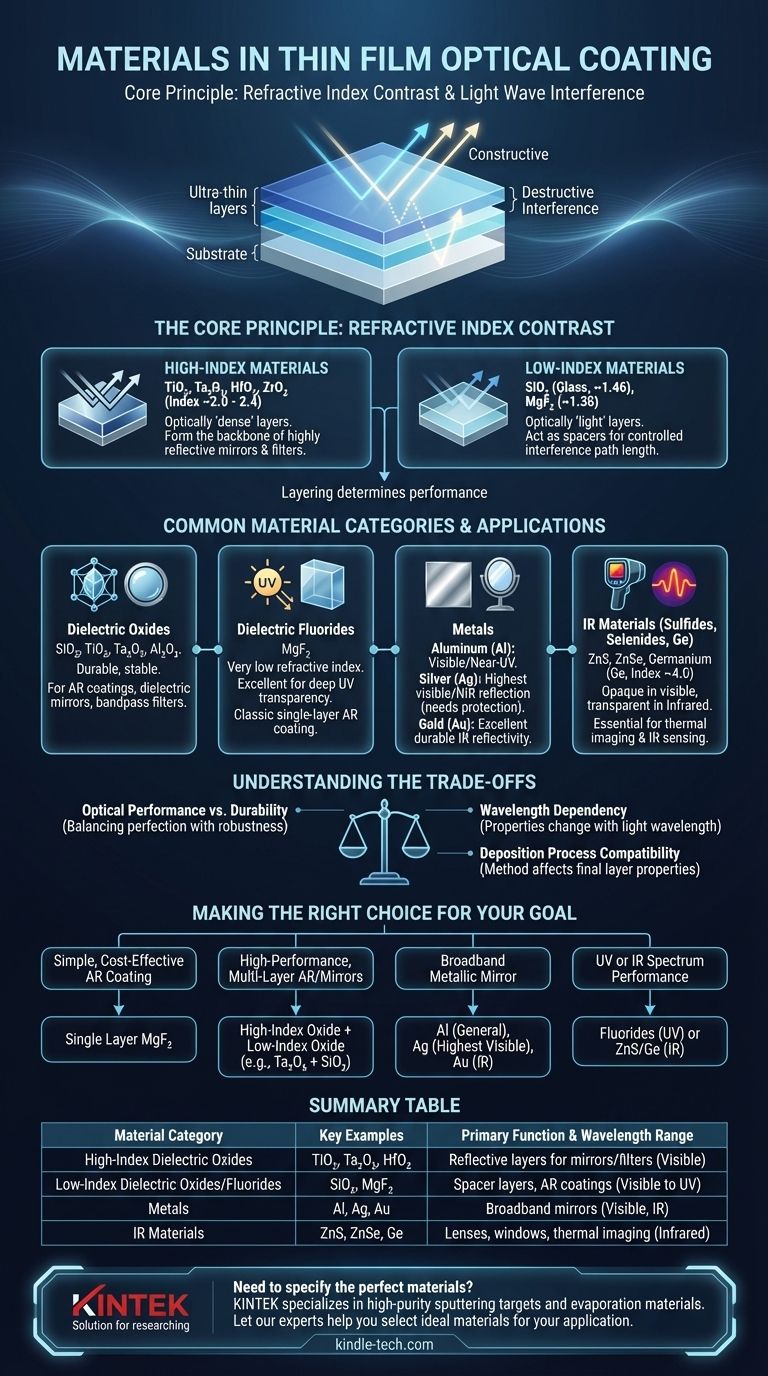

The Core Principle: Refractive Index Contrast

The function of most optical coatings is based on the principle of light wave interference. By stacking ultra-thin layers of different materials, we can control whether light waves reflecting from each interface add up (constructive interference) or cancel each other out (destructive interference).

The Role of High-Index Materials

High-index-of-refraction materials are the optically "dense" layers in a coating stack. They cause a stronger reflection at each interface, forming the backbone of highly reflective mirrors or the primary functioning layers in filters.

Common high-index materials include Titanium Dioxide (TiO₂), Tantalum Pentoxide (Ta₂O₅), Hafnium Dioxide (HfO₂), and Zirconium Dioxide (ZrO₂). Their refractive indices are typically in the range of 2.0 to 2.4 in the visible spectrum.

The Role of Low-Index Materials

Low-index-of-refraction materials are the optically "light" layers. They act as spacers, creating the precise path length difference needed for the light waves to interfere in a controlled way.

The most common low-index material is Silicon Dioxide (SiO₂), which is essentially glass. It is durable and has a refractive index of approximately 1.46. For applications requiring an even lower index, Magnesium Fluoride (MgF₂) is used, with an index of around 1.38.

Common Material Categories and Their Applications

The specific material family is chosen based on the target wavelength range and the desired physical properties of the coating.

Dielectric Oxides

These are the workhorses of the visible spectrum. Materials like SiO₂, TiO₂, Ta₂O₅, and Aluminum Oxide (Al₂O₃) are durable, environmentally stable, and deposit well using modern techniques. They are used for the vast majority of anti-reflection coatings, dielectric mirrors, and bandpass filters.

Dielectric Fluorides

Fluorides, most notably **Magnesium Fluoride (MgF₂) **, are prized for their very low refractive indices and excellent transparency deep into the ultraviolet (UV) spectrum. MgF₂ is the classic material for single-layer anti-reflection coatings on glass.

Metals

When a very broad range of reflection is needed, metals are the ideal choice. They are opaque and highly reflective.

- Aluminum (Al): The most common and cost-effective mirror coating for the visible and near-UV.

- Silver (Ag): Offers the highest reflectance in the visible and near-infrared (IR) but can tarnish if not protected by a dielectric overcoat.

- Gold (Au): Provides excellent, durable reflectivity in the IR spectrum.

Sulfides, Selenides, and Germanium

These materials are opaque in the visible spectrum but become transparent in the infrared. They are used exclusively for IR applications. Materials like Zinc Sulfide (ZnS), Zinc Selenide (ZnSe), and Germanium (Ge) (which has a very high index of ~4.0) are essential for thermal imaging and IR sensing systems.

Understanding the Trade-offs

Selecting a material is never about a single property. It is always a balance of competing requirements.

Optical Performance vs. Durability

Some materials that offer ideal optical properties may be mechanically soft or porous. A more durable material, like a hard oxide, might have higher mechanical stress, which can be a problem on certain substrates. The final choice often balances optical perfection with real-world robustness.

Wavelength Dependency

A material’s properties are not constant; they change with the wavelength of light. A coating designed for visible light will not perform as expected in the UV or IR because the refractive index and absorption of its constituent materials will be different.

Deposition Process Compatibility

The method used to create the thin film (e.g., evaporation, sputtering) has a significant impact on the final properties of the material layer. The choice of material must be compatible with a deposition process that produces dense, stable, and uniform layers.

Making the Right Choice for Your Goal

The ideal material combination is dictated entirely by your application's specific requirements.

- If your primary focus is a simple, cost-effective anti-reflection coating: A single layer of Magnesium Fluoride (MgF₂) is the classic solution.

- If your primary focus is high-performance, multi-layer anti-reflection or dielectric mirrors: You will need a combination of a high-index oxide (like Tantalum Pentoxide, Ta₂O₅) and a low-index oxide (Silicon Dioxide, SiO₂).

- If your primary focus is a broadband metallic mirror: Aluminum (Al) is the standard for general use, while protected Silver (Ag) is for highest visible reflectance, and Gold (Au) is for the infrared.

- If your primary focus is performance in the ultraviolet (UV) or infrared (IR) spectrums: You must select specialized materials like fluorides for UV or compounds like Zinc Sulfide (ZnS) and Germanium (Ge) for IR applications.

Ultimately, material selection is a foundational step in designing an optical coating that successfully manipulates light to achieve a specific outcome.

Summary Table:

| Material Category | Key Examples | Primary Function & Wavelength Range |

|---|---|---|

| High-Index Dielectric Oxides | TiO₂, Ta₂O₅, HfO₂ | Highly reflective layers for mirrors/filters (Visible spectrum) |

| Low-Index Dielectric Oxides/Fluorides | SiO₂, MgF₂ | Spacer layers for interference; AR coatings (Visible to UV) |

| Metals | Aluminum (Al), Silver (Ag), Gold (Au) | Broadband mirrors (Visible, IR) |

| IR Materials | ZnS, ZnSe, Germanium (Ge) | Lenses, windows, coatings for thermal imaging (Infrared) |

Need to specify the perfect materials for your optical coating application?

The choice of materials is critical to the performance, durability, and cost of your optical components. KINTEK specializes in providing high-purity materials and expert support for your thin-film deposition processes. We supply a wide range of sputtering targets and evaporation materials, including the precise oxides, fluorides, and metals discussed here.

Let our experts help you select the ideal materials for your specific wavelength and performance requirements.

Contact our team today to discuss your project and ensure optimal results.

Visual Guide

Related Products

- Optical Ultra-Clear Glass Sheet for Laboratory K9 B270 BK7

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Aluminum-Plastic Flexible Packaging Film for Lithium Battery Packaging

- High Purity Zinc Foil for Battery Lab Applications

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the advantages of thin film substrate? Enhance Surface Functionality for Superior Products

- What is the difference between metallic and non-metallic coating? A Guide to Sacrificial vs. Barrier Protection

- What is the process of sputtering chemically? Master Reactive Sputtering for Superior Thin Films

- What makes nanotubes special? Discover the Revolutionary Material Combining Strength, Conductivity & Lightness

- How are sputtering targets made? From Ultra-Pure Materials to High-Performance Thin Films

- What are carbon nanotubes explain its types? Unlocking the Power of SWCNTs and MWCNTs

- What materials are CVD deposition? From Semiconductors to Super-Hard Coatings

- Why carbon nanotubes are better than graphene? Matching Material Geometry to Your Engineering Challenge