In thin film deposition, a vacuum environment is non-negotiable. It is the foundational requirement for creating a high-quality, functional film. The vacuum serves two primary purposes: it eliminates atmospheric gases that would otherwise collide with and block the deposition material, and it removes reactive contaminants like oxygen and water vapor that would chemically ruin the film being created.

The core function of a vacuum in thin film deposition is to establish a controlled and pure environment. By removing virtually all other particles, a vacuum ensures the material being deposited can travel directly to the target and that the final film is not compromised by unwanted chemical reactions.

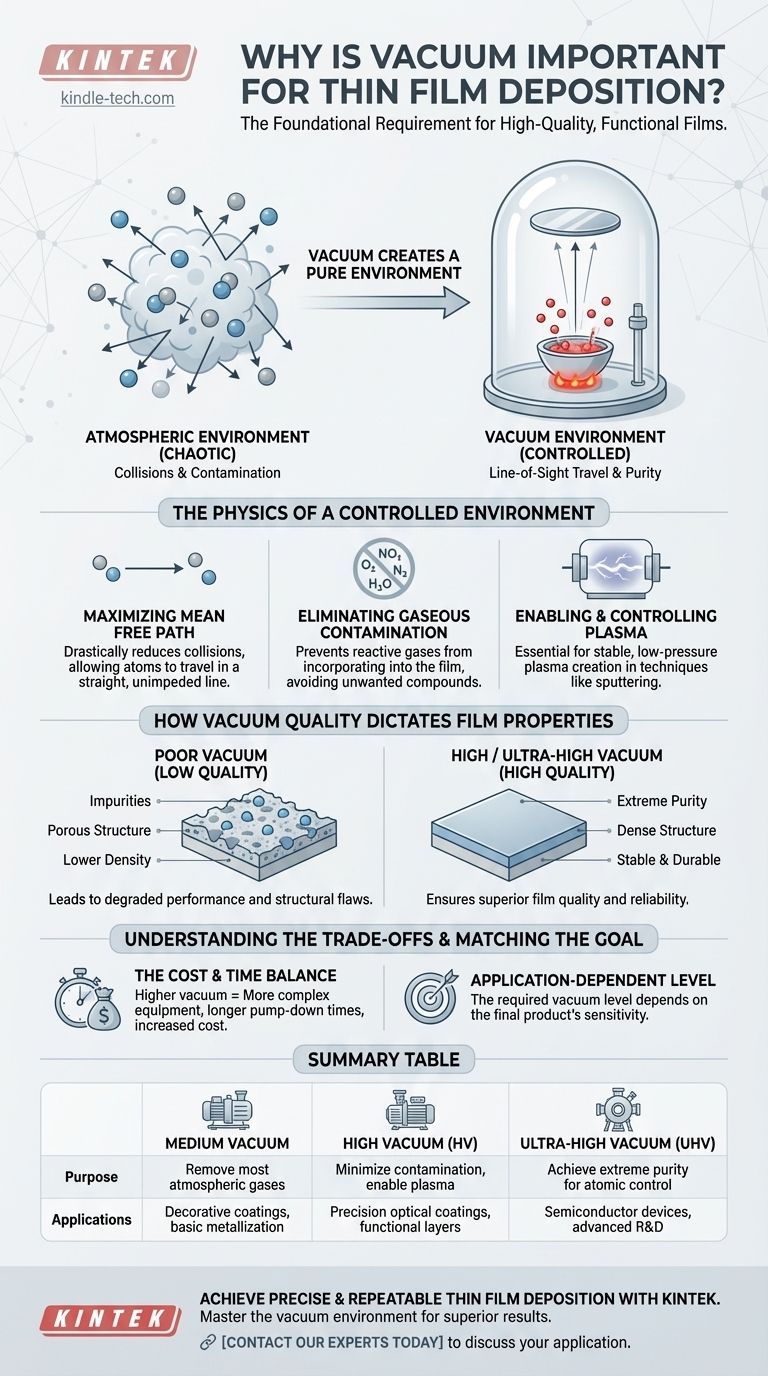

The Physics of a Controlled Environment

To understand why vacuum is so critical, we need to examine the problems it solves on a molecular level. An atmospheric environment is a chaotic, dense sea of particles that is fundamentally hostile to the precision required for building a film one atomic layer at a time.

Maximizing the Mean Free Path

The mean free path is the average distance a particle can travel before it collides with another particle. In the atmosphere you are in now, that distance is incredibly short—only about 68 nanometers.

A deposition particle traveling from a source to a substrate in open air would suffer millions of collisions, scattering it and preventing it from ever reaching its target in a straight line.

By creating a vacuum, we drastically reduce the number of air molecules in the chamber. This increases the mean free path from nanometers to many meters, allowing the deposition atoms to travel in a straight, unimpeded line from the source to the substrate. This is known as line-of-sight travel and is essential for uniform coating.

Eliminating Gaseous Contamination

Atmospheric air is composed of highly reactive gases, primarily nitrogen, oxygen, and water vapor. If these molecules are present during deposition, they will readily incorporate themselves into the growing film.

This contamination creates unintended chemical compounds, such as oxides and nitrides. These impurities can catastrophically alter the film's desired properties, whether they are optical, electrical, or mechanical. For example, an unwanted oxide layer in a semiconductor film can ruin its conductive properties.

Enabling and Controlling Plasma

Many modern deposition techniques, such as sputtering, rely on the creation of a plasma to function. A plasma is a controlled, ionized gas (often Argon) that is used to eject material from a target.

It is impossible to generate and sustain a stable, low-pressure process plasma in an atmospheric environment. A vacuum chamber is necessary first to remove the atmospheric gases and then to introduce a very small, precise amount of the desired process gas. The vacuum level gives an operator precise control over the plasma's density, pressure, and energy.

How Vacuum Quality Dictates Film Properties

The quality of the final film is directly proportional to the quality of the vacuum. A "poor" vacuum versus a "high" or "ultra-high" vacuum can be the difference between a functional device and a complete failure.

The Impact on Film Purity

The level of vacuum determines the purity of the deposited film. In a lower-quality vacuum, more residual gas molecules (like water) will be present. These molecules will be incorporated as impurities, degrading performance.

For applications like semiconductor manufacturing or precision optics, an ultra-high vacuum (UHV) is often required to achieve the extreme purity necessary for the device to function correctly.

The Influence on Film Structure

The presence of residual gas molecules doesn't just impact purity; it also affects the physical structure of the film. Collisions between deposition atoms and gas molecules reduce the energy of the arriving atoms.

This lower energy can result in a film that is less dense, more porous, and has higher internal stress. A clean, high-vacuum environment ensures atoms arrive at the substrate with the intended energy, promoting the growth of a dense, stable, and durable film structure.

Understanding the Trade-offs

While a better vacuum generally leads to a better film, achieving it involves practical and economic compromises.

Higher Vacuum vs. Higher Cost and Time

Reaching higher vacuum levels requires more sophisticated and expensive equipment, such as turbomolecular or cryogenic pumps.

Furthermore, the time it takes to remove more and more molecules from the chamber—known as the "pump-down time"—increases exponentially. For industrial-scale production, a balance must be struck between the required film quality and the throughput of the coating system.

Process Gas vs. Residual Gas

In processes like sputtering or chemical vapor deposition (CVD), a specific process gas is intentionally introduced into the vacuum chamber. The goal is to have the chamber's environment dominated by this controlled gas, not by unwanted residual atmospheric gases.

The vacuum system's primary job is to remove the "bad" gases (air, water) so the "good" gas (e.g., Argon) can perform its function cleanly and predictably.

Matching the Vacuum to Your Goal

The necessary level of vacuum is entirely dependent on the application of the thin film.

- If your primary focus is decorative coatings: A lower-quality vacuum may be acceptable, as minor impurities are unlikely to affect the aesthetic appearance.

- If your primary focus is precision optical coatings: A high vacuum is critical to prevent contamination that would cause the film to absorb or scatter light, degrading optical performance.

- If your primary focus is semiconductor devices: An ultra-high vacuum (UHV) is often mandatory to achieve the extreme purity required for reliable electronic properties.

Ultimately, mastering the vacuum environment is the key to controlling the quality, performance, and repeatability of your deposited thin films.

Summary Table:

| Vacuum Level | Key Purpose | Typical Applications |

|---|---|---|

| Medium Vacuum | Remove most atmospheric gases | Decorative coatings, basic metallization |

| High Vacuum (HV) | Minimize contamination, enable plasma processes | Precision optical coatings, functional layers |

| Ultra-High Vacuum (UHV) | Achieve extreme purity for atomic-level control | Semiconductor devices, advanced R&D |

Achieve Precise and Repeatable Thin Film Deposition with KINTEK

Mastering the vacuum environment is the foundation of successful thin film coating. Whether you are developing semiconductors, precision optics, or functional coatings, the right equipment is critical for controlling purity, structure, and performance.

KINTEK specializes in high-quality lab equipment and consumables for all your vacuum and deposition needs. Our expertise ensures you have the reliable tools necessary to achieve superior results in your laboratory.

Ready to optimize your thin film process? Contact our experts today to discuss your specific application and discover how KINTEK solutions can enhance your research and production.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition