At the heart of the modern metal industry, the press machine stands as the indispensable tool for shaping metal with unparalleled efficiency and consistency. Its importance stems from its ability to apply immense, controlled force to cut, bend, and form metal stock into finished parts, enabling the mass production of everything from automotive body panels to tiny electronic components.

The core importance of a press machine is its capacity for transformation, not removal. While other tools cut away material to create a shape, a press reshapes the material itself in a single, powerful stroke, making it the unrivaled engine of high-volume, cost-effective manufacturing.

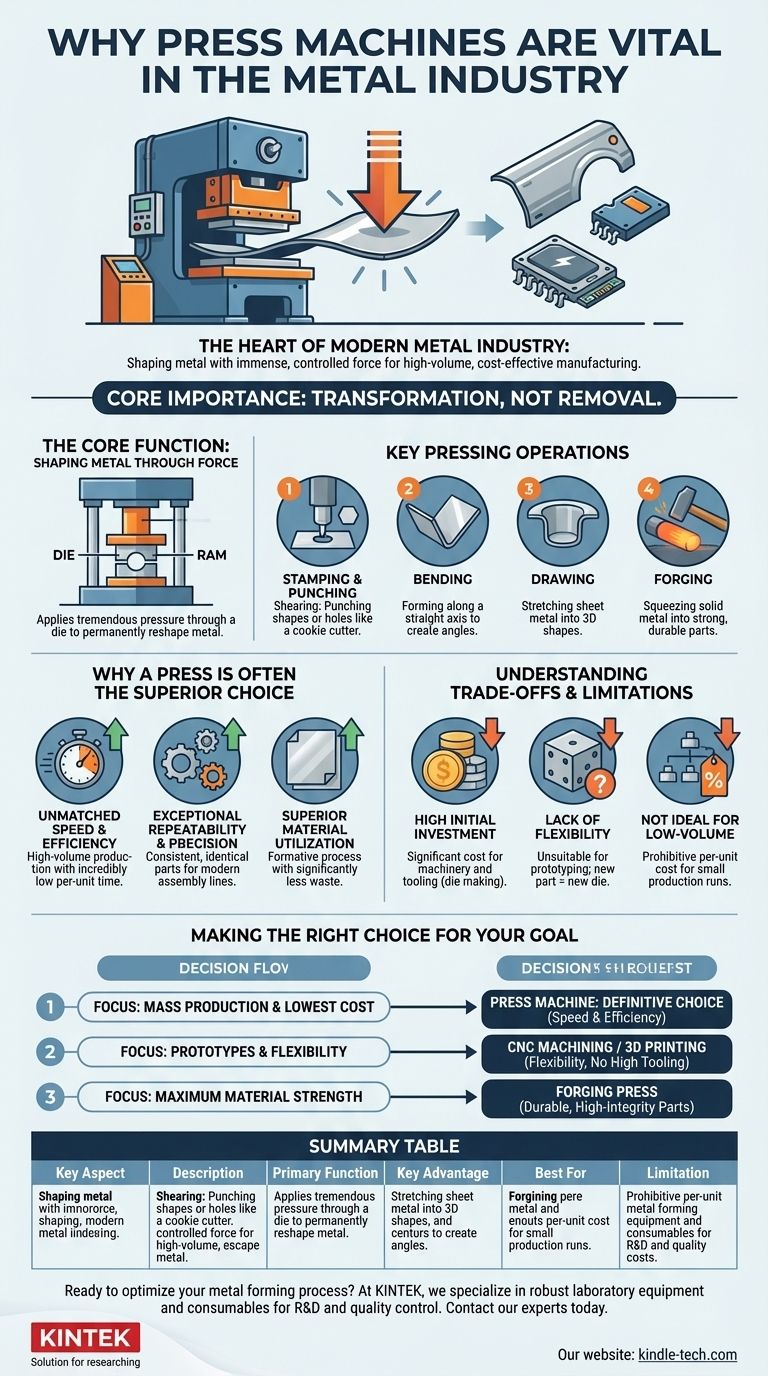

The Core Function: Shaping Metal Through Force

A press machine's role is simple in principle but vast in application. It works by applying tremendous pressure through a tool, known as a die, to a piece of metal, forcing it to take on a new shape permanently.

What is a Press Machine?

In its most basic form, a press consists of a stationary bed and a reciprocating ram or slide. A custom-made die set, with one half mounted to the bed and the other to the ram, acts as the mold. When the ram moves, it presses the metal workpiece between the two halves of the die, shaping it.

Key Pressing Operations

The versatility of a press comes from the different operations it can perform, which are determined by the design of the die.

-

Stamping and Punching: This is a shearing process. A stamping press acts like a highly precise and powerful cookie cutter, punching specific shapes out of a metal sheet or creating holes in a workpiece.

-

Bending: This involves forming the metal along a straight axis to create angles, such as the folds in a computer case or a metal bracket.

-

Drawing: This operation stretches sheet metal into a three-dimensional shape. It's how seamless items like kitchen sinks, pots, and automotive fuel tanks are formed from a flat piece of metal.

-

Forging: Instead of sheet metal, forging uses a solid block of metal (a billet). The press squeezes the heated metal into a die, aligning its internal grain structure and making the final part exceptionally strong and durable.

Why a Press is Often the Superior Choice

In manufacturing, the goal is to produce parts that meet specifications at the lowest possible cost and highest possible speed. The press machine excels in these areas.

Unmatched Speed and Efficiency

For high-volume production, no other method comes close to the speed of a press. Many presses can cycle hundreds or even thousands of times per minute, producing a finished part with each stroke. This makes the per-unit production time incredibly low.

Exceptional Repeatability and Precision

Once a die is made and the press is set up, it will produce virtually identical parts, one after another. This high degree of consistency is critical for modern assembly lines where components from different sources must fit together perfectly.

Superior Material Utilization

Processes like CNC machining are subtractive—they cut away material from a larger block, creating waste (chips). Pressing is a formative process that reshapes the existing material. This results in significantly less scrap, reducing material costs.

Understanding the Trade-offs and Limitations

Despite its advantages, the press machine is not the solution for every scenario. Understanding its limitations is key to making informed manufacturing decisions.

High Initial Investment

The primary barrier to entry is cost. Industrial presses are significant capital investments, but the real expense often lies in the tool and die making. Creating a high-quality, durable die for a specific part can be extremely expensive and time-consuming.

Lack of Flexibility

A die is engineered to produce a single, specific part. If the design of the part changes, even slightly, a completely new die must be created. This makes presses unsuitable for prototyping or custom, one-off jobs.

Not Ideal for Low-Volume Production

The high upfront cost of tooling means that presses are only cost-effective when the expense can be distributed over a very large number of units. For small production runs, the per-unit cost would be prohibitively high.

Making the Right Choice for Your Goal

The decision to use a press or another method depends entirely on the project's scale, complexity, and budget.

- If your primary focus is mass production and the lowest possible per-unit cost: A press machine is the definitive choice for its speed and efficiency.

- If your primary focus is creating complex prototypes or small batches with frequent design changes: CNC machining or 3D printing offers the necessary flexibility without high tooling costs.

- If your primary focus is achieving maximum material strength for a critical component: A forging press is the ideal solution for creating durable, high-integrity parts.

Ultimately, understanding the power and purpose of the press machine is to understand the very foundation of modern, efficient manufacturing.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Function | Applies immense force to cut, bend, and form metal (transformation, not removal). |

| Key Advantage | Unmatched speed and efficiency for high-volume production. |

| Best For | Mass production of consistent parts (e.g., automotive panels, electronic components). |

| Limitation | High initial tooling cost and lack of flexibility for prototyping. |

Ready to optimize your metal forming process?

At KINTEK, we specialize in providing robust laboratory equipment and consumables that support the research, development, and quality control behind efficient manufacturing. Whether you're testing material properties for a new stamped part or ensuring the quality of your metal stock, the right lab equipment is crucial.

Contact our experts today to discuss how KINTEK's solutions can enhance your R&D and quality assurance workflows, ensuring your manufacturing processes are built on a foundation of precision and reliability.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Double Plate Heating Press Mold for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How are hydraulics used in industry? Unlocking Immense Force for Heavy-Duty Applications

- How does axial pressure influence Al2O3-TiCN/Co-Ni ceramics? Optimize Densification and Microstructure

- Why is a laboratory hydraulic press required for boron carbide ceramic green bodies? Mastering Precise Pressure Loads

- What is the Bernoulli's principle of hydraulic press? It's Actually Pascal's Law That Powers It

- How many pounds of force can a hydraulic press produce? From 10,000 to 80,000+ Tons Explained

- How does a laboratory hydraulic press contribute to the formation of Ni-Al2O3-TiO2 green bodies? Expert Guide

- What is role of KBr in IR-spectroscopy? Create Transparent Pellets for Accurate Solid Sample Analysis

- How does temperature affect forging? Master Hot, Cold, and Warm Forging for Optimal Results