The laboratory is a place of variables. We obsess over the purity of our reagents and the precision of our scales. Yet, often, we treat heat as a blunt instrument. We set a dial to 1000°C and assume the environment inside the chamber is absolute.

It rarely is.

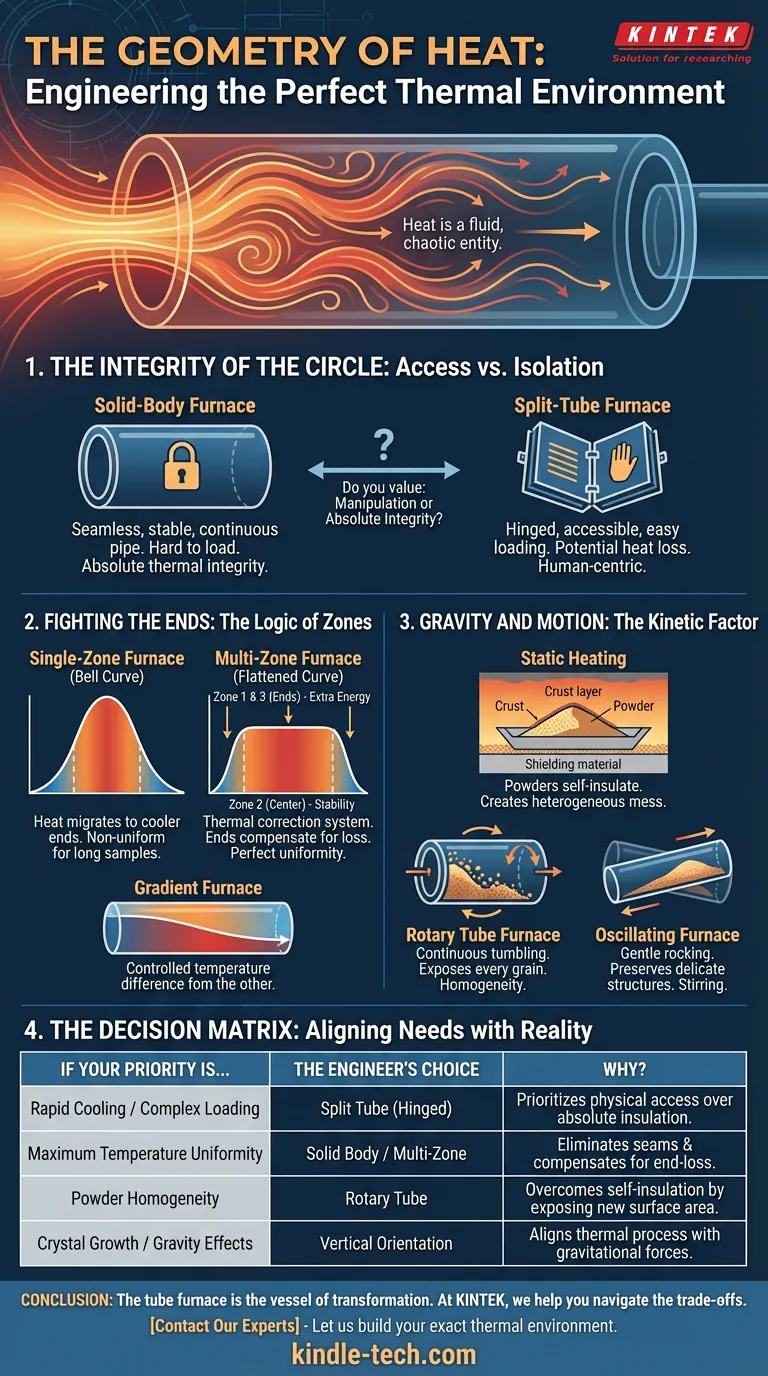

Heat is a fluid, chaotic entity. It seeks to escape. It clusters in corners. It drifts.

Choosing a tube furnace is not merely about purchasing a piece of hardware; it is about choosing a strategy to contain and manipulate this chaos. It is an engineering decision about how your sample interacts with the universe of thermodynamics.

At KINTEK, we believe that understanding the "personality" of your furnace—its geometry, its zoning, and its movement—is just as critical as the chemistry occurring inside it.

The Integrity of the Circle: Access vs. Isolation

The first decision in thermal engineering is physical. It is a battle between human convenience and thermal perfection.

The Solid-Body Furnace Imagine a continuous pipe. A solid, non-split furnace is a seamless cylinder of insulation and heating elements. Because there are no breaks in the architecture, the thermal profile is incredibly stable. Heat has no easy escape route.

However, the physicist’s dream is the operator’s headache. You must thread your sample through the end. If you have complex flanges or fragile setups, this is risky.

The Split-Tube Furnace Here, we introduce a hinge. The furnace opens like a clam.

This is the "human-centric" design. You can lay your reactor tube directly into the heating elements. You can cool the sample rapidly by opening the chassis. But every seam is a potential leak for energy.

The trade-off is clear: Do you value the ease of manipulation (Split) or the absolute integrity of the thermal envelope (Solid)?

Fighting the Ends: The Logic of Zones

If you heat a tube in the center, physics dictates that heat will migrate toward the cooler ends. In a Single-Zone furnace, this creates a bell curve. The center is hot; the edges are cooling down.

For small samples, this is acceptable. For long samples requiring uniformity, it is a disaster.

The Multi-Zone Solution To fight this natural gradient, we use Multi-Zone furnaces. A standard three-zone furnace acts as a thermal correction system.

- Zone 1 & 3 (Ends): These work harder, pumping in extra energy to compensate for the heat loss at the tube's openings.

- Zone 2 (Center): This maintains stability.

The result is a flattened curve—a long, extended area of perfect uniformity.

Conversely, some researchers need the chaos. Gradient Furnaces intentionally drive a temperature difference from one end to the other, allowing materials to be tested across a spectrum of temperatures simultaneously. It is controlled instability.

Gravity and Motion: The Kinetic Factor

Most heating is static. The sample sits; the heat washes over it. But what if the sample hides from the heat?

Powders and granules are notorious insulators. If you heat a pile of powder in a static boat, the top layer creates a crust, shielding the material beneath. The result is a heterogeneous mess.

The Rotary Approach The solution is kinetic energy. Rotary Tube Furnaces turn the entire process tube. The powder tumbles. Every grain is exposed to the atmosphere and the heat source in a continuous cycle.

The Oscillating Alternative Sometimes, rotation is too aggressive. Oscillating furnaces gently rock the tube. It is the difference between a blender and a gentle stir. This preserves delicate structures while ensuring that heat—and gas flow—reaches every micron of the sample.

The Decision Matrix

There is no "perfect" furnace. There is only the furnace that aligns with the constraints of your experiment.

We often see researchers over-specifying (buying complexity they don’t need) or under-specifying (ignoring the physics of their sample).

Here is how to align your needs with the engineering reality:

| If your priority is... | The Engineer's Choice | Why? |

|---|---|---|

| Rapid Cooling / Complex Loading | Split Tube (Hinged) | Prioritizes physical access over absolute insulation. |

| Maximum Temperature Uniformity | Solid Body / Multi-Zone | Eliminates seams and compensates for end-loss. |

| Powder Homogeneity | Rotary Tube | Overcomes self-insulation by constantly exposing new surface area. |

| Crystal Growth / Gravity Effects | Vertical Orientation | Aligns the thermal process with gravitational forces. |

Conclusion

The tube furnace is the vessel of transformation. Whether you are growing crystals, sintering ceramics, or analyzing pyrolysis, the geometry of your equipment dictates the quality of your data.

You do not need to fight these variables alone.

At KINTEK, we specialize in the intersection of lab requirements and thermal engineering. We help you navigate the trade-offs between access and uniformity, static and dynamic processing.

Contact Our Experts today to discuss your specific application. Let us help you build the exact thermal environment your research demands.

Visual Guide

Related Products

- Multi-zone Laboratory Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

Related Articles

- Comprehensive Guide to Tube Furnaces: Types, Applications, and Considerations

- A Comprehensive Guide to Split Tube Furnaces: Applications, Features

- Advanced Laboratory Furnaces: Box, Muffle, and Tube Options for High-Temperature Applications

- Introducing the Lab Vacuum Tube Furnaces

- Exploring the Key Characteristics of Tube Heating Furnaces