To put it simply, a vacuum is essential for sputter coating because it achieves two critical goals that are impossible in normal atmospheric conditions. First, it removes unwanted gases like oxygen and water vapor that would contaminate the coating and ruin its properties. Second, it creates a controlled, low-pressure environment that allows coating atoms to travel from their source to the substrate without being scattered or blocked.

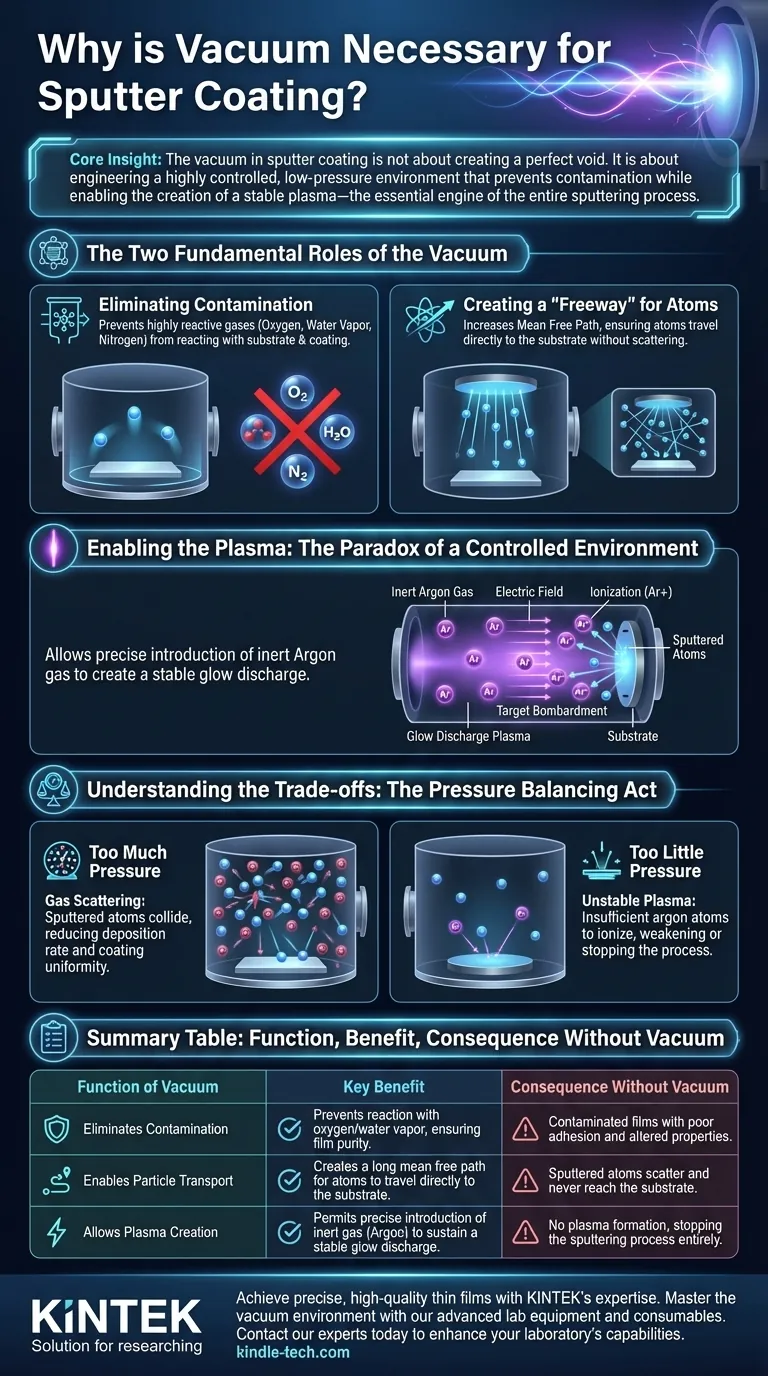

The core insight is that the vacuum in sputter coating is not about creating a perfect void. It is about engineering a highly controlled, low-pressure environment that prevents contamination while enabling the creation of a stable plasma—the essential engine of the entire sputtering process.

The Two Fundamental Roles of the Vacuum

To understand why sputter coating is unachievable without a vacuum, we must break down its dual functions: creating a pure environment and enabling efficient particle transport.

Eliminating Contamination

The air we breathe is a mixture of highly reactive gases, primarily nitrogen, oxygen, and water vapor.

If these molecules were present during the coating process, they would aggressively react with both the substrate surface and the sputtered coating material.

This reaction would create unwanted oxides and nitrides within the thin film, fundamentally altering its intended physical, optical, and electrical properties and leading to poor adhesion and performance. A vacuum chamber removes these contaminants to a negligible level.

Creating a "Freeway" for Atoms

Once an atom is ejected from the sputtering target, it must travel a significant distance to land on the substrate.

At atmospheric pressure, the sheer density of air molecules would make this journey impossible. The ejected atom would immediately collide with air molecules, lose its energy, and scatter in a random direction, never reaching its destination.

Creating a vacuum is like clearing all the traffic off a freeway. It dramatically increases the mean free path—the average distance a particle can travel before colliding with another—ensuring the sputtered atoms have a clear, straight-line path to the substrate.

Enabling the Plasma: The Paradox of a Controlled Environment

After creating a high vacuum to remove contaminants, the chamber is not left empty. Instead, it is backfilled with a small, precise amount of an inert gas, almost always argon. The vacuum is what allows this precise control.

Why an Inert Gas is Necessary

Argon gas acts as the medium for creating plasma. Because it is inert, it will not chemically react with the target material or the substrate.

Its purpose is to be ionized—stripped of an electron—by a strong electric field within the chamber.

The Glow Discharge (Plasma)

These newly created positive argon ions are accelerated by the electric field and slammed into the negatively charged source material, known as the target.

This high-energy bombardment is what physically knocks off, or "sputters," the atoms of the target material, which then travel through the vacuum to coat the substrate. This sustained process is known as a glow discharge plasma.

Understanding the Trade-offs: The Pressure Balancing Act

The level of vacuum, or more accurately the operating pressure of the argon gas, is not a single setting but a critical balancing act. The entire process fails if the pressure is either too high or too low.

The Problem with Too Much Pressure

If the argon pressure is too high, the vacuum chamber becomes "crowded."

The atoms sputtered from the target will collide with too many argon gas atoms on their way to the substrate.

This gas scattering reduces the deposition rate, harms the uniformity of the coating, and can result in lower-density films with less desirable properties.

The Problem with Too Little Pressure

If the argon pressure is too low, there are not enough gas atoms available in the chamber to sustain a stable plasma.

Without a sufficient number of argon atoms to ionize, the bombardment of the target will weaken or stop altogether. This effectively shuts down the sputtering process.

Making the Right Choice for Your Goal

Controlling the vacuum level directly controls the final properties of your thin film. The optimal pressure depends entirely on the desired outcome of the coating process.

- If your primary focus is creating a high-purity, dense film: You need a high base vacuum to remove contaminants and then operate at the lowest possible argon pressure that still sustains a stable plasma.

- If your primary focus is maximizing deposition rate: You must find the operational "sweet spot" where the argon pressure is high enough to generate a dense, efficient plasma but not so high that gas scattering begins to significantly impede the coating process.

Ultimately, mastering the vacuum is mastering the control you have over the final properties of your thin film.

Summary Table:

| Function of Vacuum | Key Benefit | Consequence Without Vacuum |

|---|---|---|

| Eliminates Contamination | Prevents reaction with oxygen/water vapor, ensuring film purity. | Contaminated films with poor adhesion and altered properties. |

| Enables Particle Transport | Creates a long mean free path for atoms to travel directly to the substrate. | Sputtered atoms scatter and never reach the substrate. |

| Allows Plasma Creation | Permits precise introduction of inert gas (Argon) to sustain a stable glow discharge. | No plasma formation, stopping the sputtering process entirely. |

Achieve precise, high-quality thin films with KINTEK's expertise.

Mastering the vacuum environment is critical for successful sputter coating. Whether your goal is maximum film purity, high deposition rates, or specific film properties, the right equipment and process knowledge make all the difference.

KINTEK specializes in advanced lab equipment and consumables for all your coating and research needs. Our team can help you select the perfect sputter coating solution to ensure optimal vacuum control and process parameters for your specific application.

Contact our experts today to discuss how we can enhance your laboratory's capabilities and help you achieve flawless results.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Evaporation Boat for Organic Matter

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

People Also Ask

- How does concentration affect IR? Master Quantitative Analysis and Spectral Interpretation

- What is the composition of plastic pyrolysis product? A Breakdown of Oil, Gas, and Char Outputs

- What are three biomass materials that are pelletized? Wood, Agricultural Waste & Energy Crops

- What are the five methods of synthesis of nanoparticles? A Guide to Top-Down & Bottom-Up Approaches

- What is the difference between pyrolysis and incinerator? Unlock Waste's Potential vs. Destroy It

- Why is RF sputtering often used for oxide film deposition? Achieve Superior Insulating Film Quality

- Importance of Timing and Temperature in MFC Drying? Optimize Your Phosphorylated Cellulose Process Today

- What is a sputtering system? Achieve Unmatched Thin Film Deposition for Your Lab