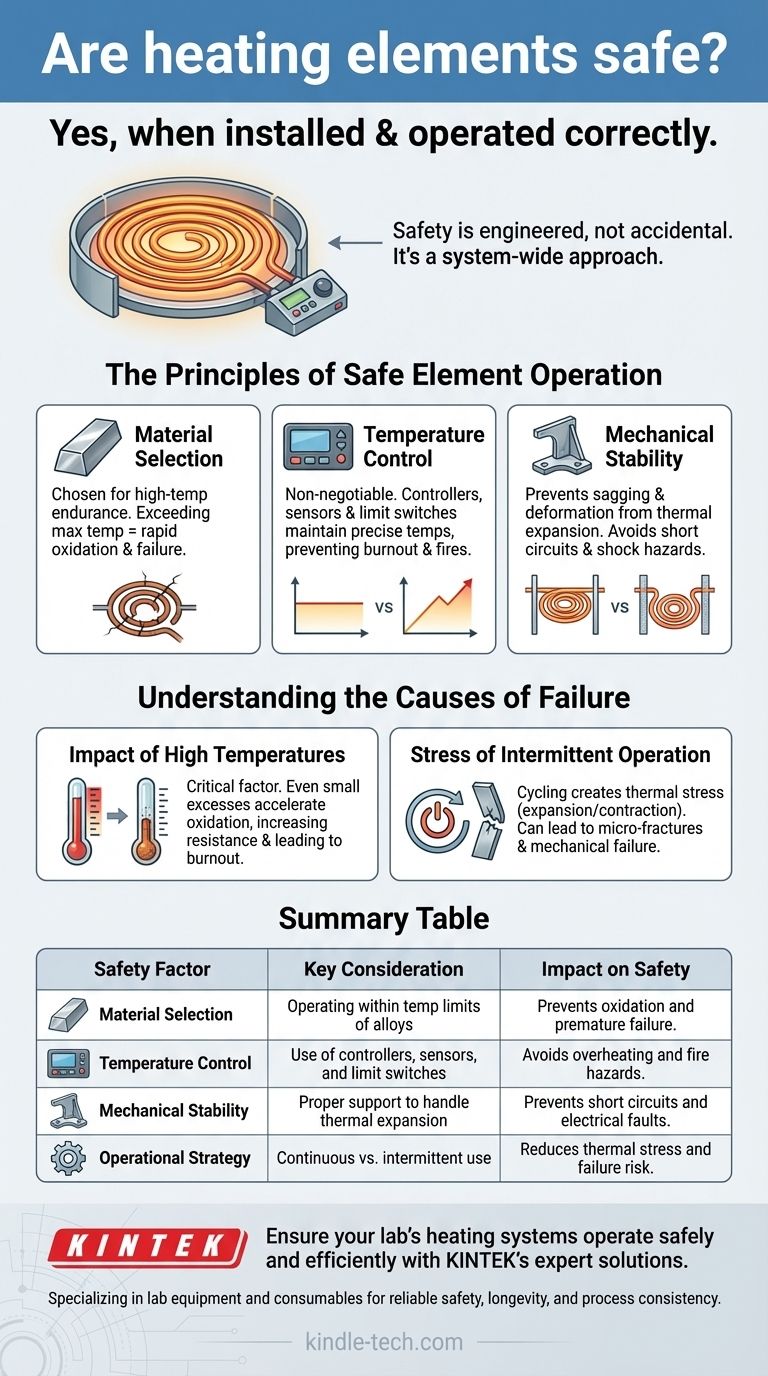

In short, yes. Modern electric heating elements are designed to be exceptionally safe when installed and operated correctly within their specified limits. Their safety is not an accident but the result of careful engineering, material science, and the implementation of proper control systems.

The safety and longevity of a heating element are not inherent properties but are determined by a system-wide approach. It depends critically on selecting the right element for the job, controlling its temperature, and ensuring its mechanical and electrical integrity throughout its operational life.

The Principles of Safe Element Operation

A heating element's core function is to convert electrical energy into heat. The primary risks—overheating, fire, and electrical shock—are managed by addressing a few key factors from design through to operation.

Material Selection Dictates Performance

The material an element is made from (such as a nickel-chromium or iron-chromium-aluminum alloy) is chosen for its ability to operate at high temperatures without rapid degradation.

Each material has a maximum operating temperature. Exceeding this temperature significantly accelerates oxidation, which weakens the element and leads to premature failure.

Temperature Control is Non-Negotiable

Safety is fundamentally about control. Uncontrolled heating elements will continue to get hotter until they burn out, potentially causing a fire.

Modern systems use controllers, sensors (like thermocouples), and limit switches to maintain a precise temperature. This not only ensures safety but also provides for a consistent process and extends the element's life.

Mechanical Stability Prevents Electrical Faults

Heating elements expand when hot and contract when cool. They also lose strength at very high temperatures.

Proper mechanical support is crucial to prevent the element from sagging or deforming. A deformed element can make contact with the furnace frame or another part of the element, causing an electrical short circuit that can damage the equipment and create a shock hazard.

Understanding the Causes of Failure

The factors that shorten an element's life are the same ones that can compromise its safety. Understanding them is key to reliable operation.

The Impact of High Temperatures

The single most critical factor affecting an element's lifespan is its operating temperature. Even a small increase above the recommended temperature can dramatically shorten its life.

This is because high temperatures accelerate the rate of oxidation, which degrades the element's material and increases its electrical resistance, eventually leading to a burnout.

The Stress of Intermittent Operation

While it may seem counterintuitive, running an element continuously at a stable temperature is often less stressful than cycling it on and off.

Each heating and cooling cycle creates thermal stress as the element expands and contracts. This repeated stress can lead to micro-fractures and eventual mechanical failure, much like bending a paperclip back and forth.

Making the Right Choice for Your Goal

Ensuring the safety and reliability of your heating system involves aligning your operational strategy with your primary objective.

- If your primary focus is maximum lifespan: Operate the element well below its maximum temperature rating and, where possible, favor longer periods of continuous operation over frequent on-off cycling.

- If your primary focus is process consistency: Implement a high-quality temperature control system with accurate sensors to maintain a stable and precise operating temperature.

- If your primary focus is safety above all: Ensure your system includes redundant over-temperature protection and that all elements are properly supported and regularly inspected for signs of degradation or deformation.

Ultimately, a heating element's safety is a direct reflection of the system in which it operates and the care with which it is maintained.

Summary Table:

| Safety Factor | Key Consideration | Impact on Safety |

|---|---|---|

| Material Selection | Operating within temperature limits of alloys (e.g., Ni-Cr) | Prevents oxidation and premature failure |

| Temperature Control | Use of controllers, sensors, and limit switches | Avoids overheating and fire hazards |

| Mechanical Stability | Proper support to handle thermal expansion | Prevents short circuits and electrical faults |

| Operational Strategy | Continuous vs. intermittent use | Reduces thermal stress and failure risk |

Ensure your lab’s heating systems operate safely and efficiently with KINTEK’s expert solutions.

We specialize in lab equipment and consumables, providing reliable heating elements and control systems tailored to your laboratory needs. From material selection to temperature management, our products are designed to maximize safety, longevity, and process consistency.

Contact us today to discuss how we can enhance your thermal processing safety and performance!

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- High Quality Alumina Ceramic Screw for Engineering Advanced Fine Ceramics with High Temperature Resistance and Insulation

People Also Ask

- What are silicon carbide heating elements used for? Reliable High-Temp Heating for Industrial Processes

- What factors affect the resistance of a heating element? Master the 4 Key Variables for Precise Thermal Design

- How can you tell if a heating element is bad? Diagnose with a Multimeter in 4 Steps

- Is tungsten a good heating element? Unlock Extreme Temperatures in Vacuum Environments

- How does an electric oven heating element work? The Science of Resistive Heating Explained

- How do resistive heating elements work? Unlock the Science of Efficient Heat Generation

- What is the temperature limit of silicon carbide? Maximize Performance from 1600°C to 2500°C

- What are the factors on which heat produced in a heating element depends? Master Joule's Law for Precise Control