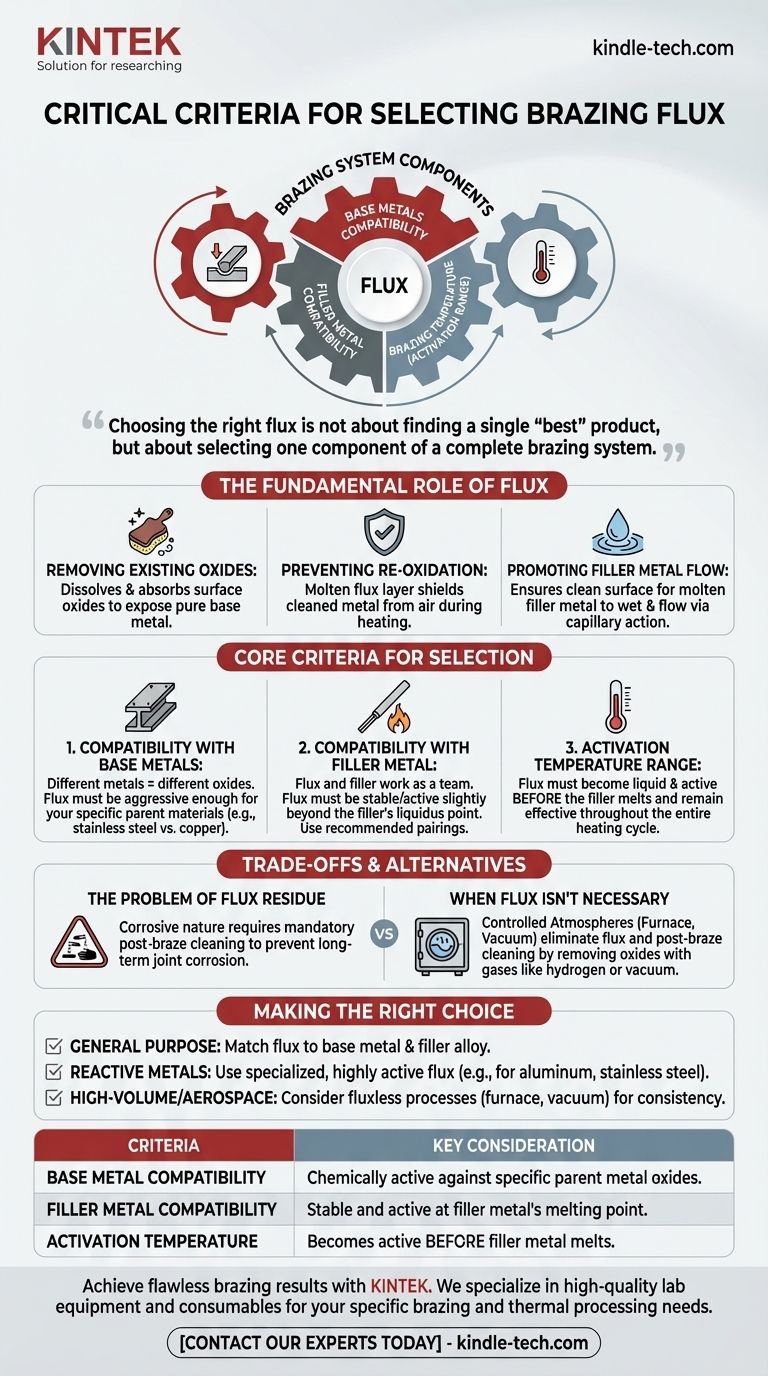

In selecting a brazing flux, the critical criteria are its compatibility with your base metals, your filler metal alloy, and the required brazing temperature. The flux must be chemically active enough to clean the specific metals you are joining and must function correctly within the heat range where your filler metal becomes liquid and flows.

Choosing the right flux is not about finding a single "best" product, but about selecting one component of a complete brazing system. The flux's primary job is to ensure a chemically clean surface at the precise temperature your filler metal needs to create a strong, permanent bond.

The Fundamental Role of Flux in Brazing

To select a flux, you must first understand its purpose. Flux is an aggressive chemical agent that performs several critical functions during the heating process to enable a successful braze joint.

Removing Existing Oxides

All metals, even if they appear clean, have a layer of metal oxide on their surface. Flux contains chemicals that dissolve and absorb these oxides, exposing the pure base metal underneath.

Preventing Re-Oxidation

As you heat the parts, the rate of oxidation increases dramatically. A layer of molten flux shields the cleaned base metal from the surrounding air, preventing new, stubborn oxides from forming at brazing temperature.

Promoting Filler Metal Flow

By creating a perfectly clean and shielded surface, flux allows the molten filler metal to "wet" the base metals. This wetting action is what allows capillary action to draw the filler metal deep into the joint for maximum strength.

Core Criteria for Flux Selection

With a clear understanding of its role, you can now evaluate a flux based on three primary technical criteria.

Compatibility with Base Metals

Different metals produce different types of oxides. A flux designed for copper and brass will not be aggressive enough to remove the tough, chromium-oxide layer on stainless steel. You must choose a flux specifically formulated to be active against the oxides of your parent materials.

Compatibility with Filler Metal

Flux and filler metals are designed to work as a team. The flux must remain stable and active up to, and slightly beyond, the liquidus (flow point) of your specific brazing alloy. For this reason, manufacturers often recommend or sell specific flux-and-alloy pairings.

Activation Temperature Range

Every flux has an active temperature range. It must become liquid and begin cleaning the metal before the filler alloy melts. It must also remain effective throughout the entire heating cycle without breaking down or becoming exhausted too early.

Understanding the Trade-offs and Alternatives

While essential for many applications, chemical flux is not a universal solution. Understanding its limitations is key to making an expert decision.

The Problem of Flux Residue

The chemicals that make flux effective are, by their nature, corrosive. After brazing, any remaining flux residue can absorb moisture from the air and actively corrode the finished joint and base metals over time. Post-braze cleaning is not optional; it is a required process step.

When Flux Isn't Necessary: Controlled Atmospheres

In many high-volume or high-purity applications, flux is eliminated entirely. Processes like furnace brazing or vacuum brazing replace chemical flux with a carefully controlled atmosphere.

Gases like hydrogen, or the absence of atmosphere in a vacuum, perform the same function as flux: they remove and prevent oxides from forming. This eliminates the need for post-braze cleaning, resulting in cleaner joints and often a more streamlined production process.

Making the Right Choice for Your Application

Use your specific goal to guide your final selection.

- If your primary focus is general-purpose torch brazing: Choose a flux that is explicitly matched by the manufacturer to both your base metal (e.g., steel, copper) and the specific filler alloy you are using.

- If your primary focus is joining reactive metals like aluminum or stainless steel: You must use a specialized, highly active flux designed for those specific metals, as standard fluxes will fail.

- If your primary focus is high-volume production or aerospace-grade quality: Investigate fluxless processes like furnace or vacuum brazing to improve consistency and eliminate the cost and risk of post-braze cleaning.

By treating flux as a critical component of the entire brazing system, you ensure strong, reliable, and durable joints for your application.

Summary Table:

| Criteria | Key Consideration |

|---|---|

| Base Metal Compatibility | Flux must be chemically active against the specific oxides of the parent metals (e.g., stainless steel requires a stronger flux than copper). |

| Filler Metal Compatibility | Flux must remain stable and active at the filler metal's melting point; use manufacturer-recommended pairings. |

| Activation Temperature | Flux must become active before the filler metal melts and remain effective throughout the heating cycle. |

Achieve flawless brazing results with the right equipment and consumables.

Selecting the correct flux is just one part of a successful brazing operation. KINTEK specializes in providing high-quality lab equipment and consumables tailored to your specific brazing and thermal processing needs. Whether you are working on R&D, quality control, or production, our expertise ensures you have the right tools for strong, reliable joints.

Let us help you optimize your process. Contact our experts today to discuss your application requirements!

Visual Guide

Related Products

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Warm Isostatic Press for Solid State Battery Research

- No Demolding Lab Infrared Press Mold for Laboratory Applications

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- What are the advantages of a colloidal mill? Achieve Superior Emulsification and High-Throughput Processing

- Why are stirring or homogenizing devices essential in phase inversion? Achieve Perfect Photocatalytic Membrane Dispersion

- What is the function of high-shear dispersion equipment in corona-resistant nanocomposites? Elevate Your Insulation

- What functions do laboratory centrifuges and high-shear homogenizers perform? Optimize Your Nano-Modified Composites

- What are the advantages of using a high-shear homogenizer for BED/GMA coatings? Achieve Superior Nano-Dispersion