In a professional laboratory setting, the appliance used is known as a laboratory oven. Unlike a conventional kitchen oven, this is a piece of precision equipment designed for scientific and industrial applications like drying glassware, curing materials, or performing complex thermal tests. Its purpose is not to cook, but to provide highly uniform and precisely controlled heat.

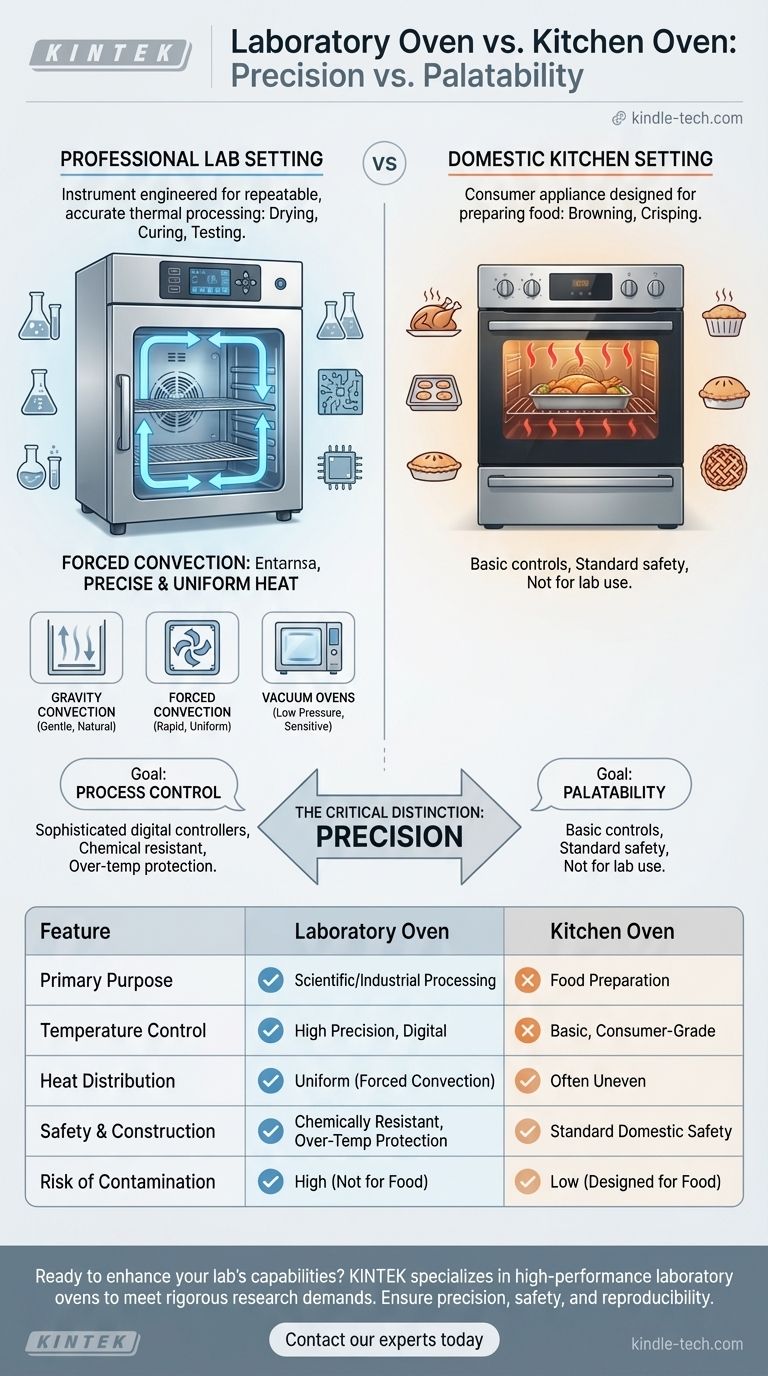

The critical distinction is that a laboratory oven is an instrument engineered for repeatable, accurate thermal processing, whereas a kitchen oven is a consumer appliance designed for preparing food.

What Defines a Laboratory Oven?

A laboratory oven is fundamentally different from a kitchen appliance. Its design choices are driven by the need for accuracy, consistency, and safety in a scientific or manufacturing environment.

Precision Temperature Control

Laboratory ovens use sophisticated digital controllers to maintain a set temperature with very little deviation. This precision is essential for experiments and processes where even a slight temperature change could ruin the result.

Uniform Heat Distribution

Achieving a consistent temperature throughout the entire chamber is paramount. Most lab ovens use forced convection (a fan) to circulate air, eliminating hot and cold spots that are common in standard ovens.

Specialized Applications

These ovens are multi-purpose tools. Their functions are essential for processes like drying substances, baking materials for specific tests, or curing polymers and epoxies in production procedures.

Robust Construction

They are typically built with chemically resistant materials like stainless steel to withstand harsh use. They also incorporate safety features like over-temperature protection to protect both the sample and the user.

Common Types of Laboratory Ovens

While "laboratory oven" is the general term, several specific types exist, each suited for different tasks based on how they circulate heat.

Gravity Convection Ovens

In these ovens, hot air naturally rises and circulates. This gentle airflow is ideal for drying fine powders or materials that could be disturbed by a fan. However, they are slower to heat and less uniform than forced convection models.

Forced Convection Ovens

Also known as mechanical convection ovens, these use a fan to actively circulate hot air. This results in superior temperature uniformity and faster drying or heating times, making them the standard for most general-purpose lab work.

Vacuum Ovens

This is a specialized oven that allows for drying materials in a low-pressure environment. This is critical for removing moisture from sensitive compounds at temperatures low enough to prevent them from degrading or reacting.

Understanding the Trade-offs: Lab Oven vs. Kitchen Oven

Using the wrong type of oven is not just inefficient; it can be dangerous and will produce invalid results.

The Goal: Precision vs. Palatability

A lab oven's goal is process control. It creates a stable, uniform thermal environment. A kitchen oven's goal is palatability, often relying on uneven heating (like a hot element at the top) to achieve browning and crisping.

The Risk of Contamination

Never use a kitchen oven for lab work or a lab oven for food. Lab ovens can be contaminated with hazardous chemicals, and using one for food poses a serious health risk. Conversely, food particles in a lab oven can contaminate sensitive experiments.

The Cost and Complexity

The precision components, durable construction, and safety certifications make laboratory ovens significantly more expensive and complex than consumer-grade kitchen appliances.

Making the Right Choice for Your Goal

Selecting the correct heating appliance is fundamental to achieving a safe and successful outcome, whether in a lab or a kitchen.

- If your primary focus is scientific research or industrial processing: You require a laboratory oven for its temperature precision, uniformity, and safety.

- If your primary focus is preparing food: A standard kitchen oven is the appropriate and safe tool designed specifically for cooking.

Ultimately, using the right instrument for the job is the first step toward reliable and meaningful results.

Summary Table:

| Feature | Laboratory Oven | Kitchen Oven |

|---|---|---|

| Primary Purpose | Scientific/Industrial Processing | Food Preparation |

| Temperature Control | High Precision, Digital | Basic, Consumer-Grade |

| Heat Distribution | Uniform (Forced Convection) | Often Uneven |

| Safety & Construction | Chemically Resistant, Over-Temp Protection | Standard Domestic Safety |

| Risk of Contamination | High (Not for Food) | Low (Designed for Food) |

Ready to enhance your lab's capabilities with the right equipment? KINTEK specializes in high-performance laboratory ovens, including gravity convection, forced convection, and vacuum models, designed to meet the rigorous demands of scientific research and industrial processing. Ensure precision, safety, and reproducibility in your work. Contact our experts today to find the perfect oven for your specific application!

Visual Guide

Related Products

- Laboratory Scientific Electric Heating Blast Drying Oven

- 1200℃ Muffle Furnace Oven for Laboratory

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

- Lab Internal Rubber Mixer Rubber Kneader Machine for Mixing and Kneading

People Also Ask

- What are the furnace used in metals? A Guide to Melting, Alloying, and Heat Treatment

- Why is it necessary to use a mechanical stirrer or shaker during azo dye degradation experiments? Optimize Your Results

- What is the difference between batch furnace and continuous furnace? Choose the Right System for Your Production Volume

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- Is pyrolysis of plastic harmful? The Truth About Toxic Byproducts and Environmental Risks

- What is a fused sample? Achieve Unmatched Accuracy in Elemental Analysis

- How do ultrasonic homogenizers or cell disruptors enhance the digestion efficiency of substrates in dark fermentation? Boost Bio-Availability

- What industries use heat treatment? A Guide to Enhancing Material Performance Across Sectors