Understanding Sample and Test Method

Sample Purity and Composition

The purity of the sample is a critical factor in ensuring accurate infrared spectroscopy analysis. Ideally, the sample should exhibit a purity level exceeding 98% to minimize interference from impurities. Additionally, the presence of free water should be strictly avoided, as it can significantly distort the spectral results.

When preparing a sample for infrared spectroscopy, it is essential to document comprehensive details about the sample's characteristics. This includes noting the source of the sample, which can provide insights into potential contaminants or variations. The sample's physical properties such as color, smell, boiling point, melting point, refractive index, and state (solid, liquid, or gas) should also be meticulously recorded. These attributes can influence the sample's behavior during analysis and provide context for interpreting the spectral data.

| Property | Importance |

|---|---|

| Purity | Ensures minimal interference from impurities; should be above 98% |

| Free Water | Avoids spectral distortion; should be absent |

| Source | Provides context and potential contamination insights |

| Color | Can indicate the presence of certain compounds |

| Smell | May suggest the presence of volatile compounds |

| Boiling Point | Influences handling and preparation methods |

| Melting Point | Important for solid samples; affects preparation |

| Refractive Index | Provides additional data on sample composition |

| State | Determines the appropriate preparation and analysis techniques |

By carefully documenting these details, analysts can better understand the sample's composition and anticipate any potential challenges during the infrared spectroscopy process. This meticulous approach ensures that the spectral data obtained is reliable and interpretable, leading to more accurate and meaningful results.

Elemental Analysis and Molecular Formula

Elemental analysis is a crucial step in determining the molecular formula of a compound. This analysis provides essential data, such as the relative molecular mass or the molecular ion peak, which are often obtained through mass spectrometry. These results are pivotal in identifying the exact composition of the molecule.

For instance, the relative molecular mass, derived from elemental analysis, offers a direct measure of the molecule's total mass relative to the mass of a reference atom, typically carbon-12. This information, combined with the molecular ion peak, which indicates the mass of the molecule minus one electron, can be used to deduce the molecular formula.

Moreover, elemental analysis can also reveal the presence of isotopes, which are atoms of the same element with different atomic masses. This additional detail can further refine the molecular formula, ensuring a more accurate representation of the compound's structure.

In summary, elemental analysis, through techniques like mass spectrometry, plays a vital role in determining the molecular formula by providing key data on the molecule's mass and composition.

Gas Sample Preparation

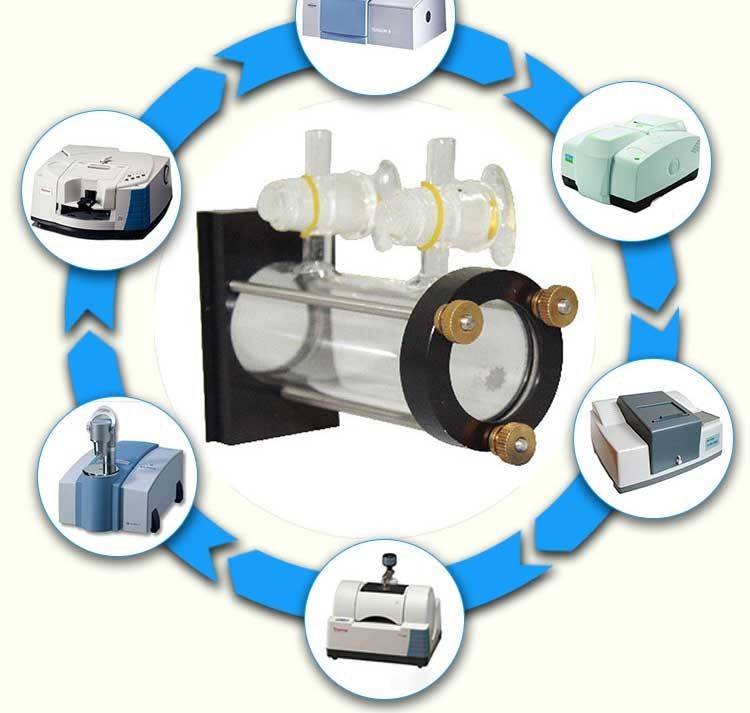

Gas Absorption Cell

Gas samples are meticulously analyzed using a gas absorption cell, a critical component in infrared spectroscopy. The process begins with the cell being thoroughly evacuated to eliminate any residual gases, thereby ensuring a pristine environment for the sample. This vacuum state creates a negative pressure, which serves as the driving force to draw the gas sample into the cell. The precise control of this negative pressure is crucial, as it directly influences the accuracy and reproducibility of the spectroscopic measurements.

Once the gas sample is introduced into the cell, it is evenly distributed to ensure that the entire volume of the cell is utilized for absorption measurements. This even distribution is essential for obtaining a comprehensive spectrum that accurately reflects the sample's molecular composition and structure. The cell's design, which includes multiple internal reflections to enhance sensitivity, further contributes to the precision of the analysis, especially for low concentration samples.

In summary, the gas absorption cell plays a pivotal role in the infrared spectroscopy of gas samples, ensuring that the sample is accurately and reliably analyzed through meticulous control of pressure and distribution.

Concentration and Pressure Considerations

For low concentration samples, a multiple reflection gas cell is highly recommended due to its ability to enhance the signal-to-noise ratio by increasing the effective path length. This type of cell is particularly advantageous for detecting trace components in a gas mixture.

When conducting quantitative analysis, it is crucial to ensure that the total pressure within the gas pool is equalized. This balance is essential for maintaining accurate and reproducible measurements. Pressure fluctuations can lead to variations in the absorption spectra, which can skew the quantitative results.

To achieve optimal pressure equilibrium, several strategies can be employed:

- Pressure Regulation Systems: Utilizing automated pressure regulation systems can help maintain a consistent pressure within the gas cell.

- Temperature Control: Ensuring that the gas cell is maintained at a stable temperature can also aid in pressure stabilization.

- Regular Calibration: Periodic calibration of the pressure sensors and regulation equipment is necessary to ensure their accuracy and reliability.

By implementing these measures, the precision and accuracy of infrared spectroscopy analysis for low concentration gas samples can be significantly improved.

Liquid Sample Preparation

Sample Injection and Liquid Layer Thickness

When dealing with samples characterized by low boiling points and high volatility, careful consideration must be given to the injection process and the thickness of the liquid layer. These samples are typically introduced into a closed liquid pool, a method that ensures stability and minimizes the risk of sample loss due to evaporation.

The optimal liquid layer thickness for such volatile samples ranges from 0.01 to 1 millimeter. This narrow range is crucial as it balances the need for sufficient sample concentration with the requirement to prevent excessive evaporation. A thinner layer might not provide enough material for accurate analysis, while a thicker layer could lead to rapid evaporation, compromising the integrity of the sample.

To achieve this precise liquid layer thickness, specialized equipment and techniques are employed. The injection process is meticulously controlled to ensure that the sample is evenly distributed across the pool, creating a uniform layer that facilitates accurate spectroscopic measurements. This approach not only enhances the precision of the analysis but also extends the operational window for volatile samples, making it possible to study materials that would otherwise be difficult to handle.

In summary, the controlled injection of highly volatile samples into a closed liquid pool with a carefully managed layer thickness is essential for successful infrared spectroscopy analysis. This method ensures that the sample remains stable and adequately concentrated, enabling reliable and reproducible results.

Solvent Selection and Solution Preparation

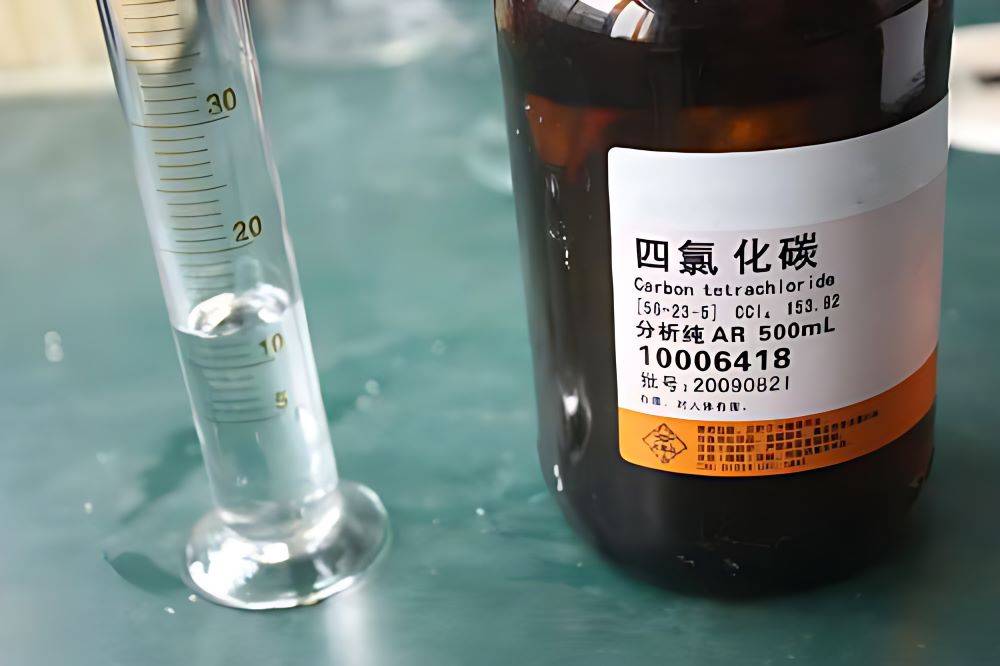

When preparing liquid samples for infrared spectroscopy, the choice of solvent is crucial. Commonly used solvents include carbon tetrachloride, carbon disulfide, dichloromethane, and acetone. These solvents are selected based on their ability to dissolve the sample without interfering with the infrared spectrum.

The concentration of the solution is typically maintained between 3% and 5%. This range ensures that the sample is adequately dissolved while minimizing the risk of solvent interference. The concentration can be adjusted depending on the solubility of the sample and the specific requirements of the analysis.

For instance, carbon tetrachloride is often preferred for its low absorbance in the infrared region, making it suitable for analyzing samples with strong absorption bands. On the other hand, acetone is commonly used for its high solubility in water, making it ideal for aqueous samples.

In summary, selecting the right solvent and preparing the solution at the appropriate concentration are critical steps in ensuring accurate and reliable infrared spectroscopy results.

Solid Sample Preparation

Common Preparation Methods

When preparing solid samples for infrared spectroscopy, several methods are employed to ensure accurate and reliable data. The most common techniques include potassium bromide (KBr) tableting, halide crystal coating, thin film method, and powder method. Each method has its unique advantages and is suited for different types of samples and analytical requirements.

-

Potassium Bromide Tableting: This method is widely used due to its simplicity and effectiveness. The sample is mixed with potassium bromide, which is then pressed into a transparent disk. This technique is particularly useful for solid samples that can be ground into a fine powder. The resulting disk is transparent to infrared light, allowing for clear spectral data acquisition.

-

Halide Crystal Coating: This method involves coating the sample onto a halide crystal, such as sodium chloride (NaCl) or potassium bromide (KBr). It is particularly useful for samples that are sensitive to grinding or those that need to be analyzed in their native form. The coating process is delicate and requires precise control to ensure uniform coverage.

-

Thin Film Method: The thin film method is ideal for samples that can be melted or dissolved in a volatile solvent. The sample is then cast onto a substrate and allowed to dry, forming a thin film. This method is advantageous for samples that need to be analyzed in a specific phase, such as liquid or solid.

-

Powder Method: This technique involves dispersing the sample in a non-absorbing medium, such as mineral oil or paraffin. The mixture is then placed between two plates and subjected to infrared analysis. The powder method is particularly useful for samples that are difficult to grind or those that require a high degree of homogeneity.

Among these methods, potassium bromide tableting stands out as the most prevalent due to its ease of use and the high-quality spectra it produces. However, the choice of method depends on the specific characteristics of the sample and the analytical goals.

Tableting Process and Issues

The preparation of solid samples for infrared spectroscopy often involves a critical step known as tableting. This process requires the test sample to be thoroughly dried and finely ground to ensure optimal results. The primary objective is to create a homogeneous mixture that can be compressed into a stable tablet without compromising the sample's integrity.

During the tableting process, several common issues may arise. One of the most frequent problems is the appearance of opacity in the tablet, which can hinder the transmission of infrared light and affect the accuracy of the analysis. This opacity is often due to the incomplete grinding of the sample, leading to uneven particle distribution within the tablet. To mitigate this issue, it is crucial to ensure that the sample is ground to a particle size that allows for uniform compression.

Another common challenge is the occurrence of cloudiness in the tablet. This phenomenon is typically caused by the presence of moisture or volatile components in the sample, which can lead to the formation of bubbles or voids during the tableting process. To address this, samples should be carefully dried under controlled conditions to remove any residual moisture before grinding and tableting.

Light scattering is yet another issue that can arise during the tableting process. This can be attributed to the presence of large particles or aggregates within the sample, which scatter the incident infrared light and reduce the signal-to-noise ratio. To minimize light scattering, it is essential to employ a grinding method that ensures the sample particles are uniformly sized and free from aggregates.

In summary, the tableting process for solid samples in infrared spectroscopy requires meticulous attention to detail to avoid common issues such as opacity, cloudiness, and light scattering. By ensuring the sample is properly dried and ground, and by employing appropriate tableting techniques, these challenges can be effectively managed, leading to more accurate and reliable spectroscopic analysis.

Related Products

- No Demolding Lab Infrared Press Mold for Laboratory Applications

- Lab Infrared Press Mold

- Infrared Heating Quantitative Flat Plate Press Mold

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- kbr pellet press 2t

Related Articles

- Simplify Sample Preparation with FTIR Pellet Press

- Understanding Cold Isostatic Pressing and its Types

- FTIR Pellet Press The Ultimate Solution for Precise Sample Preparation

- The Benchtop KBr Pellet Press: An Efficient Tool for Laboratory Use

- Infrared Press Mold Techniques for Non-Demolding Applications