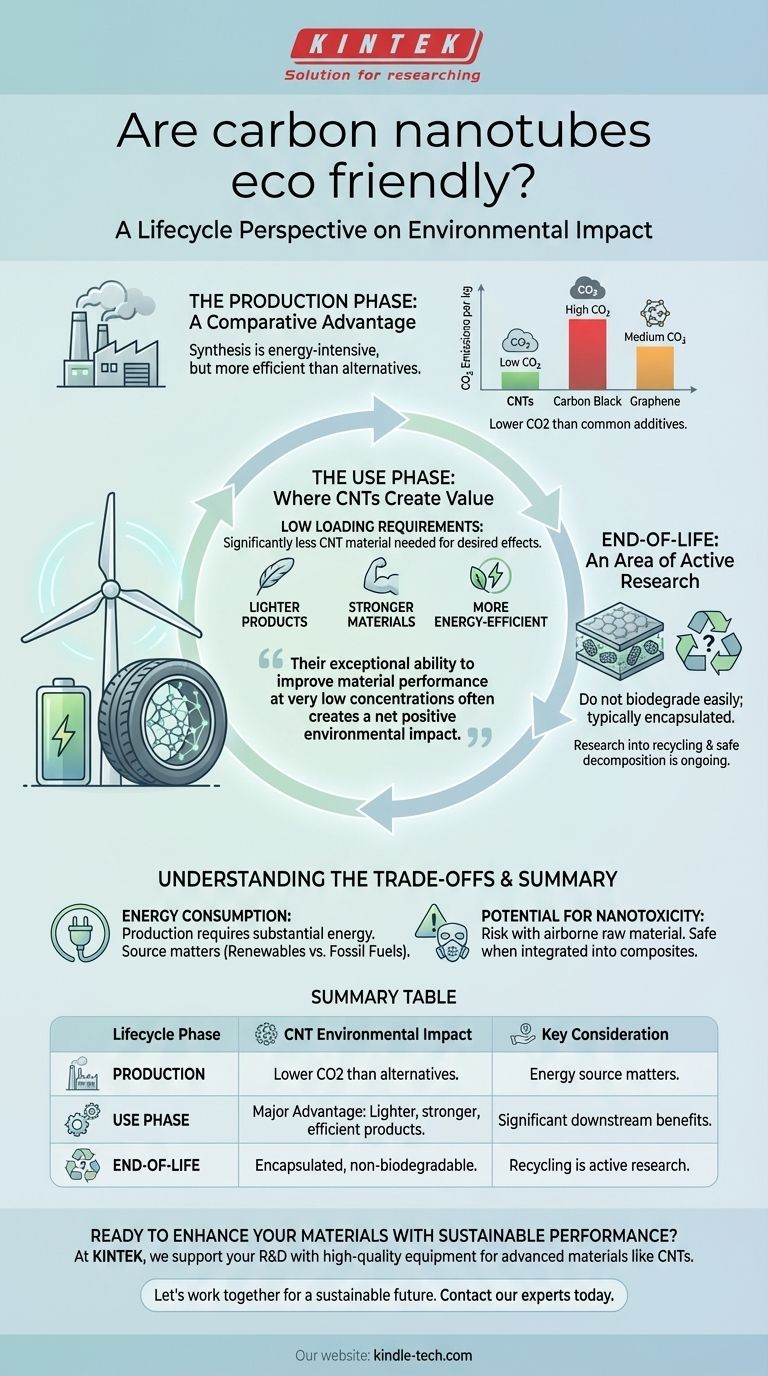

From a purely manufacturing standpoint, the environmental profile of carbon nanotubes (CNTs) is complex, but it shows a distinct advantage over common alternatives. Compared to materials like carbon black or many forms of graphene, the production of CNTs typically results in lower CO2 emissions per kilogram. The full story, however, extends far beyond the factory.

The true eco-friendliness of carbon nanotubes is not found in their production process alone, but in their entire lifecycle. Their exceptional ability to improve material performance at very low concentrations often creates a net positive environmental impact that far outweighs their initial manufacturing footprint.

A Lifecycle View of Environmental Impact

To accurately assess if a material is "eco-friendly," we must look beyond a single metric like manufacturing emissions. A full lifecycle assessment considers production, the performance during use, and what happens at the end of a product's life.

The Production Phase: A Comparative Advantage

The synthesis of carbon nanotubes is an energy-intensive process. However, when placed in context with competing materials, it is often the more efficient option.

The production of carbon black, a common additive, generates higher CO2 emissions. Similarly, many methods for producing graphene face significant challenges with energy efficiency, high water consumption, and the use of harsh chemicals.

The Use Phase: Where CNTs Create Value

This is where the environmental case for CNTs becomes compelling. Their extraordinary properties mean a very small amount can create a dramatic improvement in a final product.

This concept is known as loading requirements. Because you need significantly less CNT material compared to carbon black to achieve a desired effect (like conductivity or strength), the initial manufacturing impact is minimized on a per-product basis. This leads to lighter, more durable, and more energy-efficient products, from stronger wind turbine blades to longer-lasting batteries and more fuel-efficient tires.

End-of-Life: An Area of Active Research

The final stage of the lifecycle is the most significant area of uncertainty for CNTs. Their strong carbon-carbon bonds mean they do not biodegrade easily.

Currently, the primary end-of-life scenario is that CNTs remain safely encapsulated within the composite material they strengthen. Research into recycling and safe decomposition methods is ongoing, but this remains a critical consideration for new applications.

Understanding the Trade-offs

No material is perfect. Acknowledging the challenges associated with CNTs is crucial for making an informed decision.

Energy Consumption

While comparatively efficient, the production of high-quality CNTs still requires substantial energy input, typically involving high temperatures. The source of this energy—whether from renewables or fossil fuels—heavily influences the overall carbon footprint.

Potential for Nanotoxicity

A key concern is the potential health impact of raw, airborne CNTs, as some forms have properties similar to asbestos fibers. This is a serious consideration for those handling the raw material.

It is critical to note that once CNTs are integrated into a composite matrix (like plastic or epoxy), they are locked in place and do not pose this risk. Proper industrial hygiene and handling protocols are non-negotiable during manufacturing.

Making an Informed Material Choice

Your evaluation of carbon nanotubes should be guided by your primary goal for the end product.

- If your primary focus is reducing manufacturing CO2: CNTs often present a clear advantage over traditional additives like carbon black and many forms of graphene.

- If your primary focus is improving product lifecycle performance: The high efficiency of CNTs enables lighter, more durable, and more energy-efficient products, creating a powerful net environmental positive.

- If your primary focus is risk mitigation and end-of-life: The potential for toxicity during handling and the lack of biodegradability require careful management and consideration in your product design.

Ultimately, viewing carbon nanotubes through a full lifecycle lens reveals them as a powerful tool for achieving greater system-level sustainability.

Summary Table:

| Lifecycle Phase | CNT Environmental Impact | Key Consideration |

|---|---|---|

| Production | Lower CO2 emissions per kg than carbon black & many graphene forms. | Energy-intensive process; source of energy matters. |

| Use Phase | Major Advantage: Low loading requirements create lighter, stronger, more energy-efficient products. | Enables significant downstream environmental benefits. |

| End-of-Life | Do not biodegrade; typically remain encapsulated in composites. | Recycling and safe decomposition methods are areas of active research. |

Ready to enhance your materials with sustainable performance?

At KINTEK, we specialize in providing high-quality laboratory equipment and consumables to support your research and development with advanced materials like carbon nanotubes. Our products help you accurately test, analyze, and integrate CNTs to create stronger, lighter, and more efficient solutions.

Let's work together to build a more sustainable future. Contact our experts today to discuss how our solutions can meet your specific laboratory needs.

Visual Guide

Related Products

- Boron Nitride (BN) Ceramic Tube

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tubes

- Multi-zone Laboratory Tube Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Cold Trap Chiller Indirect Cold Trap Chiller

People Also Ask

- What is a ceramic tube? A Guide to Extreme Environment Performance

- What are ceramic tubes used for? Essential Components for Extreme Heat & Electrical Insulation

- What are the strengths of brazing? Achieve Strong, Clean, and Precise Metal Joining

- What are the disadvantages of brazing? Understanding the key limitations and trade-offs.

- What is the function of the ceramic tube in a DBD plasma jet? Enhancing Stability for Delicate Material Treatment