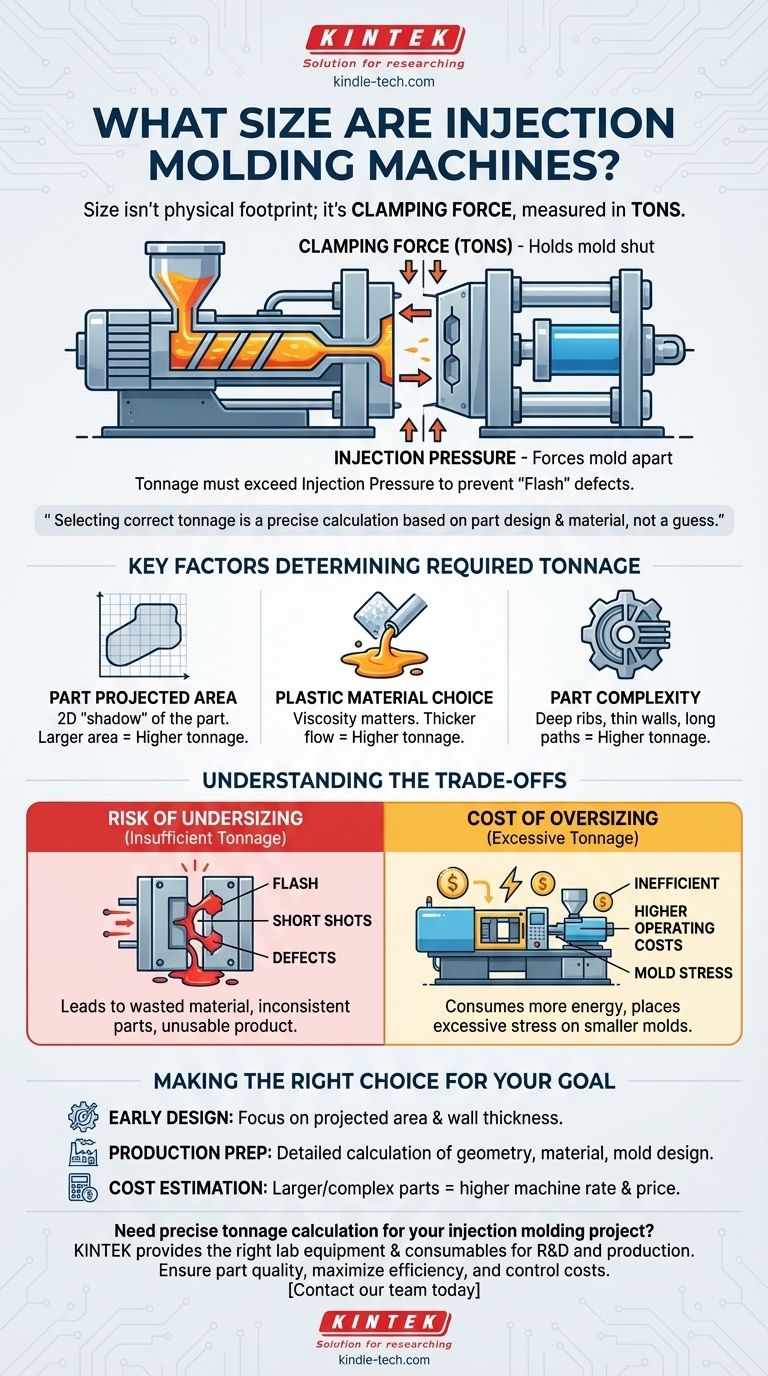

Injection molding machines range dramatically in size, from small units under 5 tons to massive industrial systems exceeding 4,000 tons. This "size" isn't about the machine's physical footprint, but its clamping force, a critical factor determined by the specific part being manufactured.

The most important concept to understand is that machine "size" refers to its clamping force, measured in tons. Selecting the correct tonnage is a precise calculation based on your part's design and material, not a rough estimate.

What "Machine Size" Actually Means

The tonnage rating is the single most important specification of an injection molding machine. It defines the machine's capability and suitability for a given project.

The Critical Role of Tonnage

A machine's size is defined by the tonnage of its clamping force. This is the amount of force the machine can exert to hold the two halves of a mold securely closed during the injection process.

Understanding Clamping Force

When molten plastic is injected into the mold cavity, it exerts a tremendous amount of pressure, trying to force the mold halves apart. The clamping unit must generate an equal or greater opposing force to keep the mold sealed shut.

Why It Matters

If the clamping force is too low for the injection pressure, molten plastic will leak out of the mold cavity, creating a defect known as "flash". This results in wasted material, inconsistent parts, and requires additional labor to fix.

Key Factors That Determine Required Tonnage

Choosing the correct machine size is a calculation, not a guess. Several factors directly influence the amount of clamping force your part will require.

Part Projected Area

This is the most significant factor. The projected area is the two-dimensional "shadow" your part would cast. A larger surface area creates more opposing force that the clamp must overcome.

Plastic Material Choice

Different plastics have different flow characteristics (viscosity). Materials that are thicker or flow less easily require higher injection pressures, which in turn demands a higher clamping force to keep the mold sealed.

Part Complexity

Parts with deep ribs, long flow paths, or very thin walls often require higher injection pressures to fill completely. This increased pressure must be countered by a proportional increase in clamping tonnage.

Understanding the Trade-offs

Selecting the wrong machine size—either too large or too small—has significant consequences for both quality and cost.

The Risk of Undersizing

Using a machine with insufficient tonnage is a primary cause of manufacturing defects. It leads directly to flash, incomplete parts ("short shots"), and dimensional inaccuracies, rendering the final product unusable.

The Cost of Oversizing

While it may seem safe to use a much larger machine than necessary, it is highly inefficient. Larger machines have higher operating costs, consume more energy, and can place excessive stress on smaller molds, potentially reducing their lifespan.

Making the Right Choice for Your Goal

The goal is to match the machine to the part as closely as possible to ensure quality and efficiency. This requires a specific calculation, not a general guess.

- If your primary focus is early design: Concentrate on your part's projected surface area and wall thickness, as these are the main drivers of the required machine size.

- If your primary focus is preparing for production: You must work with your manufacturing partner to perform a detailed calculation considering the part geometry, chosen material, and mold design.

- If your primary focus is cost estimation: Understand that larger, more complex parts requiring higher-tonnage machines will result in a higher per-hour machine rate and overall piece price.

Properly matching machine tonnage to your part's specific requirements is the foundation of efficient, high-quality plastic injection molding.

Summary Table:

| Key Factor | Impact on Required Tonnage |

|---|---|

| Part Projected Area | Larger area = Higher tonnage needed |

| Material Viscosity | Thicker materials (e.g., PC) = Higher tonnage |

| Part Complexity | Deep ribs/thin walls = Higher tonnage |

Need precise tonnage calculation for your injection molding project? KINTEK specializes in providing the right lab equipment and consumables for your R&D and production needs. Our experts can help you select the ideal machine size to ensure part quality, maximize efficiency, and control costs. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Small Injection Molding Machine for Lab Use

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Double Plate Heating Press Mold for Lab

- Powerful Plastic Crusher Machine

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

People Also Ask

- What can you make with an injection moulding machine? Mass-Produce High-Quality Plastic Parts Efficiently

- What is the manufacturing process of rubber molding? Injection, Compression, or Transfer Molding?

- What is the injection molding process? A Guide to High-Volume Part Production

- What is a positive of injection moulding? Achieve High-Volume Production with Unmatched Efficiency

- What is the application of injection moulding machine? Powering Mass Production for Complex Parts