In vacuum-dependent processes, precision and control are not optional features; they are the foundation of success. Maintaining a specific, stable vacuum level is critical for ensuring the quality and consistency of the final product, the repeatability of the manufacturing process, and the integrity of scientific data.

The core issue is that a vacuum is not simply an empty space—it is an active and critical process parameter. Fluctuation in vacuum is a primary source of process failure, leading to inconsistent results, damaged products, and unreliable research.

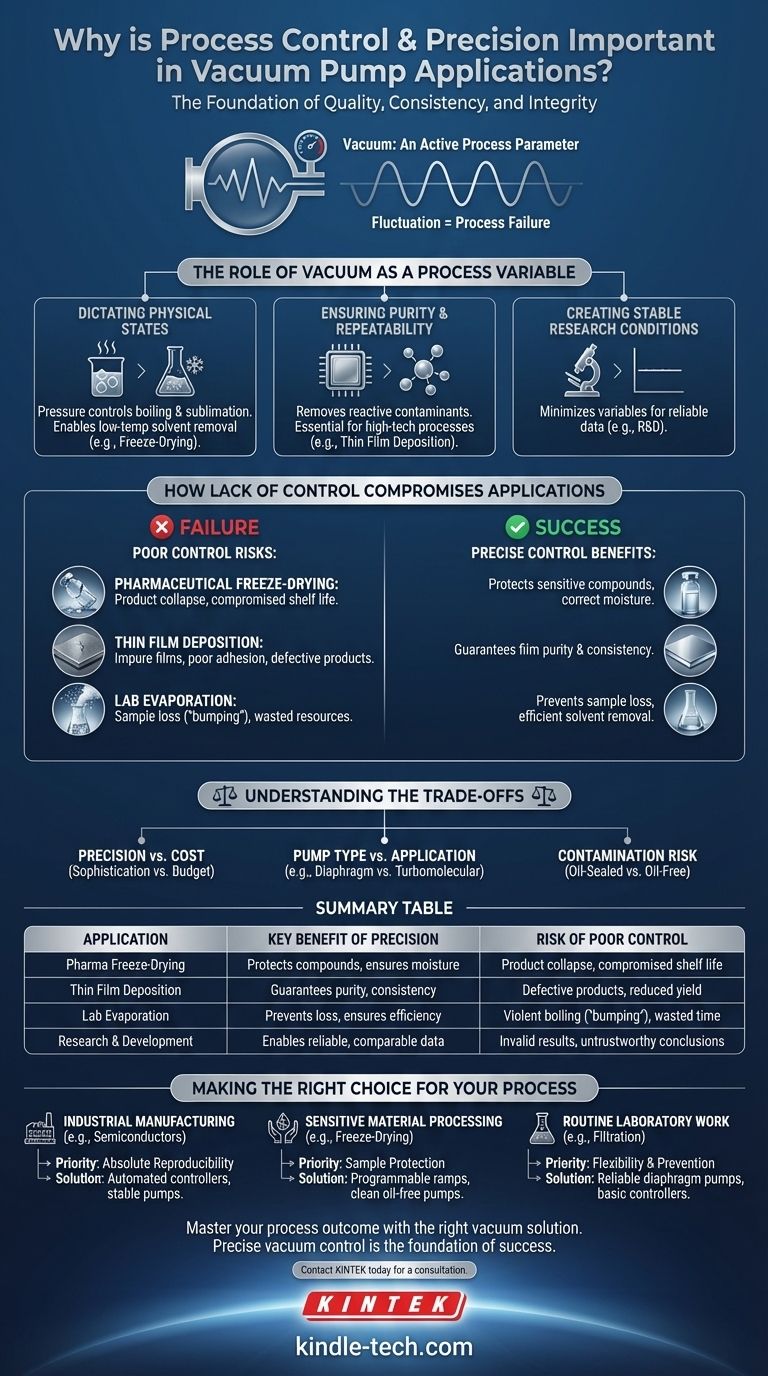

The Role of Vacuum as a Process Variable

Understanding why precision matters requires seeing vacuum not as a passive state but as an active tool that directly influences physical and chemical behaviors.

Controlling Pressure to Dictate Physical States

Just as temperature determines whether water is ice, liquid, or steam, pressure dictates the boiling point of liquids and the sublimation point of solids.

In applications like freeze-drying or evaporation, precise vacuum control allows you to remove solvents at low temperatures, protecting sensitive biological or pharmaceutical compounds from heat damage.

Ensuring Purity and Repeatability

Many high-tech processes, such as semiconductor manufacturing or thin film deposition, must occur in an environment free of reactive molecules like oxygen and water vapor.

A stable, controlled vacuum ensures that these contaminants are removed and kept out, guaranteeing that each production run has the same starting conditions and produces a consistent, high-purity result.

Creating Stable Conditions for Research

In a research and development setting, the goal is to produce reliable and comparable data. An uncontrolled or fluctuating vacuum is an unmanaged variable that invalidates experimental results.

Precise control ensures that the only things changing in an experiment are the variables you are intentionally testing, leading to trustworthy conclusions.

How Lack of Control Compromises Applications

When vacuum control is poor, the consequences are direct and tangible, often leading to complete process failure.

In Pharmaceutical Freeze-Drying

If the vacuum is too deep (pressure is too low) during the primary drying phase, it can cause the product's structure to collapse. If the vacuum is too shallow (pressure is too high), the drying process becomes inefficient and may leave behind residual moisture, compromising shelf life.

In Thin Film Deposition

For applications like coating optics or manufacturing microchips, inconsistent vacuum levels lead to impure films, poor adhesion to the substrate, and variations in thickness. This directly translates to defective products and reduced yields.

In General Laboratory Evaporation

When using a rotary evaporator, a vacuum that is too aggressive causes violent boiling, known as "bumping," which results in sample loss. A vacuum that is too weak dramatically slows down the process, wasting time and resources.

Understanding the Trade-offs

Achieving perfect vacuum control involves balancing performance, cost, and application-specific needs. There is no single solution that fits all scenarios.

Precision vs. Cost

Systems with highly sophisticated electronic controllers, sensors, and valves deliver exceptional precision but come at a significantly higher cost. For simple filtration, this is overkill. For semiconductor deposition, it is a necessity.

Pump Type vs. Application Need

The choice of pump is fundamental to control. An oil-free diaphragm pump is clean and ideal for many lab applications but cannot reach the ultra-high vacuum levels required for surface science. A turbomolecular pump can, but it is complex and expensive.

Contamination Risk

Pumps like oil-sealed rotary vane pumps can achieve deep vacuums cost-effectively but carry an inherent risk of oil vapor back-streaming into the chamber. This contamination can ruin sensitive samples or processes, making oil-free pumps a requirement in many fields.

Making the Right Choice for Your Process

The level of precision you need is dictated entirely by your end goal. Evaluate your application to determine the right level of investment in your vacuum system.

- If your primary focus is industrial manufacturing (e.g., thin films, semiconductors): Your priority is absolute reproducibility, so invest in automated process controllers and pumps designed for long-term stability.

- If your primary focus is sensitive material processing (e.g., freeze-drying): Your priority is protecting the sample, which demands systems with precise, programmable vacuum ramps and a clean, oil-free pump path.

- If your primary focus is routine laboratory work (e.g., evaporation, filtration): Your priority is flexibility and preventing sample loss, where a reliable diaphragm pump with a manual or basic electronic controller is often sufficient.

Mastering your vacuum level is the key to mastering your process outcome.

Summary Table:

| Application | Key Benefit of Precision Control | Risk of Poor Control |

|---|---|---|

| Pharmaceutical Freeze-Drying | Protects sensitive compounds, ensures correct moisture levels | Product collapse, compromised shelf life |

| Thin Film Deposition | Guarantees film purity, adhesion, and thickness consistency | Defective products, reduced manufacturing yield |

| Laboratory Evaporation | Prevents sample loss, ensures efficient solvent removal | Violent boiling ('bumping'), wasted time and resources |

| Research & Development | Enables reliable, comparable data by controlling variables | Invalid experimental results, untrustworthy conclusions |

Master your process outcome with the right vacuum solution.

Precise vacuum control is the foundation of success for your specific application, whether it's sensitive R&D, high-purity manufacturing, or efficient lab work. The consequences of poor control—from ruined products to invalid data—are too significant to leave to chance.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts understand the critical balance between performance, cost, and contamination risk. We can help you select the ideal vacuum pump and control system—from reliable diaphragm pumps for routine work to sophisticated, automated systems for high-stakes manufacturing—ensuring your process is built on a foundation of precision and reliability.

Don't let vacuum fluctuations compromise your work. Contact KINTEK today for a consultation and ensure your process integrity.

Visual Guide

Related Products

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the function of a laboratory blast drying oven in the curing process of hydrophobic membranes? Master Curing.

- What material is used for furnace lining? A Guide to Selecting the Right Refractory

- Why are high-precision temperature-controlled heating stages necessary for Ni-Cr alloys? Ensure Accurate RIS Results

- What is the function of a water-cooled copper sample holder? Ensure Thermal Stability in 500W RF Plasma Processes

- Why are zirconia grinding balls preferred for HE-O-MIEC mixing? Ensure Purity & Precision in Synthesis

- What is the annealing temperature of quartz? Achieve Optimal Thermal Stability for Your Components

- Where are vacuum switches used? Essential Safety and Control in Industrial and Automotive Systems

- Why are zirconia grinding balls preferred for ZrB2-SiC powders? Achieve High-Purity Ceramic Milling Results