At first glance, a heat press and a household iron appear to do the same thing: get hot and press onto fabric. The fundamental difference, however, lies in three critical areas: the consistency of heat, the uniformity of pressure, and the size of the application surface. An iron is designed to glide over fabric to remove wrinkles, while a heat press is engineered to deliver precise, even heat and pressure to a fixed area, permanently bonding a design to a substrate.

The core distinction is one of purpose and precision. A household iron is a tool for finishing clothes, offering inconsistent heat and manual pressure. A heat press is a specialized machine for manufacturing, providing the controlled and repeatable environment required for professional, durable heat transfers.

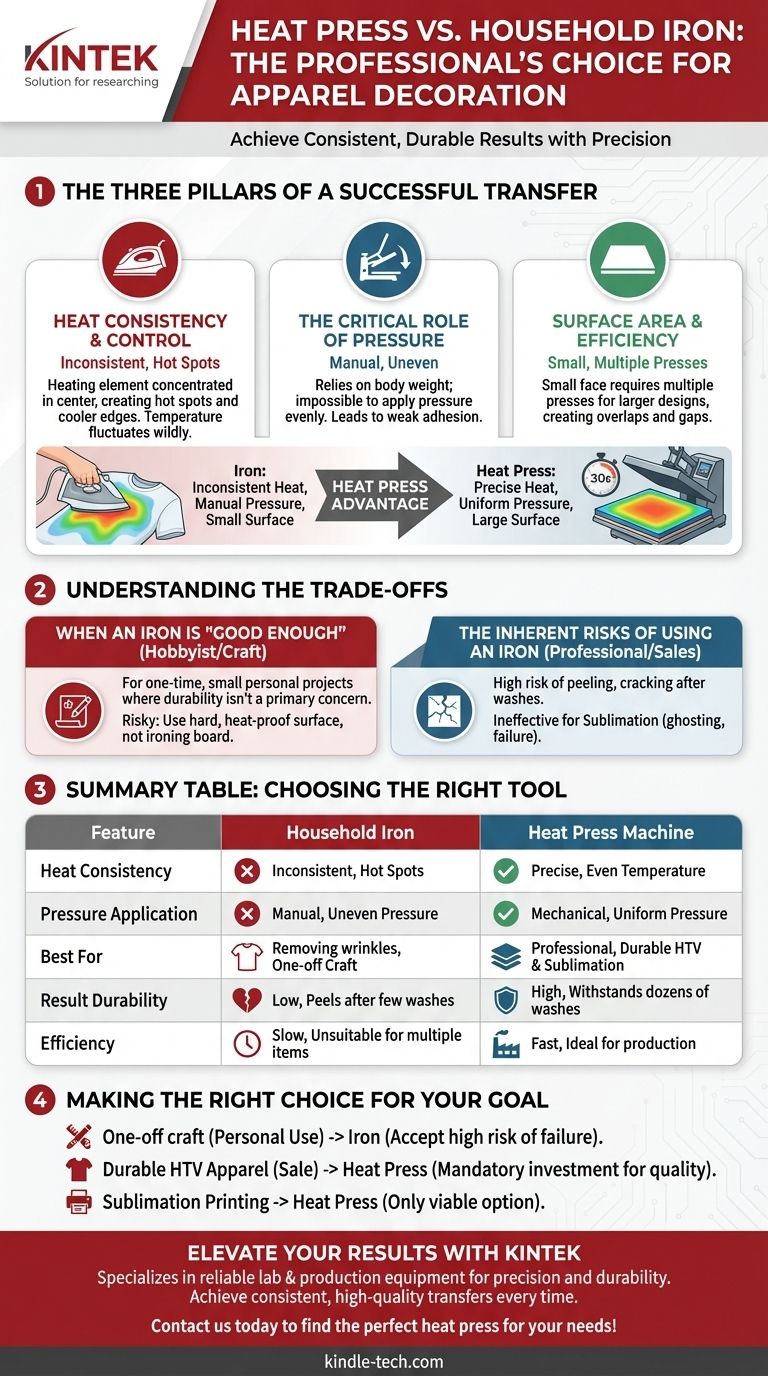

The Three Pillars of a Successful Transfer

To understand why a heat press is superior for apparel decoration, you must first understand the three variables that determine the success and durability of any heat-applied graphic: temperature, pressure, and time.

Heat Consistency and Control

A household iron's heating element is concentrated in the center, creating significant "hot spots" and cooler edges. The temperature you select on the dial is an approximation at best and fluctuates wildly as the iron is used.

This inconsistency is a major problem for heat transfer materials, which have specific temperature windows for proper adhesion. Too cold, and the adhesive won't activate. Too hot, and you can scorch the fabric or ruin the transfer.

A heat press, by contrast, uses a grid of heating elements embedded within a thick metal platen. This design, combined with a digital thermostat, ensures the entire surface maintains a precise and consistent temperature with minimal fluctuation.

The Critical Role of Pressure

An iron relies entirely on your body weight and strength to apply pressure. It is impossible to apply pressure evenly across the entire design, especially with one hand. This results in some parts of the design adhering strongly while others barely stick.

A heat press uses a mechanical clamping system (either a clamshell or swing-away design) to deliver uniform, measurable pressure across the entire platen. This consistent pressure is non-negotiable for forcing the adhesive into the fibers of the garment, creating a bond that can withstand dozens of washes.

Surface Area and Efficiency

The face of an iron is small and shaped for navigating collars and seams. Applying a design larger than the iron itself requires you to press multiple times, creating overlaps and gaps that lead to an unprofessional finish.

A heat press has a large, flat surface (commonly 15"x15" or larger) that can accommodate most standard-sized designs in a single press. This is not only crucial for quality but also for efficiency if you are producing more than one item.

Understanding the Trade-offs

While a heat press is professionally superior, it's important to acknowledge the context where an iron might be considered. The choice is a direct trade-off between cost and quality.

When an Iron Is "Good Enough"

For a one-time, small, personal project where durability is not the primary concern, an iron can work. If you are just experimenting with a small piece of Heat Transfer Vinyl (HTV) for a craft, you may achieve a temporary result.

If you must use an iron, never use an ironing board. Its padded, mesh surface absorbs heat and prevents even pressure. Always work on a hard, heat-proof, flat surface like a wooden block or countertop protected by a Teflon sheet.

The Inherent Risks of Using an Iron

Using an iron for anything beyond a simple hobbyist test invites failure. HTV applied with an iron is significantly more likely to peel, crack, or lift after just one or two washes.

For processes like sublimation, which requires precise, high heat to turn ink into a gas, an iron is completely ineffective. The uneven heating will result in "ghosting," blotchy colors, and a failed transfer every time.

Cost vs. Investment

The most obvious advantage of an iron is its low cost and accessibility. However, if your goal is to create sellable products, viewing the cost of a heat press as an expense is a mistake. It is a one-time investment in quality control, efficiency, and professional reputation.

Making the Right Choice for Your Goal

Your choice of tool should be determined by the intended outcome of your project.

- If your primary focus is a one-off craft for personal use: An iron can be a starting point, but you must accept the high risk of a low-quality, non-durable result.

- If your primary focus is creating durable HTV apparel for yourself or for sale: A heat press is a mandatory investment for consistent, professional-quality products that will last.

- If your primary focus is sublimation printing: A heat press is the only viable option, as the process is impossible to execute correctly with an iron.

Ultimately, choosing the right tool is the first step in ensuring your creative vision becomes a durable, professional reality.

Summary Table:

| Feature | Household Iron | Heat Press Machine |

|---|---|---|

| Heat Consistency | Inconsistent, with hot spots | Precise, even temperature across entire platen |

| Pressure Application | Manual, uneven pressure | Mechanical, uniform and measurable pressure |

| Best For | Removing wrinkles, one-off craft tests | Professional, durable HTV and sublimation transfers |

| Result Durability | Low, may peel after few washes | High, withstands dozens of washes |

| Efficiency | Slow, unsuitable for multiple items | Fast, ideal for production and sales |

Ready to elevate your apparel decoration with professional-grade results?

KINTEK specializes in reliable lab and production equipment, including heat press machines designed for precision and durability. Whether you're starting a small business or scaling production, our heat presses ensure consistent, high-quality transfers every time.

Contact us today to find the perfect heat press for your needs and achieve lasting, professional results!

Visual Guide

Related Products

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Heat Press Machine

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What role does a pressure curing device play in metal-resin bonding? Ensure Flawless Specimen Integrity

- What is a thermistor on a heat press? The Key to Consistent, Professional Transfers

- What temperature should a hot plate be? Achieve Safe and Precise Heating for Your Lab

- How does the use of a laboratory hot press influence TlBr crystal quality? Master High-Density Semiconductor Production

- Why must electric heating elements be wrapped around the pellet forming die? Boost Oat Straw Pellet Quality

- What is a 3D sublimation heat press? Unlock Full-Wrap Printing on Curved Objects

- What role does a hot press play in treating the CAL-GPE interface? Optimize Performance for Flexible Lithium Batteries

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production