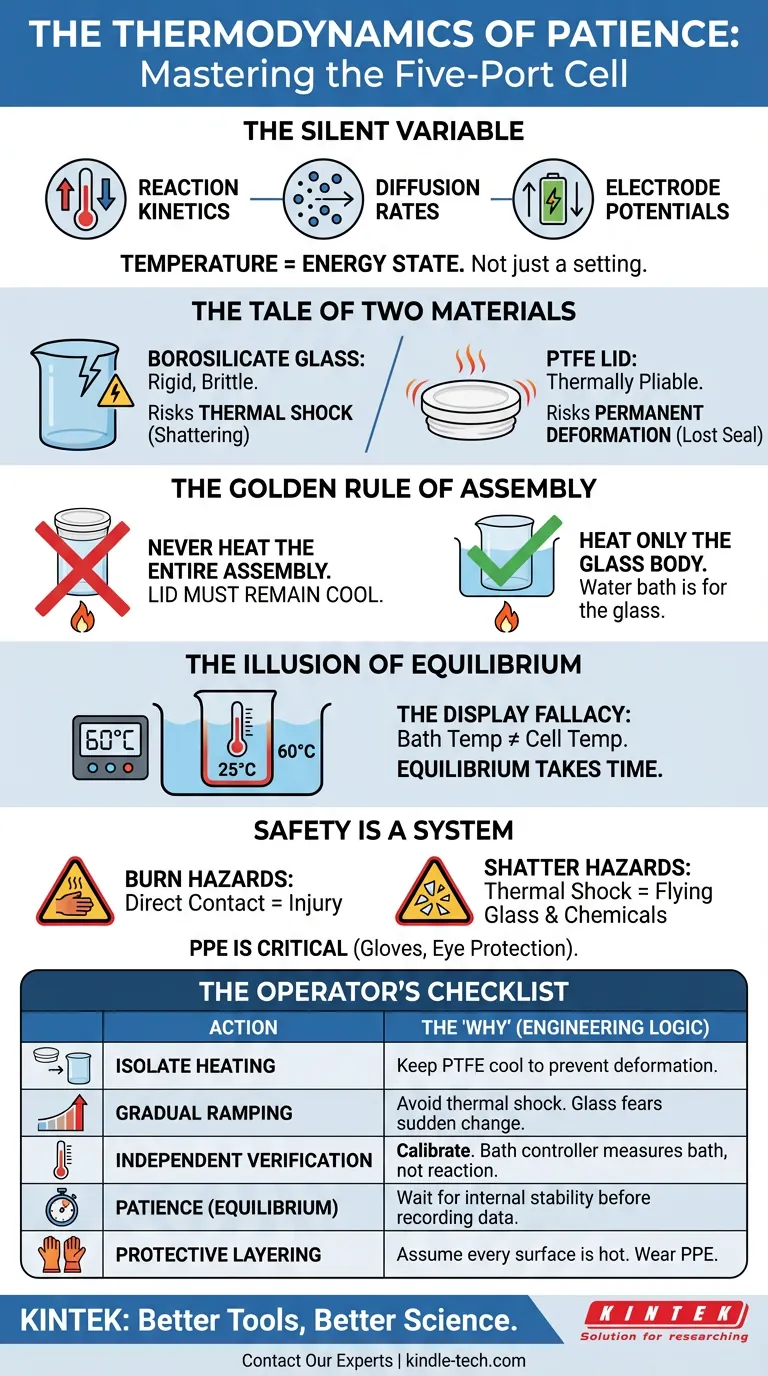

The Silent Variable

In electrochemistry, temperature is not merely a setting on a dial. It is an energy state.

It dictates reaction kinetics. It governs diffusion rates. It shifts electrode potentials.

Yet, in the rush to gather data, we often treat the five-port water bath electrolytic cell as a static vessel. We assume the temperature on the controller is the truth. We assume the materials will comply with our schedule.

This is a mistake.

The core challenge of high-precision chemistry is not just the reaction itself. It is managing the tension between the need for heat and the physical limitations of your hardware.

The Tale of Two Coefficients

An electrolytic cell is an engineering marriage between two very different materials: Borosilicate glass and Polytetrafluoroethylene (PTFE).

They live together happily at room temperature. But add heat, and the relationship strains.

The Glass Body: It is rigid and brittle. It respects structure but fears sudden change. Subject it to thermal shock—a rapid spike or drop in temperature—and it will shatter.

The PTFE Lid: It is chemical-resistant but thermally pliable. When heated, it expands. Unlike glass, it has a "memory" problem. If you heat the entire assembly (lid included), the PTFE deforms. When it cools, it does not return to its original shape.

The seal is lost. The component is ruined.

The Golden Rule of Assembly

There is one rule that cannot be broken:

Never heat the entire assembly.

The water bath circulation system is designed for the glass body. The lid must remain cool. This mismatch in thermal behavior is why only the glass body can be autoclaved. Sterilizing the full assembly is a sentence of death for the lid.

The Illusion of Equilibrium

There is a psychological trap in lab work called "The Display Fallacy."

You set the water bath to 60°C. The display reads 60°C. You immediately inject your electrolyte and begin the scan.

Your data will be wrong.

The bath is 60°C. The glass wall is transitioning. The electrolyte in the center is likely still 25°C.

Thermal equilibrium is a function of time, not just energy.

For reproducible results—the kind that stand up to peer review—you must wait. For high-precision work, do not trust the bath controller. Place a calibrated thermometer directly inside the cell.

Safety is a System

Beyond the data, there is the operator.

Thermal control systems are inherently hazardous. We get comfortable with them because water looks benign. But hot glass looks exactly like cold glass.

- Burn Hazards: Direct contact with the bath or the cell body causes immediate injury.

- Shatter Hazards: A thermal shock fracture can send glass shards and hot chemicals across the bench.

PPE (heat-resistant gloves and eye protection) is not a formality. It is the only barrier between your skin and a physics failure.

The Operator's Checklist

To navigate these risks, we must adopt a strict protocol.

Here is the operational framework for maintaining both safety and data integrity:

| Action | The "Why" (Engineering Logic) |

|---|---|

| Isolate Heating | Heat only the glass body. Keep the PTFE lid cool to prevent permanent deformation. |

| Gradual Ramping | Avoid thermal shock. Glass handles high heat, but not sudden heat. |

| Independent Verification | Calibrate. The bath controller measures the bath, not your reaction. |

| Patience (Equilibrium) | Wait for the internal temperature to stabilize before recording data. |

| Protective Layering | Assume every surface is hot. Wear heat-resistant gloves. |

Better Tools, Better Science

You cannot fight physics, but you can work with it.

Success in electrochemistry comes from understanding the limits of your materials and the variables of your environment. It requires patience, precision, and the right equipment.

At KINTEK, we design our lab equipment with these realities in mind. Our water baths and electrolytic cells are engineered to provide the stability you need, minimizing the variables that keep you up at night.

Do not let thermal fluctuation be the reason your experiment fails.

Visual Guide

Related Products

- Super Sealed Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell for Coating Evaluation

- Electrolytic Electrochemical Cell with Five-Port

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

Related Articles

- The Silent Dialogue: Mastering Control in Electrolytic Cells

- The Silence of the Seal: Why Electrochemical Precision is a Battle Against the Atmosphere

- The Anchor of Truth: Why Physical Stability Defines Electrochemical Success

- The Architecture of Precision: Mastering the Five-Port Water Bath Electrolytic Cell

- The Transparency Paradox: Mastering the Fragile Art of Electrolytic Cells