At its core, compression molding is important because it is an unparalleled method for creating exceptionally strong, durable, and dimensionally stable parts. This process excels where others falter, particularly when working with high-performance thermoset plastics and composite materials that require immense pressure and heat to achieve their final properties. Its ability to produce large, robust components with varying wall thicknesses makes it essential for demanding industrial, automotive, and electrical applications.

The true value of compression molding isn't speed, but strength. It is the go-to process when the structural integrity and durability of a component are non-negotiable, especially for materials that cannot be processed using higher-volume methods like injection molding.

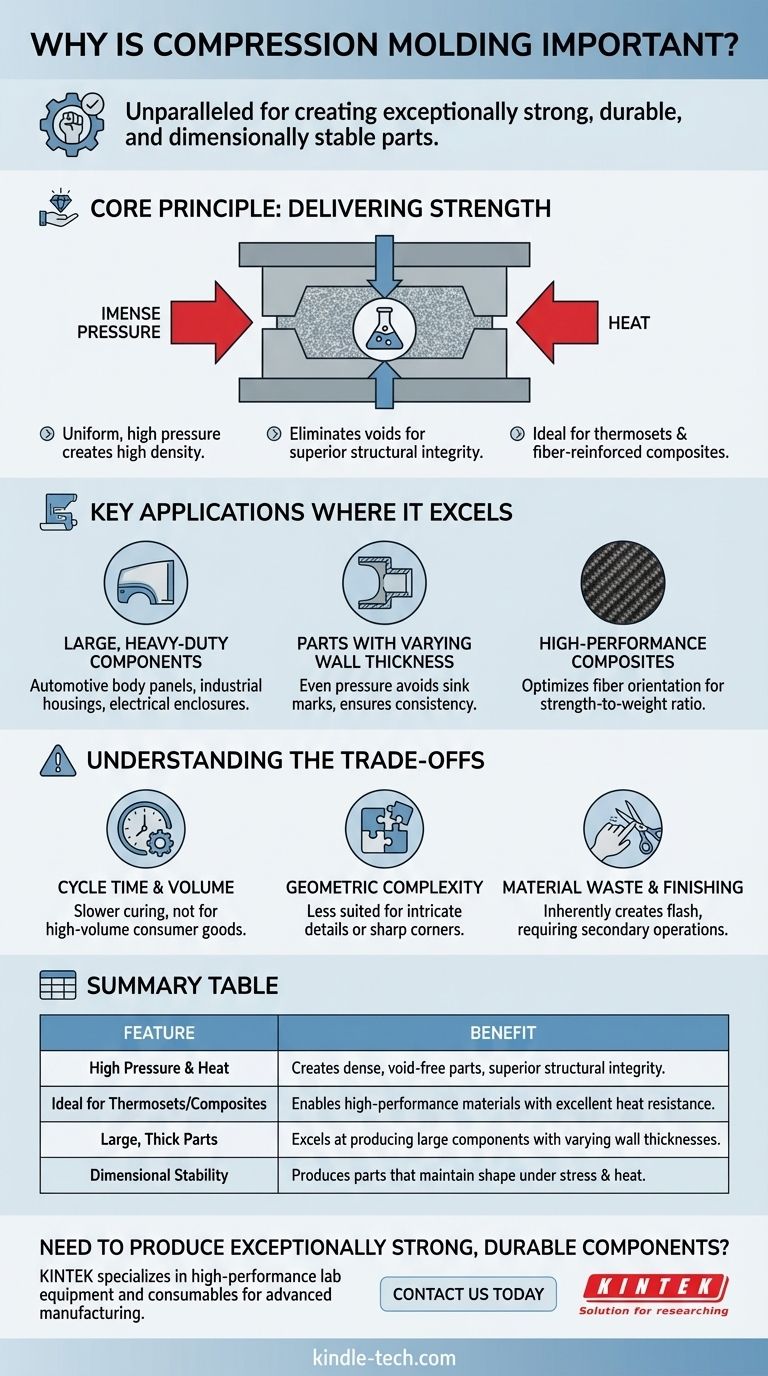

The Core Principle: How Compression Molding Delivers Strength

Compression molding operates on a straightforward yet powerful principle: applying immense pressure and heat to a material charge within a mold cavity. This forces the material to conform to the shape of the mold while initiating a chemical reaction (curing).

The Process in Brief

First, a precise amount of molding material, often pre-formed into a "charge," is placed into the open, heated lower half of a mold. The top half of the mold then closes, applying extreme pressure (often hundreds of tons) to the material. This pressure, combined with the heat, forces the material to fill every part of the mold cavity and initiates the curing process that permanently sets its shape.

High Pressure Creates High Density

The defining feature of this process is the application of uniform, high pressure. This pressure ensures the material is densely packed, eliminating voids or air pockets and resulting in a component with superior structural integrity and mechanical strength. The final product is robust, solid, and highly resistant to impact and wear.

Ideal for Thermosets and Composites

Compression molding is uniquely suited for thermoset plastics and fiber-reinforced composites. Unlike thermoplastics (used in injection molding), which can be re-melted, thermosets undergo an irreversible chemical change when cured. This process is the perfect environment to manage that transformation, resulting in parts with high heat resistance and dimensional stability.

Key Applications Where Compression Molding Excels

The unique advantages of compression molding make it the only logical choice for a specific class of industrial components.

Large, Heavy-Duty Components

Because the process doesn't rely on injecting material through small gates, it is highly effective for producing very large and thick parts. This includes automotive body panels, heavy-duty electrical enclosures, and large industrial equipment housings where strength is the primary design driver.

Parts with Varying Wall Thickness

Injection molding often struggles with thick sections, which can lead to cosmetic defects like sink marks. Compression molding's even application of pressure across the entire part surface allows it to produce components with significant variations in wall thickness without compromising structural or aesthetic quality.

High-Performance Composites

For materials like fiberglass or carbon fiber reinforced plastics, compression molding is essential. The process ensures the reinforcing fibers are properly wetted by the resin matrix and oriented correctly, maximizing the strength-to-weight ratio of the final composite part.

Understanding the Trade-offs

No manufacturing process is perfect for every application. Understanding the limitations of compression molding is crucial for making an informed decision.

Cycle Time and Volume

The curing process for thermoset materials takes time, typically several minutes per part. This makes compression molding significantly slower than injection molding, which can produce parts in seconds. Therefore, it is generally not suitable for very high-volume, low-cost consumer products.

Geometric Complexity

While excellent for large, robust forms, compression molding can be less suited for producing parts with extremely intricate details, sharp internal corners, or complex features like snap-fits. The flow of the material under pressure is less dynamic than in injection molding.

Material Waste and Finishing

The process inherently creates "flash"—excess material that is squeezed out between the two halves of the mold. This flash must be trimmed in a secondary operation, which adds labor, cost, and creates material waste.

Making the Right Choice for Your Goal

Selecting a manufacturing process requires aligning its capabilities with your project's most critical requirements.

- If your primary focus is ultimate strength and durability with thermosets or composites: Compression molding is the definitive choice for creating robust, long-lasting parts.

- If your primary focus is producing large, thick-walled components without cosmetic defects: Compression molding offers a clear advantage over processes prone to sink and voids.

- If your primary focus is high-volume, low-cost production of complex thermoplastic parts: Injection molding is almost certainly the more efficient and economical solution.

Choosing the right process begins with understanding that each one is a specialized tool designed to solve a specific engineering problem.

Summary Table:

| Feature | Benefit |

|---|---|

| High Pressure & Heat | Creates dense, void-free parts with superior structural integrity. |

| Ideal for Thermosets/Composites | Enables use of high-performance materials with excellent heat resistance. |

| Large, Thick Parts | Excels at producing large components with varying wall thicknesses. |

| Dimensional Stability | Produces parts that maintain their shape and size under stress and heat. |

Need to produce exceptionally strong, durable components?

At KINTEK, we specialize in providing the high-performance lab equipment and consumables necessary for advanced manufacturing processes like compression molding. Whether you're developing new composite materials or optimizing production for automotive or industrial applications, our solutions help you achieve superior part quality and reliability.

Contact us today to discuss how KINTEK can support your laboratory's specific needs and help you build stronger, better products.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- How much does it cost to make a mold? A Strategic Guide to Injection Mold Pricing

- What measurement methods are commonly used for powder samples in infrared spectroscopy? Optimize Your FTIR Analysis

- What are the applications of moulding process? Powering Mass Production from Cars to Medical Devices

- What role does a graphite mold play in the hot-press sintering of ZrB2-SiC composites? Master Ultra-High Temp Sintering

- What role do metal molds play during the cold pressing stage of VC/Cu composite fabrication? High-Precision Shaping

- What roles do graphite molds play during the Spark Plasma Sintering (SPS) process? Optimize Your Nickel-Based Alloys

- Why are graphite molds necessary for ZrB2-SiC hot pressing? Unlock High-Performance Ceramic Sintering

- How does a 3 plate Mould work? A Guide to Advanced Injection Molding for Complex Parts