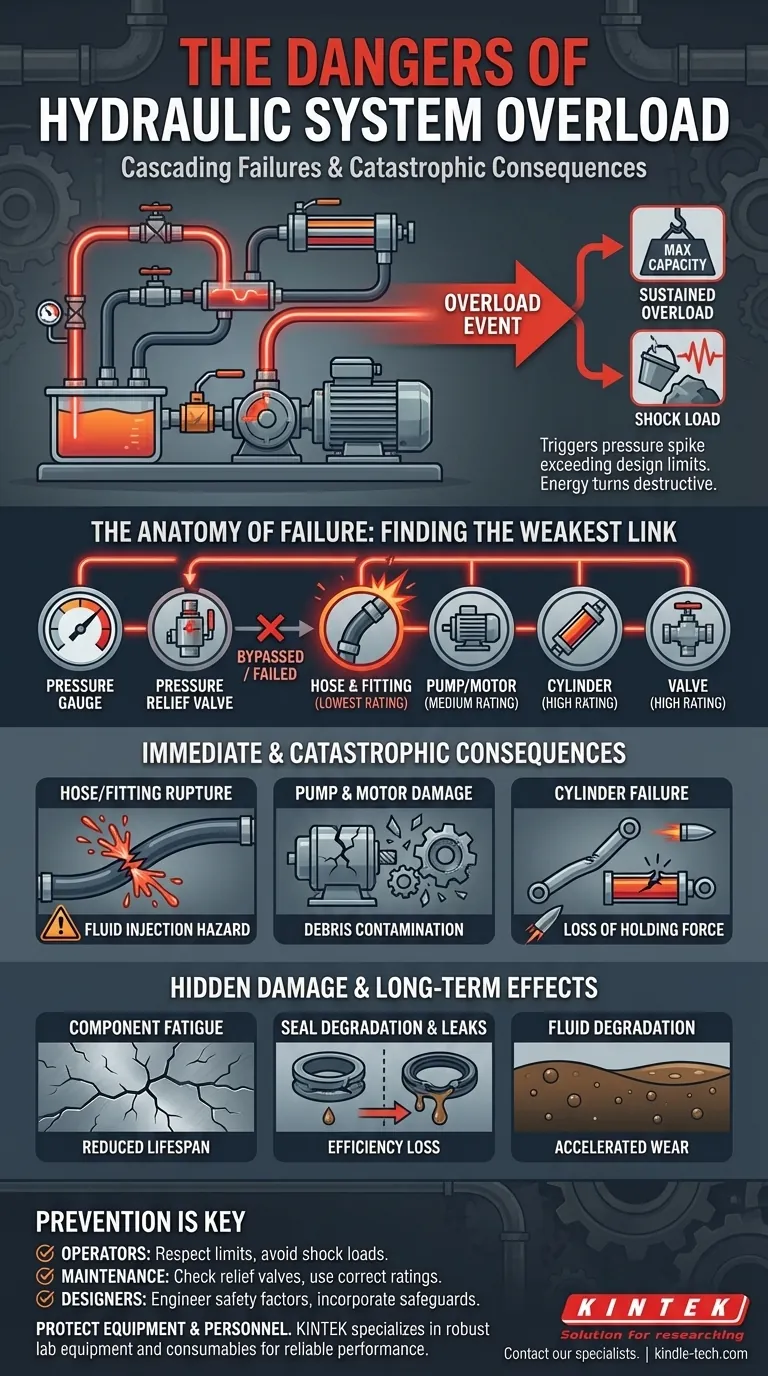

Overloading a hydraulic system triggers a cascade of failures, starting with the weakest component. An overload event, whether from a sudden shock or a sustained high load, causes a rapid pressure spike that exceeds the system's design limits. This can instantaneously burst hoses, shatter fittings, damage pumps and motors, or cause catastrophic failure of cylinders, releasing high-pressure fluid and creating an immediate and severe safety hazard.

The core issue is not simply that one part breaks, but that an overload turns the immense stored energy of the hydraulic system into a destructive force. The pressure will find the path of least resistance, guaranteeing that the component with the lowest pressure rating fails first, often with explosive force that can lead to a chain reaction of damage.

The Anatomy of a Hydraulic Overload

To understand the consequences, you must first understand what happens inside the system when it's pushed beyond its limits. It's a contest between rising pressure and the mechanical strength of the components.

What Defines an "Overload"?

An overload isn't just about lifting too much weight. It can manifest in two primary ways:

- Sustained Overload: This occurs when the system is commanded to do work beyond its rated capacity, such as trying to lift a load that is too heavy. The pressure steadily builds as the pump tries to move the actuator.

- Shock Load: This is a sudden, high-energy pressure spike. It often happens when an actuator moving at high speed is stopped abruptly, like an excavator bucket hitting solid rock. The momentum of the moving fluid and components creates a powerful pressure wave, much like a water hammer effect.

The First Line of Defense: The Relief Valve

Nearly every hydraulic system has a pressure relief valve. Its sole job is to act as a safety bypass. When pressure hits a preset limit, the valve opens, diverting excess fluid flow back to the reservoir.

However, this protection can fail. If the relief valve is improperly set, has malfunctioned, or simply cannot react fast enough to an extreme shock load, the pressure continues to build, and the system is left unprotected.

The Chain of Failure: Finding the Weakest Link

Once the relief valve is bypassed or overwhelmed, the immense pressure searches for the next weakest point. Every component in the system—hoses, fittings, pumps, cylinders, valves—has a specific pressure rating. The first one to fail is the one with the lowest rating.

Immediate and Catastrophic Consequences

When a component fails under extreme pressure, the results are immediate, violent, and dangerous.

Hose and Fitting Ruptures

This is the most common failure point. A hydraulic hose will burst with an explosive bang, releasing a spray or jet of hot, high-pressure fluid. This presents a severe fluid injection hazard, where hydraulic oil can penetrate the skin and cause grievous injury that requires immediate surgical intervention.

Pump and Motor Damage

Excessive pressure can destroy the tight internal tolerances of a pump or motor. It can crack the housing, shear the drive shaft, or shatter internal components like gears, vanes, or pistons. This results in a total loss of function and sends metal debris throughout the entire hydraulic system, causing widespread secondary damage.

Cylinder and Actuator Failure

Cylinders are also highly vulnerable. The pressure can blow out the piston seals, causing a total loss of holding force. In more extreme cases, the cylinder rod can bend or buckle, or the cylinder barrel itself can rupture, turning it into a projectile.

Hidden Damage and Long-Term Effects

Not every overload event results in a spectacular failure. Sometimes, the damage is more subtle, leading to reduced performance and a drastically shortened equipment lifespan.

Component Fatigue

Pressure spikes that don't cause immediate failure still place immense stress on all metal components. This repeated stress leads to metal fatigue and the formation of micro-fractures, which will eventually grow into a full-blown failure under normal operating conditions.

Seal Degradation and Leaks

High-pressure events can deform or extrude the soft seals used throughout the system. This damage leads to persistent internal or external leaks, which reduce system efficiency, waste energy, and can lead to eventual component failure due to fluid starvation.

Fluid Degradation

Extreme pressure generates significant heat. This heat can break down the hydraulic fluid, destroying its lubricating properties and additives. Degraded fluid accelerates wear on every component in the system.

Making the Right Choice for Your Goal

Understanding these risks is the first step toward preventing them. Your approach depends on your role.

- If your primary focus is operating machinery: Respect the equipment's rated limits, avoid sudden and jerky movements that cause shock loads, and immediately stop work if you hear unusual noises or see leaks.

- If your primary focus is maintenance: Always ensure pressure relief valves are set correctly and are functioning, and never replace a component (like a hose) with one that has a lower pressure rating than the original.

- If your primary focus is system design: Always engineer the system with a sufficient safety factor, properly sizing all components and incorporating safeguards like relief valves and accumulators to absorb pressure spikes.

Ultimately, preventing hydraulic overload is about respecting the controlled, high-density power that makes these systems so effective.

Summary Table:

| Consequence | Primary Cause | Key Impact |

|---|---|---|

| Hose/Fitting Rupture | Pressure exceeds component rating | Fluid injection hazard, immediate system failure |

| Pump/Motor Damage | Excessive pressure destroys internal tolerances | Total loss of function, metal debris contamination |

| Cylinder Failure | Pressure blows seals or ruptures barrel | Loss of holding force, potential projectile hazard |

| Component Fatigue | Repeated stress from pressure spikes | Shortened lifespan, micro-fractures leading to future failure |

| Seal Degradation & Leaks | High-pressure deforms or extrudes seals | Reduced efficiency, fluid starvation, energy waste |

Protect your equipment and personnel from the dangers of hydraulic overload. KINTEK specializes in providing robust lab equipment and consumables designed for reliable performance under demanding conditions. Our expertise ensures your systems operate safely and efficiently, minimizing downtime and maximizing productivity. Contact our hydraulic specialists today to discuss your specific laboratory needs and discover how we can help you maintain a safe and reliable operation.

Visual Guide

Related Products

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- What role does a laboratory hydraulic press play in ceramic membrane preparation? Master Your Material's Microstructure

- What machine is used to make pellets? The Complete Guide to Pellet Mills & Production Systems

- Why is a pre-pressing step using a laboratory hydraulic press necessary? Key to Stable Particleboard Mats

- What is the Bernoulli's principle of hydraulic press? It's Actually Pascal's Law That Powers It

- What are the preventive maintenance of hydraulic press machine? Maximize Uptime and Prevent Costly Failures

- What does the efficiency of the hydraulic system depend on? Minimize Volumetric & Mechanical Losses

- What is the role of a laboratory hydraulic press in Rare Earth Element (REE) analysis? Unlock High-Precision XRF & LIBS

- How much force can a hydraulic press produce? From 1 to 100,000+ Tons of Power