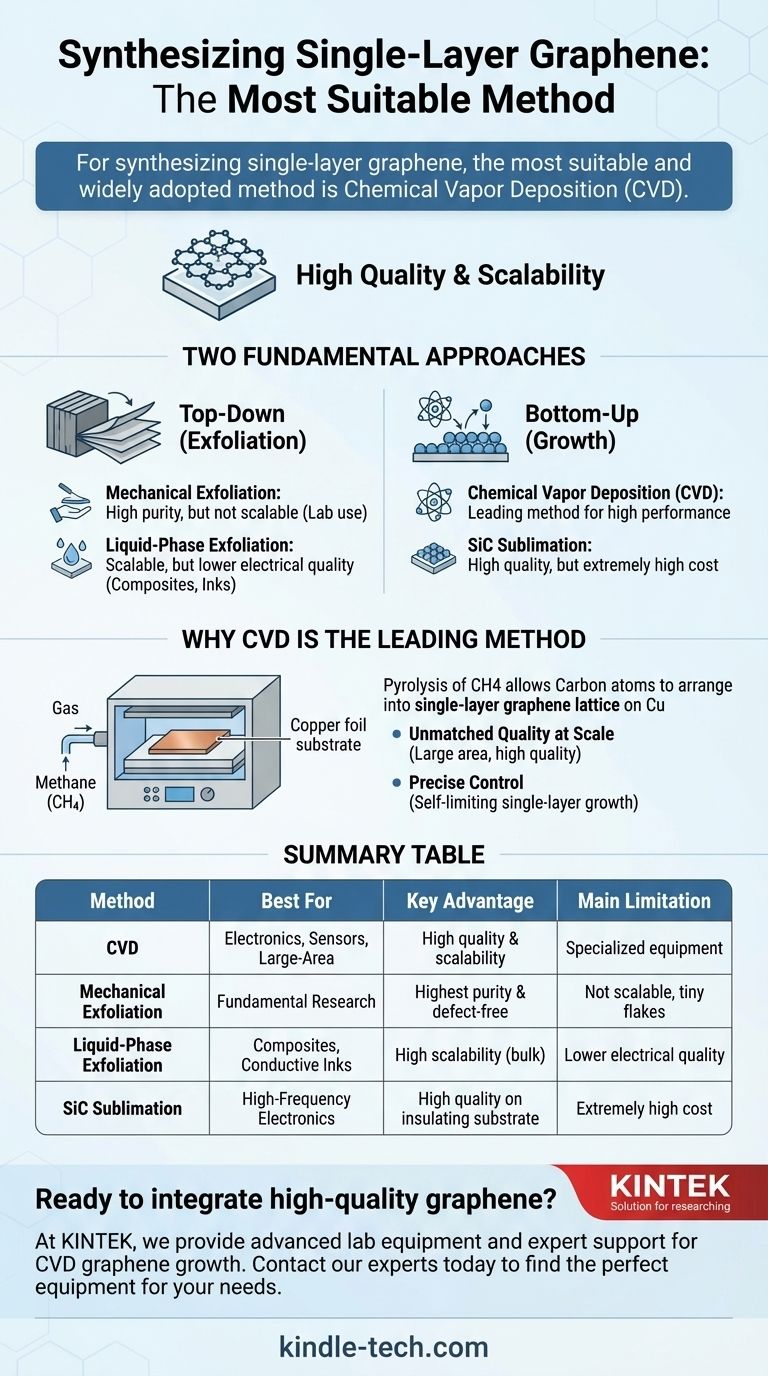

For synthesizing single-layer graphene, the most suitable and widely adopted method for producing high-quality material over large areas is Chemical Vapor Deposition (CVD). While other methods exist, CVD provides the best overall balance of quality, scalability, and control required for most electronics and research applications.

The ideal method for graphene synthesis is not a single answer but a choice dictated by your final goal. While mechanical exfoliation produces the highest-purity flakes for fundamental research, Chemical Vapor Deposition (CVD) is the most versatile and promising technique for creating the large, uniform, single-layer sheets needed for practical technology.

The Two Fundamental Approaches to Graphene Synthesis

Understanding graphene production begins with recognizing the two opposing strategies used to create it: starting big and going small ("top-down"), or starting small and building up ("bottom-up").

The "Top-Down" Approach (Exfoliation)

This method involves starting with a bulk material like graphite and separating it into progressively thinner layers until you isolate a single layer of graphene.

Mechanical exfoliation, famously known as the "Scotch tape method," peels layers from graphite. It yields pristine, high-quality flakes but is not scalable and is therefore limited to fundamental lab studies.

Liquid-phase exfoliation is a more scalable top-down method suitable for mass production. However, it often results in graphene with lower electrical quality and defects, making it better for applications like composites or inks rather than high-performance electronics.

The "Bottom-Up" Approach (Growth)

This strategy involves building the graphene lattice atom by atom on a substrate material. This approach offers superior control over the final product's quality and layer count.

This category includes methods like the sublimation of silicon carbide (SiC) and, most importantly, Chemical Vapor Deposition (CVD).

Why Chemical Vapor Deposition (CVD) is the Leading Method

For most applications demanding high performance, CVD has emerged as the industry standard. It uniquely combines the ability to produce high-quality graphene with the potential for large-scale manufacturing.

The Principle of CVD

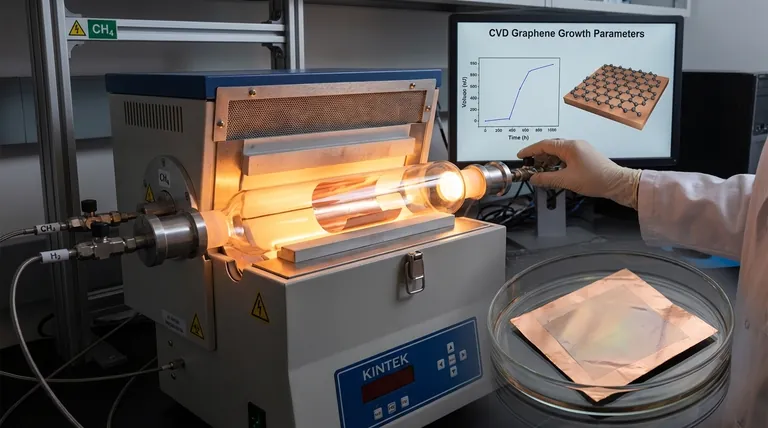

The CVD process involves heating a catalyst substrate, typically a copper (Cu) foil, inside a furnace. Carbon-containing gases, like methane (CH4), are then introduced.

Pyrolysis, the thermal decomposition of these gases, breaks them down and allows carbon atoms to arrange themselves into the hexagonal lattice of graphene on the surface of the copper foil.

Unmatched Quality at Scale

CVD is the most promising technique for producing high-quality graphene on large areas. This combination is critical for creating components like transparent conductive films, sensors, and next-generation electronic circuits.

Advanced variations, such as the vapor-trapping method, further refine the CVD process to grow exceptionally large, single-crystalline graphene grains, pushing the quality even higher.

Precise Control Over Single-Layer Growth

The self-limiting nature of graphene growth on copper foil makes CVD particularly effective for producing single layers. Once the copper surface is covered with one atomic layer of carbon, the catalytic process largely stops, preventing the formation of unwanted additional layers.

Understanding the Trade-offs

No single method is perfect for every scenario. The superiority of CVD becomes clear when you objectively compare the compromises required by other techniques.

Mechanical Exfoliation: Perfect but Impractical

This method produces the highest quality, defect-free graphene flakes. However, the process is manual, yields tiny flakes, and has zero scalability for any commercial application. It remains a tool for pure research.

Liquid-Phase Exfoliation: Scale Over Quality

This technique can produce large quantities of graphene dispersions, but the electrical properties of the material are significantly compromised compared to CVD-grown graphene. This trade-off makes it unsuitable for advanced electronics.

Sublimation of Silicon Carbide (SiC): High Cost for High Performance

Growing graphene by sublimating silicon from a SiC wafer produces extremely high-quality material directly on an insulating substrate, which is ideal for high-frequency electronics. However, the high cost of SiC wafers makes this method prohibitively expensive for most uses.

Selecting the Right Method for Your Application

Your final objective is the most important factor in choosing a synthesis method.

- If your primary focus is fundamental physics research on pristine flakes: Mechanical exfoliation provides the highest-quality samples for laboratory measurements.

- If your primary focus is creating high-quality, large-area films for electronics, photonics, or sensors: Chemical Vapor Deposition (CVD) is the established and most suitable method.

- If your primary focus is bulk production for composites, coatings, or conductive inks: Liquid-phase exfoliation offers the best scalability, provided that pristine electrical quality is not a requirement.

Ultimately, choosing the right synthesis technique is about aligning the method's strengths with your specific application's demands.

Summary Table:

| Method | Best For | Key Advantage | Main Limitation |

|---|---|---|---|

| Chemical Vapor Deposition (CVD) | Electronics, Sensors, Large-Area Films | High quality & scalability | Requires specialized equipment |

| Mechanical Exfoliation | Fundamental Research | Highest purity & defect-free flakes | Not scalable; tiny flakes |

| Liquid-Phase Exfoliation | Composites, Conductive Inks | High scalability for bulk production | Lower electrical quality |

| SiC Sublimation | High-Frequency Electronics | High quality on insulating substrate | Extremely high cost |

Ready to integrate high-quality graphene into your research or product development?

At KINTEK, we specialize in providing the advanced lab equipment and expert support needed for cutting-edge material synthesis like CVD graphene growth. Our solutions are designed to help researchers and engineers like you achieve precise, reproducible results.

Let's discuss how we can support your project:

Contact our experts today to find the perfect equipment for your laboratory's needs.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision