The primary mechanism used in a modern press machine is a hydraulic system that operates based on Pascal's Law. This system uses an incompressible fluid, typically oil, to translate a small applied force into a much larger output force, enabling the machine to generate immense compressive power.

At its core, a hydraulic press functions by exploiting a fundamental principle of fluid dynamics: pressure applied to a confined liquid is distributed evenly. This allows a small input force on a small piston to be multiplied into a massive output force on a larger piston, creating the mechanical advantage needed for pressing operations.

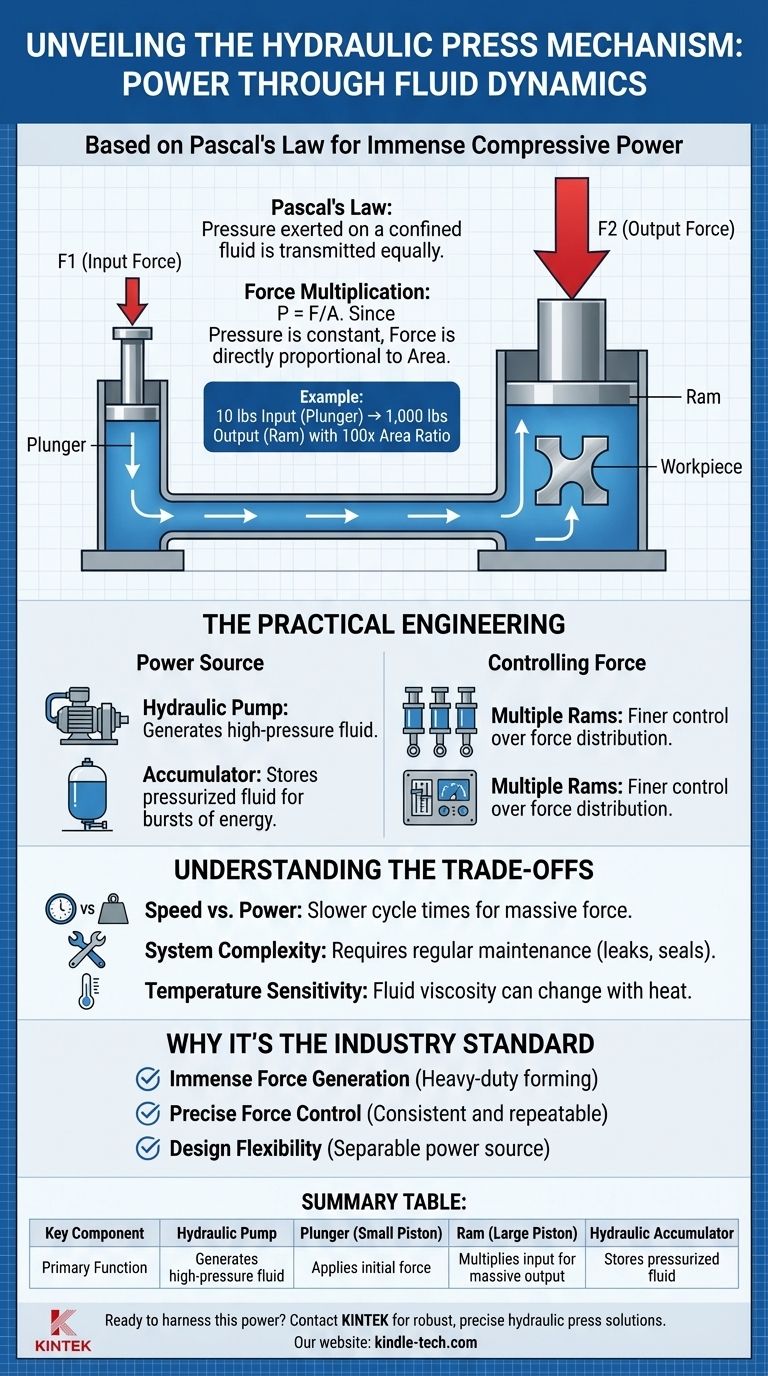

How a Hydraulic Press Achieves Force Multiplication

The genius of the hydraulic press lies in its elegant use of fluid properties to create power. The entire operation is governed by a simple, yet profound, physical law.

The Role of Pascal's Law

The foundational principle is Pascal's Law, which states that pressure exerted on a confined fluid is transmitted equally throughout that fluid.

Since pressure is defined as Force divided by Area (P = F/A), this principle has a powerful implication. If the pressure is constant throughout the system, the force exerted by the fluid is directly proportional to the area over which it acts.

The Core Components in Action

A basic hydraulic press consists of two main cylinders connected by a pipe, both filled with hydraulic fluid like oil.

A small-diameter piston, often called the plunger, receives a small initial force. This action pressurizes the fluid within the system.

This pressure then acts on a much larger-diameter piston, known as the ram. Because the ram has a significantly larger surface area, the same pressure results in a much greater output force, which is used to crush or press the object.

The Math Behind the Power

Imagine the ram has a surface area 100 times greater than the plunger.

According to Pascal's Law, a 10-pound force applied to the plunger will generate a powerful 1,000-pound force at the ram. This force multiplication is the central advantage of the hydraulic mechanism.

The Practical Engineering of a Hydraulic System

While the principle is simple, a real-world press machine includes several key components to make it a reliable and controllable industrial tool.

The Power Source: Pumps and Accumulators

To achieve the necessary pressure, a pump is used to supply high-pressure liquid to the system.

In many designs, a hydraulic accumulator is also used. This device stores the high-pressure fluid, acting like a rechargeable battery. It releases this stored energy in a powerful burst when the press requires maximum thrust.

Controlling the Force: Single vs. Multiple Rams

Instead of one massive ram, it is common for heavy-duty presses to use multiple smaller rams.

This approach provides finer control over the distribution of force across the workpiece, which is critical for precision tasks and managing the immense loads involved. The number of rams is selected based on the specific working load of the machine.

Understanding the Trade-offs

While incredibly powerful, the hydraulic mechanism is not without its operational considerations. Understanding these trade-offs is key to its effective application.

Speed vs. Power

Hydraulic systems are masters of force but are often slower than purely mechanical presses. The time it takes to move fluid and build pressure means the cycle time can be longer.

System Complexity and Maintenance

A hydraulic system relies on a network of pumps, hoses, cylinders, and seals. This introduces a need for regular maintenance to prevent and address fluid leaks, which can compromise the system's pressure and efficiency.

Temperature Sensitivity

The performance of the hydraulic fluid can be affected by temperature. As the oil heats up during operation, its viscosity can change, which may slightly alter the machine's performance characteristics.

Why This Mechanism is the Industry Standard

The choice of a hydraulic mechanism is a deliberate engineering decision driven by its unique advantages for high-force applications.

- If your primary focus is immense force generation: The hydraulic mechanism's ability to multiply force based on piston area makes it unparalleled for heavy-duty forming, forging, and crushing.

- If your primary focus is precise force control: Hydraulic systems allow for excellent and consistent control over the pressure applied, enabling highly precise and repeatable operations.

- If your primary focus is design flexibility: The use of fluids and hoses allows the power source (the pump) to be located away from the press itself, offering significant flexibility in machine design and factory layout.

Understanding this core principle of fluid mechanics is the key to appreciating the power and versatility of the modern press machine.

Summary Table:

| Key Component | Primary Function |

|---|---|

| Hydraulic Pump | Generates high-pressure fluid to power the system |

| Plunger (Small Piston) | Applies initial force to pressurize the fluid |

| Ram (Large Piston) | Multiplies the input force to create massive output |

| Hydraulic Accumulator | Stores pressurized fluid for powerful bursts of energy |

Ready to harness the power of hydraulic press technology for your laboratory or production needs?

At KINTEK, we specialize in providing robust and reliable lab equipment, including hydraulic press machines designed for precision and performance. Our solutions are engineered to deliver the immense, controlled force your applications demand, from material testing to sample preparation.

Contact our experts today to discuss how a KINTEK hydraulic press can enhance your efficiency and achieve superior results.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples