In short, the sintering process is used to manufacture solid objects from powders, with its most common applications found in powder metallurgy (for metals), ceramics manufacturing (from pottery to advanced components), and even for certain plastics and biomaterials. It is a thermal treatment for compacting and forming a solid mass of material by heat and pressure without melting it to the point of liquefaction.

The core value of sintering is its ability to create dense, strong parts from powders at temperatures below their melting point. This makes it the essential process for working with extremely high-melting-point materials or for creating unique composite materials that cannot be made through traditional melting and casting.

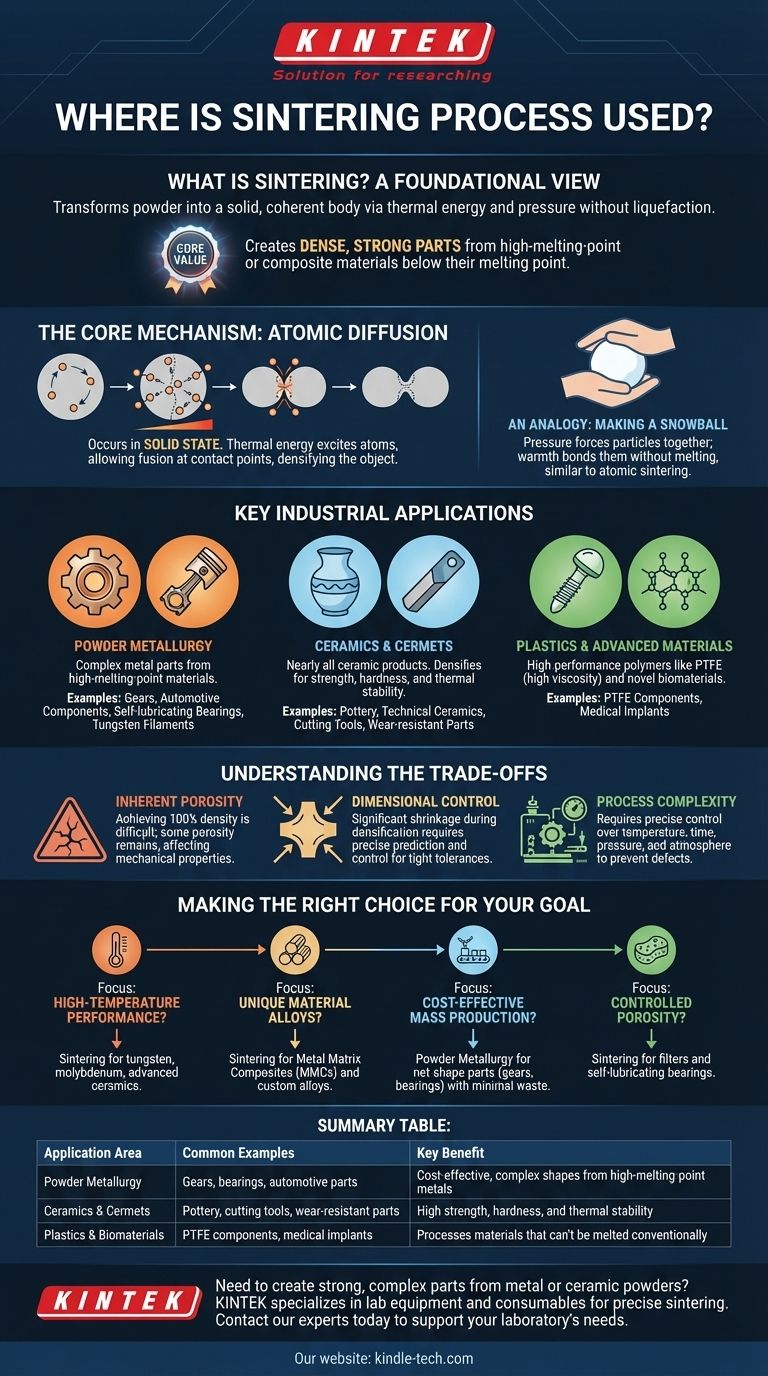

What is Sintering? A Foundational View

Sintering is a manufacturing process that transforms a powder into a solid, coherent body. This is achieved by applying thermal energy, and often pressure, to a pre-shaped component made from the powder.

The Core Mechanism: Atomic Diffusion

The key to sintering is that it occurs entirely in the solid state. The temperature is raised high enough to excite the atoms and make them mobile, but below the material's melting point.

This atomic mobility allows particles to fuse together at their contact points. Over time, these connection points grow, pores between the particles shrink, and the entire object becomes denser and stronger.

An Analogy: Making a Snowball

Think of packing loose snow into a solid snowball. You apply pressure to force the snowflakes together. The warmth from your hands (a form of thermal energy) helps the ice crystals bond without melting the whole ball into water. Sintering operates on a similar principle at a microscopic, atomic level.

Key Industrial Applications

Sintering is not a niche process; it is a cornerstone of modern manufacturing for a wide range of materials.

Powder Metallurgy

This is one of the largest applications of sintering. It is used to create complex metal parts, especially from materials that are difficult to machine or have very high melting points.

Common examples include gears, automotive components, self-lubricating bearings (where porosity is intentionally retained to hold oil), and the tungsten filaments in incandescent light bulbs.

Ceramics and Cermets

Nearly all ceramic products, from household pottery and porcelain to advanced technical ceramics, are made using sintering. Fragile green bodies made of clay or other ceramic powders are fired in a kiln.

This process densifies the material, giving it the required strength, hardness, and thermal stability. This also applies to cermets—composites of ceramic and metal—used for cutting tools and wear-resistant parts.

Plastics and Advanced Materials

While less common, sintering is used for certain high-performance polymers like Polytetrafluoroethylene (PTFE). Because PTFE has an extremely high viscosity even when melted, it cannot be processed using conventional plastic molding techniques.

Sintering is also critical in advanced research, such as in the creation of novel biomaterials for medical implants, where precise control over the material's final structure is required.

Understanding the Trade-offs

While powerful, sintering is not a universal solution. It's important to understand its limitations to know when it is the right choice.

Inherent Porosity

Achieving 100% density is often difficult or prohibitively expensive. Most sintered parts retain a small amount of porosity, which can affect mechanical properties like tensile strength and fatigue resistance compared to a fully dense, wrought equivalent.

Dimensional Control

The material shrinks significantly as it densifies during sintering. Predicting and controlling this shrinkage to achieve tight final tolerances can be challenging and may require secondary finishing operations.

Process Complexity

Effective sintering requires precise control over temperature, time, pressure, and the furnace atmosphere to prevent oxidation or unwanted chemical reactions. This makes it a more complex and knowledge-intensive process than simple casting.

Making the Right Choice for Your Goal

Selecting sintering depends entirely on your material and performance requirements.

- If your primary focus is high-temperature performance: Sintering is the go-to method for creating components from materials with extremely high melting points, such as tungsten, molybdenum, and advanced ceramics.

- If your primary focus is creating unique material alloys: Sintering is ideal for producing metal matrix composites (MMCs) or custom alloys that are difficult or impossible to create through melting.

- If your primary focus is cost-effective mass production of small, complex parts: Powder metallurgy, which relies on sintering, is a leading technology for producing net-shape or near-net-shape parts like gears and bearings with minimal material waste.

- If your primary focus is controlled porosity: Sintering is the only practical way to manufacture components with a deliberately porous structure, such as filters or self-lubricating bearings.

By understanding its fundamental principles, you can leverage sintering to solve manufacturing challenges that other processes simply cannot address.

Summary Table:

| Application Area | Common Examples | Key Benefit |

|---|---|---|

| Powder Metallurgy | Gears, bearings, automotive parts | Cost-effective, complex shapes from high-melting-point metals |

| Ceramics & Cermets | Pottery, cutting tools, wear-resistant parts | High strength, hardness, and thermal stability |

| Plastics & Biomaterials | PTFE components, medical implants | Processes materials that can't be melted conventionally |

Need to create strong, complex parts from metal or ceramic powders? The sintering process is your solution. KINTEK specializes in the lab equipment and consumables needed for precise sintering, helping you achieve the density, strength, and material properties required for your application. Contact our experts today to discuss how we can support your laboratory's sintering and materials manufacturing needs.

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Is induction brazing better than furnace brazing? Choose the Right Brazing Method for Your Application

- What is the primary function of a high vacuum furnace in heat treating stainless steel? Precision Microstructural Control

- What is the primary function of a high-temperature furnace in thermal stability testing? Ensure Inhibitor Performance

- What are the advantages of vacuum sintering? Achieve Superior Purity, Strength, and Performance

- What critical conditions must a furnace provide for 1.25Cr-0.5Mo austenitization? Achieve Precise Thermal Control

- What is powder sintering? A Guide to Efficient High-Performance Part Manufacturing

- What role do high-temperature annealing furnaces and water quenching systems play in the post-processing of PM-HIP joints?

- In what industry is brazing mainly used? A Guide to High-Strength Joining in Aerospace, Automotive & More