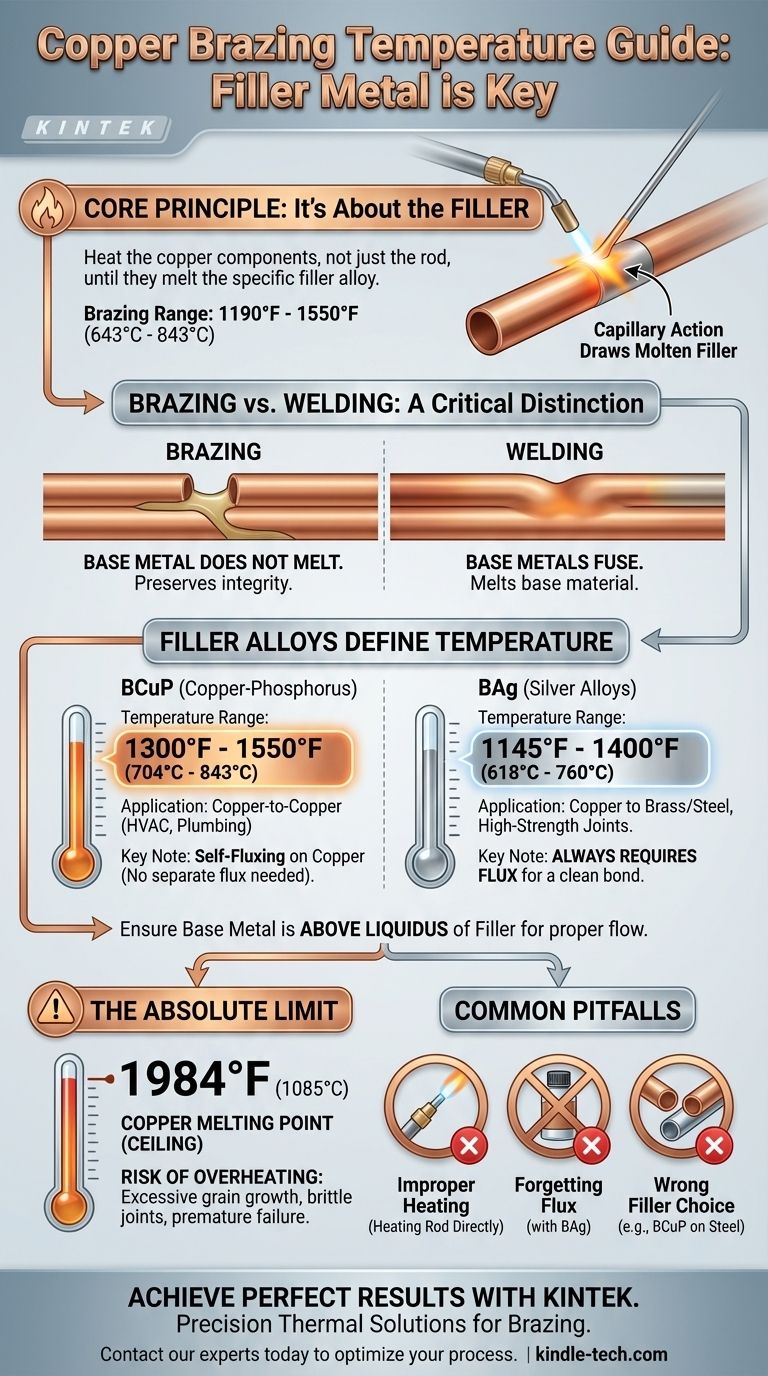

In short, copper brazing occurs at temperatures ranging from 1190°F to 1550°F (643°C to 843°C). This temperature is not a single value for copper itself, but is dictated entirely by the specific filler metal alloy being used to join the pieces. The goal is to melt the filler metal so it flows into the joint without melting the copper base metal.

The core principle of copper brazing is not about heating the copper to a specific temperature. It's about heating the copper components evenly until they are hot enough to melt a specific filler alloy, which then bonds them together.

Brazing vs. Welding: A Critical Distinction

To understand the temperature requirements, you must first understand the process. Brazing is fundamentally different from welding.

The Base Metal Does Not Melt

In brazing, only the filler metal melts. The copper parts being joined are heated, but they always remain solid.

This is a key advantage, as it preserves the original integrity and properties of the copper far better than welding, which melts and fuses the base metals.

The Filler Metal Creates the Bond

The bond is formed when the molten filler metal is drawn between the two closely-fitted copper surfaces via capillary action.

As the assembly cools, the filler solidifies, creating a strong, permanent metallurgical bond between the parts.

How Filler Alloys Define Brazing Temperature

The "brazing temperature" is the temperature to which you must heat the copper parts so they can melt the filler rod upon contact. This temperature is always higher than the melting point of the filler alloy.

Copper-Phosphorus (BCuP) Alloys

These are the most common alloys for joining copper to copper, particularly in HVAC and plumbing. Their key advantage is that they are self-fluxing on copper, meaning you don't need to add a separate chemical flux to clean the joint.

BCuP alloys typically have a brazing temperature range of 1300°F to 1550°F (704°C to 843°C).

Silver (BAg) Alloys

Often called "silver solders" (a misnomer, as they are true brazing alloys), these are used for higher-strength joints or for joining copper to other metals like brass or steel.

They have a lower working temperature, typically in the range of 1145°F to 1400°F (618°C to 760°C). Unlike BCuP alloys, silver alloys always require a separate flux to ensure a clean, strong bond.

Understanding 'Liquidus' and 'Solidus'

Every brazing alloy has a solidus temperature (where it starts to melt) and a liquidus temperature (where it is fully liquid). For proper brazing, the base metal must be heated to a temperature above the liquidus of the filler alloy to ensure it flows quickly and completely into the joint.

The Absolute Limit: Copper's Melting Point

It is physically impossible to braze copper at a temperature that is too high. You must stay safely below the melting point of the copper itself to avoid damaging or destroying your workpiece.

The Temperature Ceiling

The melting point of pure copper is 1984°F (1085°C). Your brazing temperature must always be significantly lower than this.

The Risk of Overheating

Even if you don't fully melt the copper, overheating can cause excessive grain growth in the metal's structure. This can make the copper brittle and weaken the area around the joint, leading to premature failure under stress or vibration.

Common Pitfalls to Avoid

Achieving the right temperature is a matter of technique and material selection. Missteps can lead to weak or failed joints.

Pitfall: Improper Heating

The most common mistake is heating the brazing rod directly with the torch instead of heating the copper parts. The heat of the base metal should melt the filler. This ensures the copper is hot enough for capillary action to work properly.

Pitfall: Forgetting Flux

When using a silver (BAg) alloy, or when joining copper to another metal, forgetting to apply flux is a critical error. The flux cleans the surfaces and protects them from oxidation during heating, allowing the filler metal to bond correctly.

Pitfall: Choosing the Wrong Filler

Using a self-fluxing BCuP alloy on a steel component will not work. The phosphorus that makes it self-fluxing on copper creates a brittle compound with iron (steel), resulting in a failed joint. You must match the filler to the base metals.

Making the Right Choice for Your Goal

Select your target temperature based on the filler alloy that best suits your project's materials and strength requirements.

- If your primary focus is standard copper-to-copper HVAC or plumbing: Use a BCuP alloy and heat the copper until it has a dull cherry-red glow, corresponding to a temperature of 1300°F - 1550°F (704°C - 843°C).

- If your primary focus is joining copper to brass or steel: Use a silver-based (BAg) alloy with the appropriate flux, targeting a temperature range of 1145°F - 1400°F (618°C - 760°C).

- If your primary focus is minimizing heat input to a sensitive assembly: Choose a silver alloy with the lowest possible working temperature that still provides the necessary joint strength.

Successful brazing is achieved not by hitting a magic number, but by controlling heat to suit the specific filler metal you've chosen for the job.

Summary Table:

| Filler Alloy Type | Common Applications | Brazing Temperature Range | Key Notes |

|---|---|---|---|

| Copper-Phosphorus (BCuP) | Copper-to-Copper (HVAC, Plumbing) | 1300°F - 1550°F (704°C - 843°C) | Self-fluxing on copper |

| Silver (BAg) | Copper to Brass/Steel, High-Strength Joints | 1145°F - 1400°F (618°C - 760°C) | Requires separate flux |

Achieve perfect copper brazing results with the right equipment and expertise. KINTEK specializes in high-temperature lab furnaces and heating solutions for precise thermal processes like brazing. Whether you're in HVAC, metalworking, or R&D, our equipment ensures accurate temperature control for strong, reliable joints.

Let us help you optimize your brazing process — Contact our experts today to discuss your specific application needs!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the factors that affect the strength of a brazed joint? Master the 4 Keys to a Perfect Bond

- What is the importance of a temperature-controlled heating device? Master the Synthesis of 1,3,4-oxadiazole Derivatives

- What are the hazards of heat treatment process? Avoid Oxidation, Embrittlement, and Costly Defects

- What can you make with an injection moulding machine? Mass-Produce High-Quality Plastic Parts Efficiently

- Is pyrolysis oil the same as crude oil? No, and here’s why the difference matters.

- How does a mechanical stirring device contribute to the uniformity of doped oxide coatings? Boost PEO Catalyst Quality

- What thickness is magnetron sputtering for coating? Achieve Precise, Functional Thin Films

- What features does the alarm system in ULT freezers include? Protect Your Samples with Multi-Layer Safety