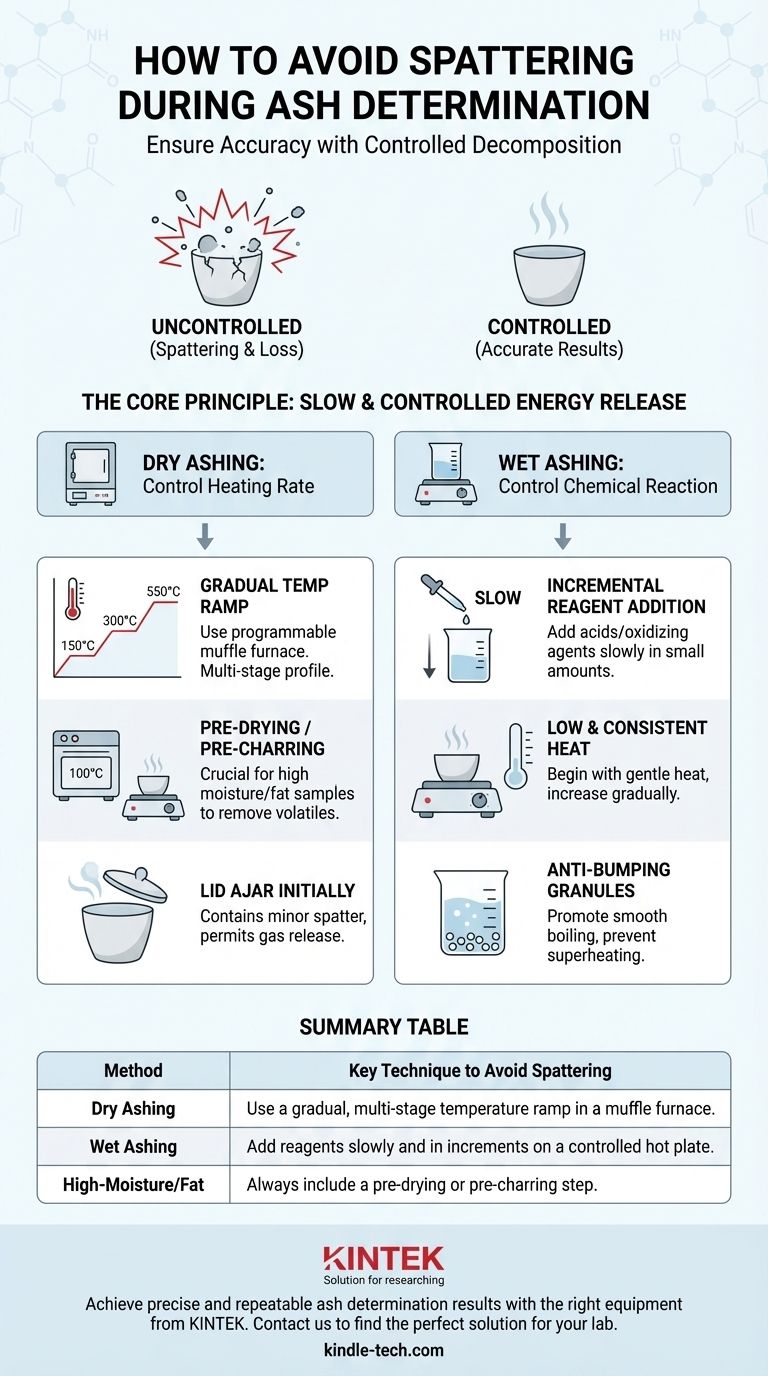

To prevent spattering during ash determination, the fundamental strategy is to ensure a slow and controlled decomposition of the organic material. This is achieved by either gradually increasing the temperature during dry ashing or by carefully managing the rate of chemical reaction during wet ashing. Spattering, which is the forceful ejection of sample particles from the crucible, leads directly to sample loss and inaccurate, unreliable results.

The core reason for spattering during ash analysis is an uncontrolled release of energy, either thermal or chemical. The universal solution is to apply that energy slowly and methodically, allowing volatile compounds and gases to escape gently rather than explosively.

Understanding the Root Cause of Spattering

Before implementing a solution, it's critical to understand why spattering occurs. The phenomenon is almost always traced back to one of two primary causes, depending on the ashing method used.

Trapped Moisture and Volatiles

In dry ashing, the sample is heated to very high temperatures (typically 500-600°C) in a muffle furnace. If this heating is too rapid, any trapped moisture or volatile organic compounds (like fats or oils) will vaporize quickly.

This rapid conversion to gas creates a sudden pressure buildup within the sample matrix, leading to "micro-explosions" that eject solid particles from the crucible.

Vigorous Chemical Reactions

In wet ashing (also known as wet digestion), strong acids and oxidizing agents are used to break down the organic matter at much lower temperatures.

If these powerful reagents are added too quickly or the sample is heated too aggressively, the resulting exothermic reaction can become uncontrollably vigorous. This causes violent boiling and bubbling, which splashes the sample out of its container.

Spattering Control in Dry Ashing

For dry ashing, control is centered on managing the heating rate. Rushing this process is the most common mistake leading to sample loss.

Implement a Gradual Temperature Ramp

The single most effective technique is to use a programmable muffle furnace to create a slow, multi-stage heating profile. Do not place a sample directly into a pre-heated 550°C furnace.

A typical profile might involve holding the temperature at 150°C to drive off moisture, then slowly ramping to 300°C to char the organic matter, before finally ramping to the target ashing temperature. This allows gases to evolve gently.

The Importance of a Pre-Drying or Pre-Charring Step

For samples with high moisture or fat content, a preliminary step is crucial. Pre-drying the sample in an oven at a low temperature (around 100°C) removes most of the water.

Alternatively, carefully pre-charring the sample over a Bunsen burner or on a hot plate can gently burn off the most volatile compounds before the sample is placed in the high-temperature furnace.

Use a Lid During Initial Stages

Placing a crucible lid slightly ajar during the initial heating phases can help contain any minor spatter. It is critical that the lid is not sealed, as this would trap escaping gases and could cause the lid to be blown off.

Spattering Control in Wet Ashing

For wet ashing, control is focused on managing the chemical reaction itself. The goal is a steady, gentle oxidation, not a violent one.

Careful and Incremental Reagent Addition

Never add the full volume of acid or oxidizing agent (like hydrogen peroxide) all at once. Add the reagent slowly, in small increments, allowing the initial reaction to subside before adding more.

Maintain Low and Consistent Heat

Use a laboratory hot plate with precise temperature control. Begin the digestion at a low temperature to initiate a gentle reaction. Only increase the heat gradually as the initial, most vigorous phase of the reaction subsides.

Use Anti-Bumping Granules

Adding a few boiling chips or anti-bumping granules to the digestion vessel promotes smooth, even boiling. This prevents the buildup of superheated pockets of liquid that can erupt suddenly and cause splashing.

Understanding the Trade-offs

Choosing the right approach requires balancing accuracy with efficiency. Preventing spattering is fundamentally about taking more time to achieve a better result.

Speed vs. Accuracy

A slow, multi-stage heating program or a cautious wet digestion will always take longer than a rapid, single-step process. However, the time saved by rushing is often lost when the results are inaccurate due to sample loss and the entire analysis must be repeated.

Method Selection and Sample Type

The choice between dry and wet ashing can be influenced by the sample itself. Samples known to be highly volatile or reactive (e.g., high-sugar or high-fat samples) are particularly prone to spattering in dry ashing. For these, a careful wet digestion might offer better control, despite being more labor-intensive.

Making the Right Choice for Your Goal

Your strategy for avoiding spattering should be dictated by your sample type and analytical requirements.

- If your primary focus is routine analysis of stable samples: A controlled, multi-stage heating program in a programmable muffle furnace (dry ashing) is both efficient and reliable.

- If your sample is high in moisture or volatile fats: Always incorporate a thorough pre-drying or gentle pre-charring step before beginning the main dry ashing temperature ramp.

- If you are analyzing for volatile minerals that could be lost at high temperatures: Choose wet ashing, but ensure you add oxidizing agents slowly and in small increments on a controlled hot plate to prevent spattering.

Ultimately, treating the initial decomposition of the sample with patience is the single most effective strategy for guaranteeing accurate and repeatable ash determination.

Summary Table:

| Method | Key Technique to Avoid Spattering |

|---|---|

| Dry Ashing | Use a gradual, multi-stage temperature ramp in a muffle furnace. |

| Wet Ashing | Add reagents slowly and in increments on a controlled hot plate. |

| For High-Moisture/Fat Samples | Always include a pre-drying or pre-charring step. |

Achieve precise and repeatable ash determination results with the right equipment from KINTEK.

Spattering leads to sample loss and inaccurate data. Our range of programmable muffle furnaces for controlled dry ashing and precise hot plates for gentle wet digestion provides the reliability your laboratory needs. We specialize in lab equipment and consumables to help you optimize your sample preparation workflows.

Contact KINTEK today to discuss your specific application and find the perfect solution for accurate ash analysis.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the principle working and use of muffle furnace? Achieve Precise, Contamination-Free Heating

- What is the main purpose of a furnace? A Guide to Heating, Comfort, and Material Transformation

- What are the precautions of muffle furnace? Essential Safety Protocols for Your Lab

- What is the difference between muffle furnace and induction furnace? Choosing the Right Heat Source for Your Lab

- How to use a muffle furnace in a laboratory? A Step-by-Step Guide to Safe, Precise Thermal Processing