Blog

Why Your High-Temperature Furnace Elements Fail: The Critical Difference in Silicon Carbide

2 months agoFurnace downtime from failing SiC heating elements costs time and money. Discover the critical material difference that ensures reliability in extreme applications.

Learn More

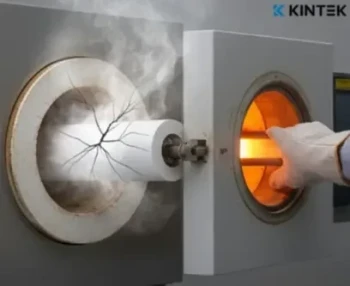

From Crack to Complete: A Scientist's Guide to Eliminating Catastrophic Tube Furnace Failures

2 months agoPrevent costly tube furnace bursts. Learn the key causes like thermal shock and material incompatibility, and discover the right strategy to ensure safety and data integrity.

Learn More

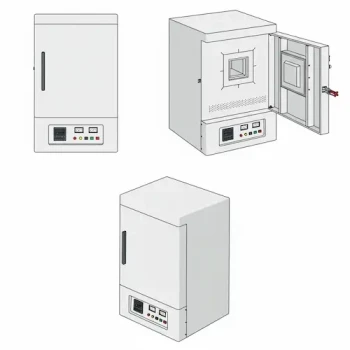

Beyond 1000°C: How Precision Furnaces Conquer the Hidden Enemy of Repeatable Results

2 months agoStruggling with inconsistent results from sintering or ashing? Discover how overcoming thermal instability with advanced muffle furnaces is key to reproducible research.

Learn More

Your Hydraulic Press Is Hot. Here’s Why It’s a Bigger Problem Than You Think.

2 months agoIs your lab's hydraulic press overheating? Learn why this is a critical sign of wasted energy and impending failure, and how to fix it permanently.

Learn More

AI completes muffle furnace scientific research graphing in one minute.

4 months agoHow to use nano banana to create scientific illustrations

Learn More

Risk-Proof Your Lab: How to Choose a Vacuum Pump That Avoids Costly Failures

5 months agoLearn how to choose reliable lab vacuum pumps to avoid costly failures. Assess chemical risks, throughput needs & safety for optimal performance.

Learn More

How to Select the Right Oil-Free Diaphragm Pump for Your Lab or Industrial Needs

5 months agoLearn how to choose the right oil-free diaphragm pump for your lab or industry—balancing specs, chemical resistance, and lifetime costs.

Learn More

How to Choose Laboratory Vacuum Pumps for Maximum Efficiency and Cost Savings

5 months agoLearn how to choose the right lab vacuum pump for efficiency & cost savings. Compare oil-sealed vs. oil-free pumps & future-proof your investment.

Learn More

How to Choose and Optimize Water Circulating Vacuum Pumps for Your Lab

6 months agoLearn how to choose and optimize water circulating vacuum pumps for lab applications, balancing efficiency and reliability.

Learn More

Water Circulating Vacuum Pumps: A Practical Guide for Laboratory Applications

6 months agoDiscover the benefits of water circulating vacuum pumps for labs: chemical safety, low maintenance, and explosion-proof operation. Ideal for sensitive applications.

Learn More

How to Choose Crucible Materials That Prevent Chemical Degradation in Vacuum Induction Melting

6 months agoLearn how to choose crucible materials for vacuum induction melting to prevent chemical degradation and optimize alloy purity. Essential guide for industrial applications.

Learn More

How Vacuum Induction Melting Prevents Catastrophic Material Failures in Critical Components

6 months agoDiscover how Vacuum Induction Melting (VIM) prevents material failures in aerospace, nuclear, and EV components by eliminating atomic-level contamination.

Learn More

How Vacuum Induction Melting Elevates High-Performance Alloy Production

6 months agoDiscover how Vacuum Induction Melting (VIM) enhances alloy purity, reduces defects, and optimizes costs for aerospace and energy sectors.

Learn More

How Vacuum Induction Melting Outperforms Traditional Methods in Advanced Alloy Production

6 months agoDiscover how vacuum induction melting (VIM) outperforms traditional methods in advanced alloy production, offering precision, purity, and cost savings.

Learn More

How Vacuum Induction Melting (VIM) Transforms High-Performance Alloy Production

6 months agoDiscover how Vacuum Induction Melting (VIM) enhances alloy purity for aerospace, medical, and nuclear industries, reducing defects and costs.

Learn More

How Vacuum Induction Melting Ensures Unmatched Reliability in Critical Industries

6 months agoVacuum induction melting (VIM) ensures metallurgical purity, durability, and efficiency in aerospace, nuclear, and critical industries. Learn why VIM outperforms traditional methods.

Learn More

How Vacuum Induction Melting Powers Superior Material Performance in Critical Industries

6 months agoDiscover how Vacuum Induction Melting (VIM) ensures 99.99% pure alloys for aerospace and medical industries, boosting performance and compliance.

Learn More

How Freeze-Drying Cuts Transport Costs by 90% in Critical Logistics

7 months agoFreeze-drying slashes transport costs by 90% in logistics for space, military, and disaster relief by reducing weight and volume. Learn how it works.

Learn More

Freeze-Drying Decoded: The Science Behind Preserving Food, Medicine, and Research Materials

7 months agoDiscover how freeze-drying preserves food, medicine, and research materials with unmatched efficiency. Learn the science behind lyophilization and its applications.

Learn More

Why Freeze-Drying is Indispensable for Preserving Sensitive Samples

7 months agoFreeze-drying preserves sensitive samples by sublimation, maintaining molecular integrity and enabling stable, room-temperature storage. Essential for proteins, vaccines, and volatile compounds.

Learn More

How Freeze-Drying Protects Delicate Biological Structures During Water Removal

7 months agoFreeze-drying preserves biological samples by removing water without structural damage, ideal for vaccines, enzymes, and microbial cultures. Learn how it works.

Learn More

How Laboratory Freeze Dryers Outperform Alternatives in Pharma, Food, Biotech & Research

7 months agoDiscover how lab freeze dryers outperform traditional methods in pharma, food, biotech & research—preserving potency, nutrients & integrity.

Learn More

How Cascade Refrigeration Powers Ultra-Low Temperature Freezers Beyond Single-Stage Limits

7 months agoLearn how cascade refrigeration enables ultra-low temperature freezers to reach -80°C and beyond, overcoming single-stage system limitations for critical sample storage.

Learn More

Why Ultra-Low Temps are Non-Negotiable: The Science Behind Preserving Critical Biological Materials

7 months agoDiscover why ultra-low temperature freezers (-86°C) are vital for preserving cells, proteins, and vaccines. Learn the science behind ULT storage best practices.

Learn More

Upright vs. Chest ULT Freezers: How to Choose the Right Configuration for Your Lab

7 months agoCompare upright vs. chest ULT freezers for your lab: temperature stability, workflow efficiency, and cost analysis to protect sensitive samples.

Learn More

How ULT Freezers Prevent Catastrophic Loss of Microbiological Samples

7 months agoULT freezers safeguard microbiological samples with advanced temperature control, contamination prevention, and emergency backup systems to prevent catastrophic loss.

Learn More

Beyond the Spec Sheet: Matching Freeze Dryer Capabilities to Your Application's Critical Needs

7 months agoChoose the right freeze dryer for pharma, food, or biotech. Key specs like cold trap temp, vacuum, and cooling rate impact drying speed and product quality.

Learn More

How ULT Freezers Protect Scientific Discoveries in Genetics and Drug Development

7 months agoULT freezers safeguard genetic and pharmaceutical research by maintaining -80°C storage for DNA, proteins, and cell lines—preventing sample degradation and ensuring research validity.

Learn More

Preserving the Irreplaceable: How ULT Freezers Protect Critical Samples Across Industries

7 months agoULT freezers at -80°C protect biological samples, vaccines, and research materials from degradation, ensuring long-term viability across industries.

Learn More

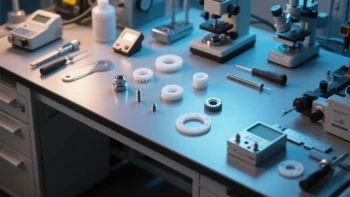

Polytetrafluoroethylene (PTFE): How low friction coefficient promotes industrial progress

8 months agoExplore the unique advantages of polytetrafluoroethylene (PTFE)'s low coefficient of friction and analyze how it promotes progress and innovation in industrial technology in terms of reducing wear and improving equipment efficiency.

Learn More