There is no single temperature for annealing steel. The correct temperature is a precise calculation based entirely on the steel's specific carbon content and the desired outcome, typically falling between 540°C and 900°C (1000°F to 1650°F). For a full anneal, the target is generally 30-50°C (50-90°F) above the steel's upper critical temperature (A3 or Acm).

The critical takeaway is that annealing temperature isn't a generic recipe; it's a targeted intervention to manipulate steel's internal crystal structure. To select the right temperature, you must first identify your steel's chemistry and then define the specific property—like maximum softness or stress relief—you need to achieve.

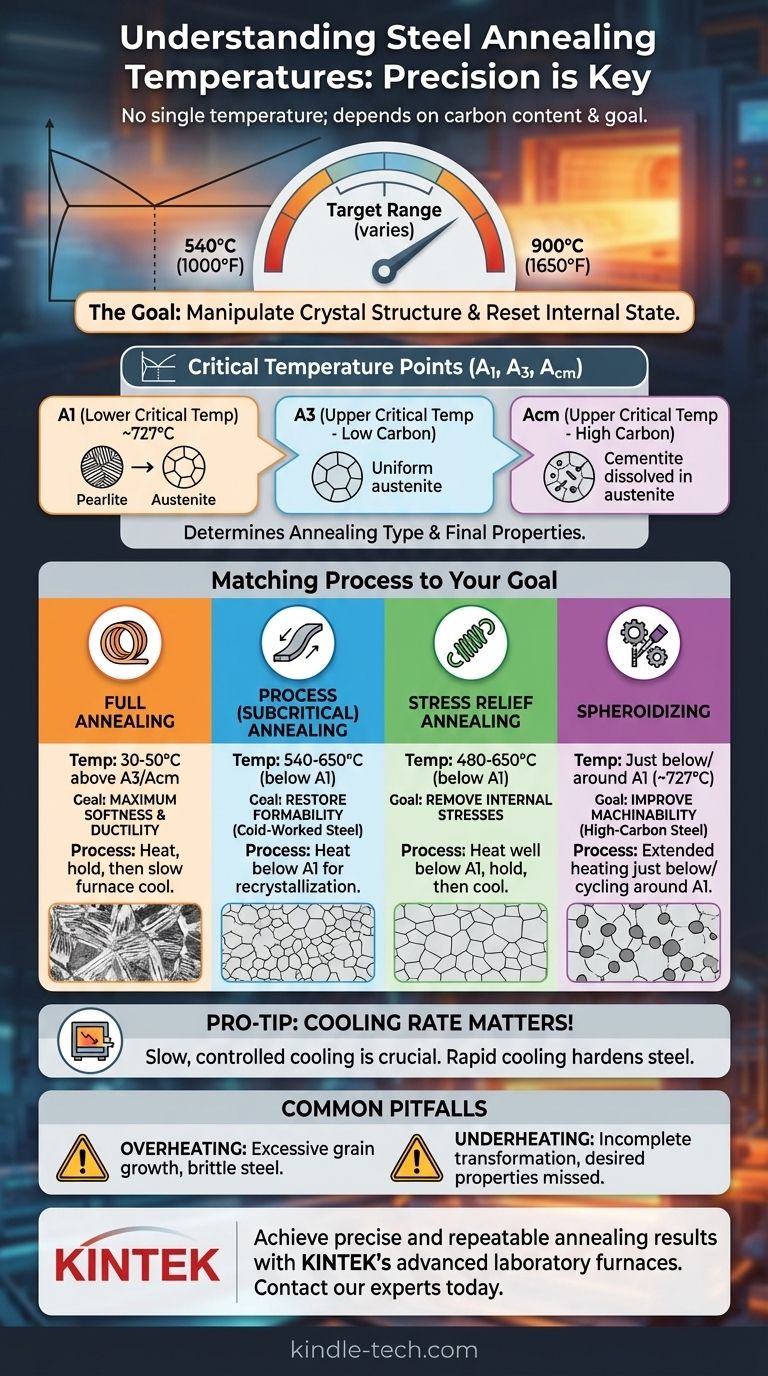

Why Temperature is the Critical Factor in Annealing

Annealing is fundamentally a process of heating and slow, controlled cooling designed to "reset" steel's internal structure. The goal is to make it softer, more ductile, and easier to machine or form. This transformation is governed by critical temperature points unique to each type of steel.

The Role of Critical Temperatures (A1, A3, Acm)

The behavior of steel during heat treatment is dictated by its phase diagram. The most important boundaries on this diagram are the critical temperatures.

- A1 (Lower Critical Temperature): Around 727°C (1340°F), this is the temperature where the pearlite structure begins to transform into austenite upon heating.

- A3 (Upper Critical Temperature): For steels with less than 0.77% carbon, this is the temperature at which the transformation to a uniform, single-phase austenite crystal structure is complete.

- Acm (Upper Critical Temperature): For steels with more than 0.77% carbon, this is the temperature at which all cementite has dissolved into the austenite.

Knowing whether your target temperature is above or below these points determines the type of annealing you are performing and the final properties of the material.

The Goal: A Controlled Microstructure

Heating the steel changes its crystal structure. A full anneal requires heating above the A3 or Acm to create a fully austenitic structure, which erases the effects of previous work hardening or improper heat treatment.

The subsequent slow cooling allows the crystals to reform in a highly ordered, stress-free way, typically resulting in a coarse pearlite structure. This new structure is what gives the steel its high ductility and low hardness.

Matching the Annealing Process to Your Goal

The term "annealing" can refer to several distinct processes, each with a different temperature range and purpose.

Full Annealing

This is the most common process, used to achieve the softest possible state. The steel is heated approximately 30-50°C (50-90°F) above its A3 or Acm temperature, held there long enough for the core to reach temperature, and then cooled extremely slowly, usually by leaving it in the insulated furnace to cool overnight.

Process (Subcritical) Annealing

This process is used on low-carbon steels that have been cold-worked. The temperature is kept below the A1 critical point, typically between 540-650°C (1000-1200°F). It doesn't change the phase but allows for recrystallization, which relieves internal stresses and restores ductility without affecting the overall hardness as much as a full anneal.

Stress Relief Annealing

When parts are heavily machined, welded, or cold-formed, they accumulate significant internal stress. A stress relief anneal heats the part to a temperature well below A1, usually around 480-650°C (900-1200°F), holds it, and then slowly cools it. This reduces stress without changing the material's core properties or microstructure.

Spheroidizing

Used primarily for high-carbon steels to improve machinability, this process involves heating to a temperature just below or cycling around the A1 line for an extended period. This encourages the hard cementite phase to form into small, round spheroids within the softer ferrite matrix, making the material much easier to cut.

Understanding the Trade-offs and Common Pitfalls

Selecting the right temperature is a balance. Deviating from the ideal parameters can have significant negative consequences.

The Danger of Overheating

Heating steel too far above its upper critical temperature (A3/Acm) can cause excessive grain growth. Large grains can make the steel brittle and weak, even after the annealing process is complete. This damage is often irreversible without significant re-working.

The Ineffectiveness of Underheating

For a full anneal, failing to reach the A3/Acm temperature means the steel's structure never fully transforms into austenite. The "reset" is incomplete, and you will not achieve the desired level of softness or ductility. The final material will be a mix of new and old structures.

Cooling Rate: The Other Half of the Equation

Temperature is only half the battle. The success of annealing is critically dependent on a slow, controlled cooling rate. Cooling too quickly, such as in open air, will not produce the soft, pearlitic structure of annealed steel. Instead, it can lead to the formation of harder structures like bainite or even martensite, effectively hardening the steel instead of softening it.

Choosing the Right Temperature for Your Steel

To apply this knowledge, you must first define your objective.

- If your primary focus is achieving maximum softness and ductility: You need a full anneal. Heat the steel 30-50°C (50-90°F) above its specific A3 or Acm line and cool it in the furnace.

- If your primary focus is restoring formability to a cold-worked, low-carbon steel: Use a process anneal. Heat the material to a temperature below the A1 line, typically 540-650°C (1000-1200°F).

- If your primary focus is improving the machinability of a high-carbon steel: Perform a spheroidizing anneal. Heat the steel to a temperature just below or around the A1 line (approx. 727°C / 1340°F) for an extended period.

- If your primary focus is simply removing internal stress from welding or machining: A stress relief anneal is sufficient. Heat the part well below the A1 line, typically between 480-650°C (900-1200°F).

Ultimately, mastering annealing requires treating temperature as a precise instrument to achieve a specific microstructural outcome.

Summary Table:

| Annealing Type | Temperature Range | Primary Goal |

|---|---|---|

| Full Anneal | 30-50°C above A3/Acm | Maximum softness & ductility |

| Process Anneal | 540-650°C (below A1) | Restore formability in cold-worked steel |

| Stress Relief | 480-650°C (below A1) | Remove internal stresses |

| Spheroidizing | Just below/around A1 (~727°C) | Improve machinability in high-carbon steel |

Achieve precise and repeatable annealing results with KINTEK's advanced laboratory furnaces.

Whether you're performing full annealing, stress relief, or spheroidizing, our equipment delivers the exact temperature control and uniform heating your steel requires. KINTEK specializes in lab equipment and consumables, serving the precise needs of metallurgical laboratories, research facilities, and manufacturing quality control.

Let us help you optimize your heat treatment process. Contact our experts today for a personalized solution!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan