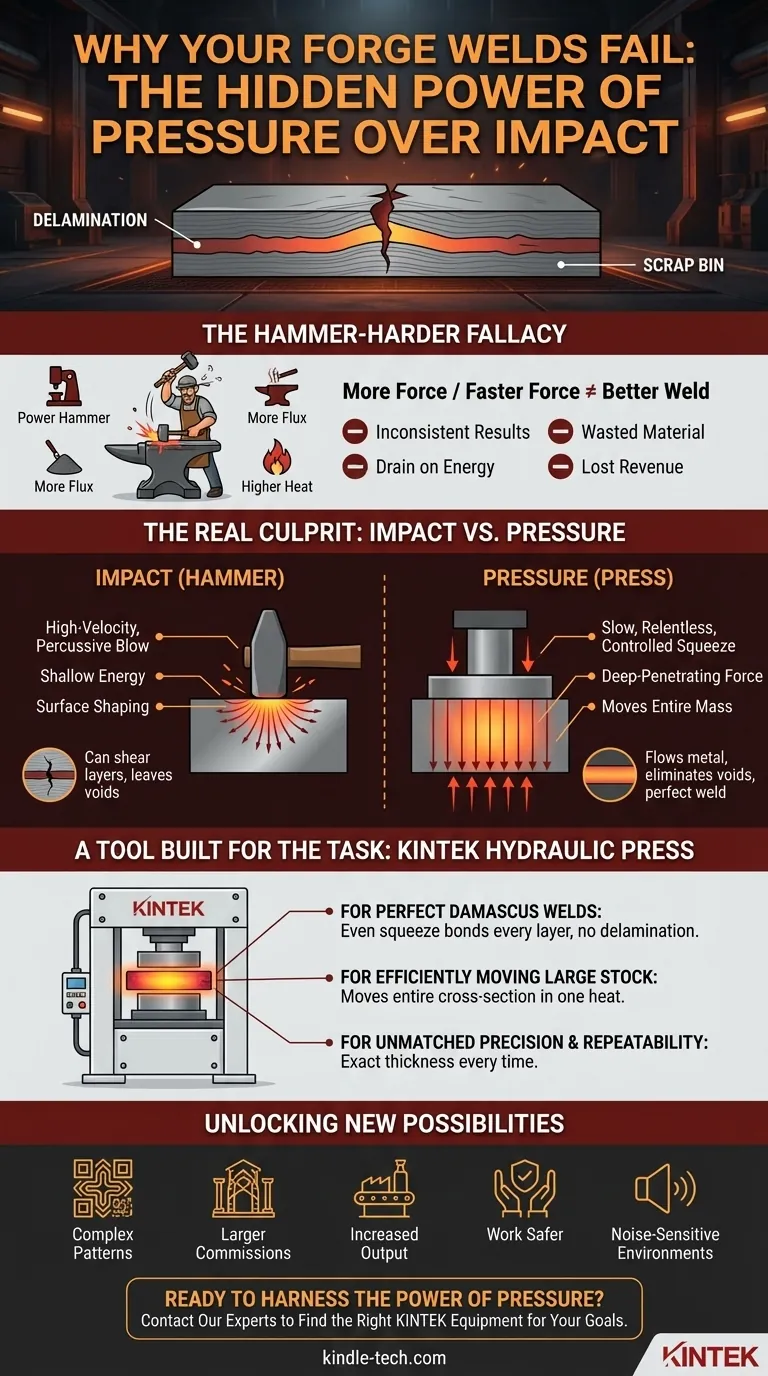

You’ve spent hours carefully stacking, welding, and folding the layers. The billet of high-carbon steel glows bright orange, a promise of the intricate pattern locked within. You bring it to the anvil for the final shaping, and then you hear it—not the clean ring of solid steel, but a dull, sickening thud. The layers have separated. The billet has delaminated. Hours of meticulous work and expensive material are now destined for the scrap bin.

If this scene feels painfully familiar, you are not alone. It’s one of the most frustrating moments in a smith's journey.

The Hammer-Harder Fallacy: Why More Force Isn't the Answer

When faced with stubborn welds or the monumental task of drawing out thick stock, our first instinct is often the same: we need more force. We swing the hand hammer harder. We invest in a powerful, high-speed power hammer. We think the problem is a lack of power.

So we try again. We use more flux, get the forge a little hotter, and hammer with more speed and aggression. Yet the results remain stubbornly inconsistent.

- Damascus billets still show small voids or fail entirely under stress.

- Drawing out a 2-inch bar feels like a battle of attrition, draining your energy and fuel for minimal progress.

- Achieving precise, repeatable thickness across a workpiece becomes a game of chance.

This isn't just a technical frustration; it's a business problem. Every failed billet is lost revenue. Every hour spent fighting a thick bar is an hour not spent on finishing work or starting a new project. Inconsistency erodes both your confidence and your customers' trust.

The frustrating truth is that more force, or even faster force, often isn’t the answer. The problem isn't the amount of force you're applying, but the kind of force.

The Real Culprit: Understanding Impact vs. Pressure

The core of the issue lies in a fundamental principle of physics that separates a hammer from a press. They deliver force in two completely different ways.

A Hammer Works by Impact

A hammer—whether it’s in your hand or a power hammer—delivers a high-velocity, percussive blow. Think of it like a stone skipping across the surface of a lake. The energy is intense but shallow, dissipating rapidly at the point of contact. This is perfect for shaping the surface of the metal, drawing a fine taper on a blade, or making quick, artistic adjustments.

However, for a deep forge weld in a thick billet, this surface-level impact can be a liability. It may not penetrate deeply enough to weld the innermost layers, or an off-center blow can even shear the layers apart.

A Press Works by Pressure

A hydraulic press operates on a completely different principle. It delivers a slow, relentless, and controlled squeeze. Imagine slowly pushing your entire hand into a block of soft clay. The force is distributed evenly, moving the entire mass from its core outwards.

This immense, deep-penetrating pressure is what’s needed for certain critical tasks. It gives the metal time to flow and form a perfect, void-free weld across every single layer of a damascus billet, simultaneously. It moves the entire cross-section of a thick bar with an efficiency a hammer can never match.

The "common solutions" fail because they are trying to solve a pressure problem with an impact tool. A bigger, faster hammer is just a bigger, faster skipping stone—it still won't move the whole body of water.

A Tool Built for the Task: How a Hydraulic Press Solves the Pressure Problem

To truly solve a problem of deep, uniform pressure, you need a tool that was specifically designed to deliver it. This is where a hydraulic press transitions from a workshop luxury to an essential piece of equipment.

It's not just another way to move metal; it's the right way for these specific, high-stakes jobs. A well-designed press, like those from KINTEK, is the physical embodiment of this principle.

- For Perfect Damascus Welds: The slow, even squeeze from a KINTEK hydraulic press ensures every layer in your billet reaches welding temperature and bonds perfectly, eliminating the delamination and voids caused by shallow hammer impacts.

- For Efficiently Moving Large Stock: Instead of spending hours hammering a thick bar, the press moves the entire cross-section of the metal in a single, controlled compression. What once took all morning can now be accomplished in a single heat.

- For Unmatched Precision and Repeatability: With precisely controlled ram movement and the use of stop blocks, you can press material to an exact thickness every single time, creating a level of consistency that is nearly impossible with a hammer.

Beyond Fixing Welds: Unlocking New Forging Possibilities

Once you stop fighting your material with the wrong kind of force, a whole new world of efficiency and creativity opens up. Solving the pressure problem isn't just about preventing failures; it's about enabling new successes.

With the controlled power of a hydraulic press, you can now confidently:

- Create more complex patterns in your damascus steel, knowing your welds are flawless.

- Take on larger, more profitable commissions involving thick stock for architectural work or large-scale tools.

- Increase your production output by dramatically reducing the time and physical effort required for initial forging steps.

- Work more safely with specialized dies for fullering, punching, or swaging without the risk of a misplaced hammer blow.

- Operate in a noise-sensitive environment, thanks to the near-silent operation compared to a deafening power hammer.

Ultimately, integrating the right tool for the job elevates your craft from a constant struggle to a predictable, efficient, and more creative process.

Solving these persistent forging challenges is about more than just better welds; it's about building a more successful and sustainable business. If you're ready to move beyond the limitations of impact and harness the power of controlled pressure, our team is here to help you find the right equipment for your specific goals. Let's discuss the projects you've been dreaming of tackling. Contact Our Experts.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery