In short, sintering is necessary because compaction alone only creates a fragile, compressed powder shape with no functional strength. Sintering is the thermal process that transforms this "green" part into a solid, durable, and metallurgically bonded component by fusing the individual powder particles together.

While compaction gives a material its shape, it's the sintering process that provides the final strength, density, and structural integrity required for any engineering application. Without sintering, a compacted part is merely a weakly-held powder form, not a functional component.

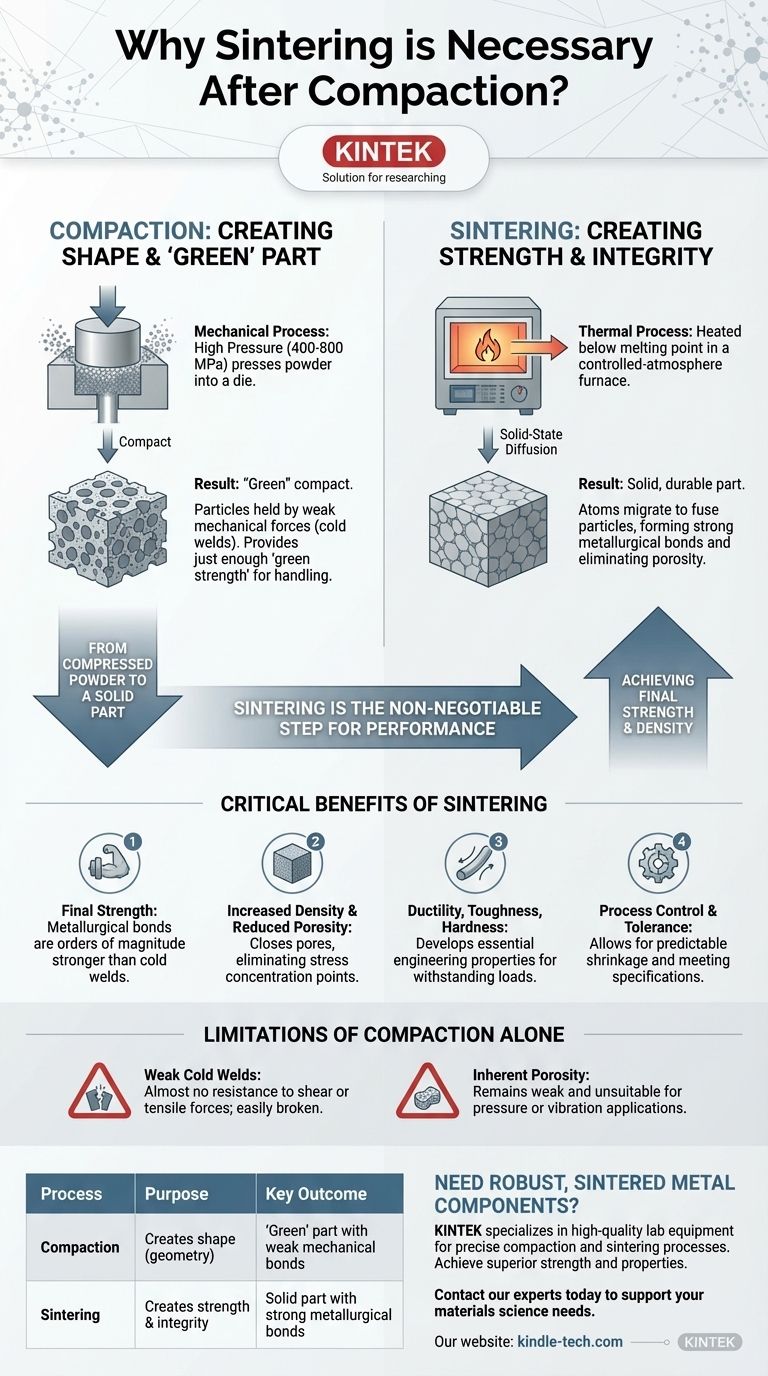

From Compressed Powder to a Solid Part

To understand the necessity of sintering, you must first recognize the distinct state of the material after each step in the powder metallurgy process. The two stages serve fundamentally different purposes.

The "Green" Part: The Result of Compaction

Compaction is a mechanical process. High pressure (often 400-800 MPa) is used to press metal powder in a die, forcing the particles into close contact.

This creates what is known as a "green" compact. The particles are held together by weak mechanical forces, primarily cold welds at their contact points.

This provides just enough "green strength" for the part to be handled and transported to the sintering furnace without crumbling. However, it possesses none of the strength, ductility, or toughness of a solid metal part.

The Sintering Transformation: Creating Metallurgical Bonds

Sintering is a thermal process. The green compact is heated in a controlled-atmosphere furnace to a temperature below the material's melting point.

At this high temperature, a process called solid-state diffusion begins. Atoms migrate across the boundaries of the individual particles, causing them to fuse together.

This diffusion creates strong metallurgical bonds, forming "necks" that grow at the particle contact points. The individual particles essentially merge, creating a solid, coherent mass with a dramatically reduced internal pore network.

Why Sintering is Non-Negotiable for Performance

A green part is unusable for any real-world application. Sintering is the step that imparts the essential properties that define a functional metal component.

Achieving Final Strength and Density

The primary purpose of sintering is to create strength. The metallurgical bonds formed during the process are orders of magnitude stronger than the cold welds from compaction.

This process also further densifies the part, closing many of the pores left after compaction. Eliminating this porosity is critical, as pores are stress concentration points and inherent weaknesses in the material structure.

Developing Essential Material Properties

Beyond simple strength, sintering develops other crucial engineering properties like ductility, toughness, and hardness. A green part is brittle and will fracture with minimal force. A sintered part can withstand mechanical loads, deformation, and impact.

Understanding the Key Limitations

Relying on compaction alone is not a viable manufacturing strategy due to its fundamental physical limitations.

The Weakness of Cold Welds

Compaction only creates physical contact and weak mechanical interlocking. These bonds have almost no resistance to shear or tensile forces. A green part can often be broken apart by hand.

Inherent Porosity

Even with extreme pressure, compaction always leaves a network of pores between particles. This porosity makes the component weak and unsuitable for applications where it might be exposed to pressure, vibration, or any significant load.

The Necessity of Process Control

Sintering is a highly controlled process. The temperature, time, and furnace atmosphere must be precisely managed to prevent oxidation and ensure the desired amount of diffusion occurs. This control is what allows for predictable shrinkage and ensures the final part meets its required dimensional tolerances and performance specifications.

Applying This Understanding to Your Goal

The two-step process is a symbiotic relationship where each stage performs a task the other cannot.

- If your primary focus is part geometry and initial shape: Compaction is the critical step for defining the component's net-shape, complexity, and initial density before the final properties are developed.

- If your primary focus is mechanical performance and final integrity: Sintering is the essential step for transforming the powder form into a strong, durable, and functional engineering material ready for its application.

Ultimately, compaction gives a material its shape, but sintering is what gives it its strength and utility as a solid, finished part.

Summary Table:

| Process | Purpose | Key Outcome |

|---|---|---|

| Compaction | Creates shape (geometry) | 'Green' part with weak mechanical bonds |

| Sintering | Creates strength & integrity | Solid part with strong metallurgical bonds |

Need robust, sintered metal components for your laboratory or production line?

KINTEK specializes in providing the high-quality lab equipment and consumables necessary for precise compaction and sintering processes. Our expertise ensures you achieve the superior strength, density, and material properties required for your engineering applications.

Contact our experts today to discuss how we can support your powder metallurgy and materials science needs.

Visual Guide

Related Products

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What is the purpose of the arc furnace? Enabling Flexible, Efficient Metal Recycling and Steel Production

- What is the heating rate during heat treatment? Master the Key to Material Integrity

- What are the three types of furnaces? Choose the Right Furnace for Your Needs

- Why is vacuum created in the chamber before thermal evaporation? For High-Quality, Uniform Thin Films

- What metals are used in sintering? From Common Steels to High-Performance Alloys

- What is the working principle of vacuum brazing furnace? Achieve Ultra-Clean, High-Strength Metal Joining

- What is sinter-HIP? Achieve Full Density and Superior Performance for Critical Components

- Can aluminum be brazed? Mastering the Oxide Layer for Strong Joints