Introduction

Table of Contents

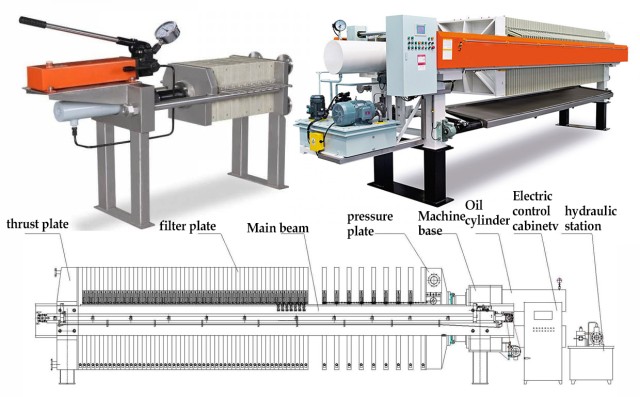

Laboratory filter presses and industrial-scale filter presses are both essential tools used in various industries. While laboratory filter presses are designed for smaller-scale applications, industrial-scale filter presses are built to handle larger volumes. In this blog post, we will compare and analyze the features, advantages, disadvantages, and costs of these two types of filter presses. Understanding the differences between laboratory and industrial-scale filter presses will help businesses make informed decisions about which option best suits their specific needs. Let's dive into the world of filter presses and explore their capabilities!

Definition and Features of Laboratory Filter Presses

Size and Volume Capacity

Laboratory filter presses are a type of filter press that are specifically designed for laboratory applications. They are used to separate solids from liquids in small batch processes and are typically used in research and development laboratories, quality control laboratories, and small-scale production facilities.

1.filter cloth2.filter plate(Solid Steel)3.Diaphragm plate(Hollow Plastic)4.filter chamber5.Compressed Air--Air Compressor6.One Pressure Slurry←-Feeding Pump7.Filtrate→Filtrate tank→Hot water station8.blowback9.filtrate10.One truck of filter cake (dry red mud) is transported to the red mud warehouse

Features:

- Small size: Laboratory filter presses are typically smaller than industrial-scale filter presses, making them ideal for benchtop use.

- Low volume capacity: Laboratory filter presses are designed for low volume applications, typically with a capacity of a few liters to a few dozen liters.

- Manual operation: Some laboratory filter presses are manually operated, allowing for precise control of the filtration process.

- Stainless steel construction: Laboratory filter presses are typically constructed of stainless steel, making them durable and corrosion resistant.

Operational Mode

Laboratory filter presses offer a high degree of control over the filtration process. They provide a high degree of control, allowing for precise adjustments to be made to optimize filtration efficiency. They are easy to operate and offer flexibility in terms of adjusting parameters such as pressure, temperature, and filtration time.

Material of Construction

Laboratory filter presses are typically constructed of stainless steel, which makes them durable and corrosion resistant. Stainless steel construction ensures that the filter press can withstand the rigors of laboratory use and can be easily cleane

d and maintained.

In summary, laboratory filter presses are a useful tool for small-scale filtration applications in research and development, quality control, and small-scale production. They offer a high degree of control over the filtration process, are cost-effective, and are easy to clean and maintain. However, they have a limited capacity, may require manual operation, and have limited pressure options compared to industrial-scale filter presses.

Laboratory filter presses and industrial-scale filter presses can vary significantly in cost, depending on their size, capacity, and features. Generally speaking, laboratory filter presses are smaller and less expensive than industrial-scale filter presses, but this can also depend on the specific model and manufacturer.

Applications of Laboratory Filter Presses

Research and Development

Laboratory filter presses are commonly used in research and development labs to test the filtration properties of new materials or to optimize filtration processes. These filter presses offer a high degree of control over the filtration process, allowing for precise adjustments to be made to optimize filtration efficiency. They are also typically smaller in size, making them ideal for benchtop use in the lab. Laboratory filter presses are designed for low volume applications, typically with a capacity of a few liters to a few dozen liters. Some laboratory filter presses are manually operated, allowing for precise control of the filtration process. They are also constructed of stainless steel, making them durable and corrosion resistant.

Quality Control

Laboratory filter presses are used in quality control labs to ensure that products meet certain filtration standards and to identify any potential issues with the filtration process. These filter presses offer a high degree of control over the filtration process, allowing for precise adjustments to be made to optimize filtration efficiency. They are typically smaller in size, making them ideal for benchtop use in the lab. Laboratory filter presses are designed for low volume applications, typically with a capacity of a few liters to a few dozen liters. Some laboratory filter presses are manually operated, allowing for precise control of the filtration process. They are also constructed of stainless steel, making them durable and corrosion resistant.

Small-scale Production

Laboratory filter presses can be used for small-scale production of products that require solid-liquid separation, such as pharmaceuticals or food products. These filter presses offer a high degree of control over the filtration process, allowing for precise adjustments to be made to optimize filtration efficiency. They are typically smaller in size, making them ideal for benchtop use in the lab. Laboratory filter presses are designed for low volume applications, typically with a capacity of a few liters to a few dozen liters. Some laboratory filter presses are manually operated, allowing for precise control of the filtration process. They are also constructed of stainless steel, making them durable and corrosion resistant.

In summary, laboratory filter presses are a useful tool for small-scale filtration applications in research and development, quality control, and small-scale production. They offer a high degree of control over the filtration process, are cost-effective, and are easy to clean and maintain. However, they have a limited capacity, may require manual operation, and have limited pressure options compared to industrial-scale filter presses.

Filter Press Applications

Filter presses can be built in a wide range of sizes, from small, lab-scale 150 mm presses, to those with much larger capacities, such as those with 1500 and 2000 mm filter plates. Filter presses are used for liquid/solid separation in an extensive range of industries and applications including:

- Food and beverage processing

- Chemical manufacturing

- Mining

- Power generation

- Aggregates, asphalt and cement production

- Steel mills

- Municipal plants

![Filter press application]()

Filter press application

Customizing A Filter Press for Your Application Needs

If you are considering using a filter press for your specific application, it is important to customize the filter press to meet your needs. Here are some factors to consider when customizing a filter press:

- Size: Choose a filter press size that matches your volume requirements. Laboratory filter presses are typically smaller in size and have a lower capacity compared to industrial-scale filter presses.

- Material of Construction: Consider the material of construction for your filter press. Laboratory filter presses are often constructed of stainless steel, which is durable and corrosion resistant.

- Automation: Decide whether you want a manual or automated filter press. Laboratory filter presses can be manually operated, allowing for precise control of the filtration process.

- Pressure Options: Consider the pressure options available for the filter press. Laboratory filter presses may have limited pressure options compared to industrial-scale filter presses.

In conclusion, laboratory filter presses are valuable tools for small-scale filtration applications in research and development, quality control, and small-scale production. They offer a high degree of control over the filtration process and are suitable for low volume applications. However, they may have limitations in terms of capacity and pressure options compared to industrial-scale filter presses.

Advantages of Laboratory Filter Presses

Versatility

Laboratory filter presses offer versatility in terms of filter media. They can be used with various filter media such as filter papers, filter cloths, and membrane filters. This flexibility allows researchers and professionals to choose the most suitable filter media for their specific application.

Cost-effectiveness

Laboratory filter presses are generally less expensive than industrial-scale filter presses. This makes them a cost-effective option for small-scale applications, especially for research and development labs, quality control labs, and small-scale production.

Ease of Maintenance

Laboratory filter presses are designed to be easy to clean and maintain. They typically have simple designs that are easy to disassemble and reassemble. This makes routine maintenance tasks, such as cleaning the filter plates or replacing the filter media, quick and efficient.

High Degree of Control

One of the key advantages of laboratory filter presses is the high degree of control they offer over the filtration process. Researchers and professionals can make precise adjustments to optimize filtration efficiency, ensuring reliable and accurate results.

Small Volume Requirements

Laboratory filter presses are ideal for filtering small volumes of liquid. They can efficiently filter small amounts of material, making them suitable for applications where only limited quantities of samples are available.

In summary, laboratory filter presses provide several advantages for small-scale filtration applications. They offer versatility in terms of filter media, are cost-effective, and are easy to clean and maintain. Additionally, they provide a high degree of control over the filtration process and can handle small volume requirements. However, it's important to note that they have a limited capacity compared to industrial-scale filter presses and may require manual operation.

Disadvantages of Laboratory Filter Presses

Laboratory filter presses are a useful tool for small-scale filtration applications in research and development, quality control, and small-scale production. They offer a high degree of control over the filtration process, are cost-effective, and are easy to clean and maintain. However, they do have some disadvantages that should be considered.

1. Limited Capacity

One of the main disadvantages of laboratory filter presses is their limited capacity. These presses are designed for low volume applications and may not be suitable for larger-scale filtration needs. Their capacity typically ranges from a few liters to a few dozen liters, which may not be sufficient for certain applications.

2. Manual Operation

Some laboratory filter presses require manual operation, which can be time-consuming and less efficient compared to automated systems. Manual operation involves tasks such as adjusting pressure, releasing the cake, and cleaning the press. This manual involvement can slow down the filtration process and require more labor.

3. Limited Pressure Options

Laboratory filter presses may have limited pressure options compared to industrial-scale filter presses. The pressure applied during the filtration process is an important factor in achieving efficient separation. Limited pressure options can restrict the range of applications for laboratory filter presses and may not be suitable for certain filtration requirements.

Overall, laboratory filter presses have their advantages in terms of control, cost-effectiveness, and ease of maintenance. However, their limited capacity, manual operation, and limited pressure options should be considered when deciding on the appropriate filtration equipment for your specific needs.

Source: Reference to the provided content.

Cost Comparison of Laboratory Filter Presses and Industrial-Scale Filter Presses

Size, Capacity, and Features Dependent Cost Variance

Laboratory filter presses and industrial-scale filter presses can vary significantly in cost, depending on their size, capacity, and features. Generally speaking, laboratory filter presses are smaller and less expensive than industrial-scale filter presses, but this can also depend on the specific model and manufacturer.

In general, the cost of a laboratory filter press can range from a few thousand dollars to tens of thousands of dollars, depending on the size, capacity, and features. The cost of an industrial-scale filter press can range from tens of thousands of dollars to hundreds of thousands of dollars, depending on the size, capacity, and features.

Cost-effectiveness of Laboratory Filter Presses for Small-Scale Applications

Laboratory filter presses are a useful tool for small-scale filtration applications in research and development, quality control, and small-scale production. They offer a high degree of control over the filtration process, are cost-effective, and are easy to clean and maintain. However, they have a limited capacity, may require manual operation, and have limited pressure options compared to industrial-scale filter presses.

Higher Cost of Industrial-Scale Filter Presses Due to Advanced Features

Industrial-scale filter presses, on the other hand, are designed for larger-scale filtration applications and are typically more automated and have a greater capacity than laboratory filter presses. They may also have more advanced features, such as programmable controls, automatic cake release, and membrane squeeze options. However, they are also generally more expensive than laboratory filter presses due to their larger size, greater capacity, and more advanced features.

Ultimately, the choice between a laboratory filter press and an industrial-scale filter press will depend on the specific requirements of the filtration application, including the size and capacity needed, the level of automation and features required, and the budget available.

Conclusion

In conclusion, laboratory filter presses offer several advantages for small-scale applications in research, development, quality control, and small-scale production. They provide a high degree of control, allowing researchers to fine-tune the filtration process. With their small volume requirements, they are cost-effective and versatile, accommodating various materials. Although they have limited capacity and require manual operation, these drawbacks are outweighed by their affordability and ease of maintenance. However, for larger-scale industrial applications, industrial-scale filter presses with advanced features may be necessary, despite their higher cost. Ultimately, the choice between laboratory and industrial-scale filter presses depends on the specific needs and scale of the filtration process.

If you are interested in our products, please visit our company website:https://kindle-tech.com/product-categories/heated-lab-press, where innovation has always been a priority. Our R&D team consists of experienced engineers and scientists who closely follow industry trends and are constantly pushing the boundaries of what is possible. Our laboratory equipment incorporates the latest technology to ensure that you can obtain accurate and repeatable results during your experiments. From high-precision instruments to intelligent control systems, our products will provide you with unlimited possibilities for your experimental work.

Related Products

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

Related Articles

- What is lab hydraulic press

- An Insight into Hydraulic Presses: Versatility, Efficiency, and Industrial Applications

- Applications and Importance of Hydraulic Press in Laboratories

- Understanding Filter Press: Function, Components, and Applications

- Lab Scale Mini Tablet Press: Applications, Processes, and Features