In short, thin film deposition requires a vacuum to solve two fundamental problems: collisions and contamination. By removing the vast majority of air molecules from a chamber, we create a controlled environment that allows deposition material to travel unimpeded to its target and prevents unwanted chemical reactions that would otherwise ruin the film's properties.

The core purpose of a vacuum in thin film deposition is to create a "clean highway" for material to travel from a source to a substrate. Without it, the process would be like trying to spray paint in a hurricane, resulting in a contaminated, non-uniform, and functionally useless film.

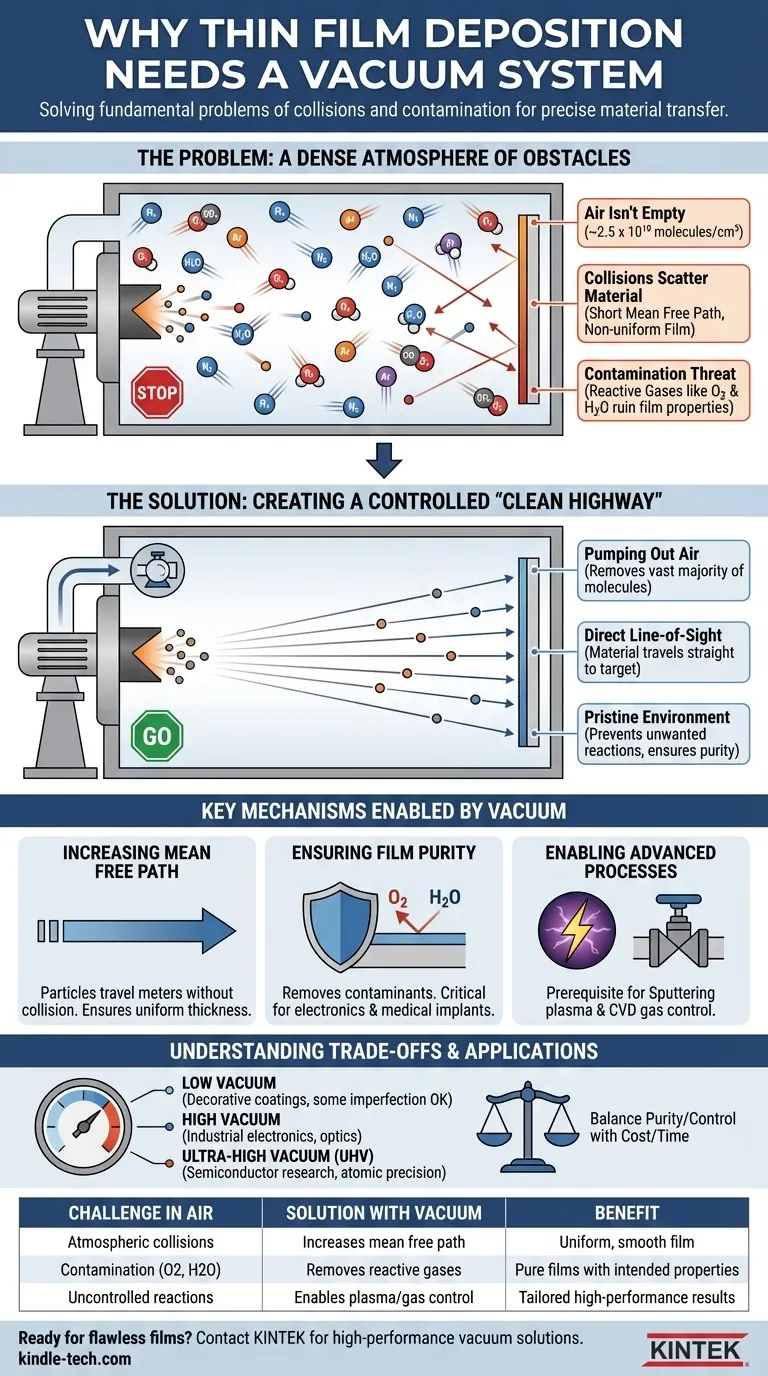

The Problem: An Atmosphere Full of Obstacles

To understand why a vacuum is non-negotiable, you must first recognize that the air around us is not empty. It's a dense sea of particles that are hostile to the precision required for creating thin films.

Air Isn't Empty

Standard atmospheric pressure is the result of countless molecules—primarily nitrogen, oxygen, water vapor, argon, and carbon dioxide—constantly moving and colliding. At this pressure, there are roughly 2.5 x 10¹⁹ molecules in every cubic centimeter.

The Impact of Collisions

In deposition processes like sputtering or evaporation, atoms or molecules of a source material are ejected towards a substrate. In a normal atmosphere, these ejected particles would collide with air molecules within micrometers of leaving their source.

These collisions scatter the deposition material, preventing it from reaching the substrate in a straight, predictable line. This makes it impossible to create a uniform, smooth film. The average distance a particle can travel before a collision is known as the mean free path, and a vacuum is essential to make this path long enough to cross the chamber.

The Threat of Contamination

Even if some material reached the substrate, it would be catastrophically contaminated. Reactive gases like oxygen and water vapor are particularly problematic.

They readily react with the hot, fresh surface of the growing film and the substrate itself, forming unwanted oxides and other compounds. This contamination completely alters the intended electrical, optical, and mechanical properties of the film, rendering it useless for high-performance applications like semiconductors or medical implants.

The Solution: Creating a Controlled Environment

A vacuum system is not just about removing air; it's about taking absolute control of the deposition environment. By pumping out the atmospheric gases, we enable the physics required for high-quality film growth.

Increasing the Mean Free Path

By reducing the pressure inside the chamber, we dramatically decrease the number of "obstacle" molecules. This increases the mean free path of the deposition atoms from nanometers to many meters—far longer than the distance from the source to the substrate.

This ensures a line-of-sight trajectory, allowing the material to coat the substrate evenly and predictably. This is the foundation of creating films with uniform thickness.

Ensuring Film Purity

Pumping out the chamber removes the reactive contaminants like oxygen and water. This creates a pristine environment where the film being grown is composed only of the intended source material.

This purity is critical. For a microprocessor, even a few stray atoms of oxygen can ruin a transistor's performance. For a medical implant, a pure, biocompatible coating is essential for safety.

Enabling Plasma and Gas Control

For many advanced deposition methods like sputtering and Chemical Vapor Deposition (CVD), a vacuum is a prerequisite. Sputtering requires a low-pressure environment to ignite and sustain a plasma, which is used to bombard the source material.

In CVD, a vacuum is first created to purge the chamber of contaminants. Then, specific precursor gases are introduced at very precise, low pressures. The vacuum allows for exact control over the partial pressure of each reactant gas, which dictates the chemical reaction and the final film composition.

Understanding the Trade-offs

While essential, implementing a vacuum system introduces its own set of practical and economic considerations. The level of vacuum required is directly tied to the sensitivity of the application.

Vacuum Level vs. Application

Not all processes require an ultra-high vacuum (UHV).

- Low Vacuum: Often sufficient for simpler processes like decorative coatings on plastic, where some imperfection is tolerable.

- High Vacuum (HV): The standard for most industrial electronics, optical coatings, and metallization.

- Ultra-High Vacuum (UHV): Absolutely necessary for sensitive research, molecular beam epitaxy (MBE), and semiconductor manufacturing, where atomic-level contamination can cause device failure.

System Complexity and Cost

Achieving and maintaining a vacuum adds significant cost and complexity. The systems involve expensive components like turbo-molecular pumps, ion pumps, cryopumps, vacuum chambers, and precise gauges. The higher the required vacuum, the more complex and costly the system becomes.

Process Time and Throughput

Pumping a chamber down to a low pressure takes time. This "pump-down time" can be a significant part of the total process cycle, directly impacting manufacturing throughput. There is a constant engineering trade-off between the quality achieved by a better vacuum and the speed demanded by production.

Making the Right Choice for Your Goal

The decision on vacuum level is always a function of the desired outcome. You must balance the need for purity and control against the constraints of cost and time.

- If your primary focus is ultimate purity and atomic precision (e.g., semiconductor research): You must invest in an ultra-high vacuum (UHV) system to minimize all sources of contamination.

- If your primary focus is high-throughput industrial coating (e.g., hard coatings on tools): A robust high-vacuum (HV) system that balances pump-down time with sufficient purity is the most practical choice.

- If your primary focus is depositing complex compounds via CVD: Your system must prioritize precise gas-flow and pressure control within a high-vacuum environment.

Ultimately, controlling the deposition environment through a vacuum is the single most important factor in determining the final quality and performance of your thin film.

Summary Table:

| Challenge in Air | Solution with Vacuum | Benefit |

|---|---|---|

| Atmospheric collisions scatter particles | Increases mean free path for direct line-of-sight travel | Uniform, smooth film deposition |

| Contamination from oxygen, water vapor | Removes reactive gases for a pristine environment | Pure films with intended electrical/optical properties |

| Uncontrolled gas reactions | Enables precise plasma/gas control (e.g., in sputtering/CVD) | Tailored film composition and high-performance results |

Ready to achieve flawless thin films? KINTEK specializes in high-performance vacuum systems and lab equipment tailored for deposition processes like sputtering, CVD, and evaporation. Whether you're in semiconductor manufacturing, optical coatings, or medical device development, our solutions ensure the purity, precision, and control your research or production demands. Contact us today to discuss how we can optimize your thin film deposition process!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition