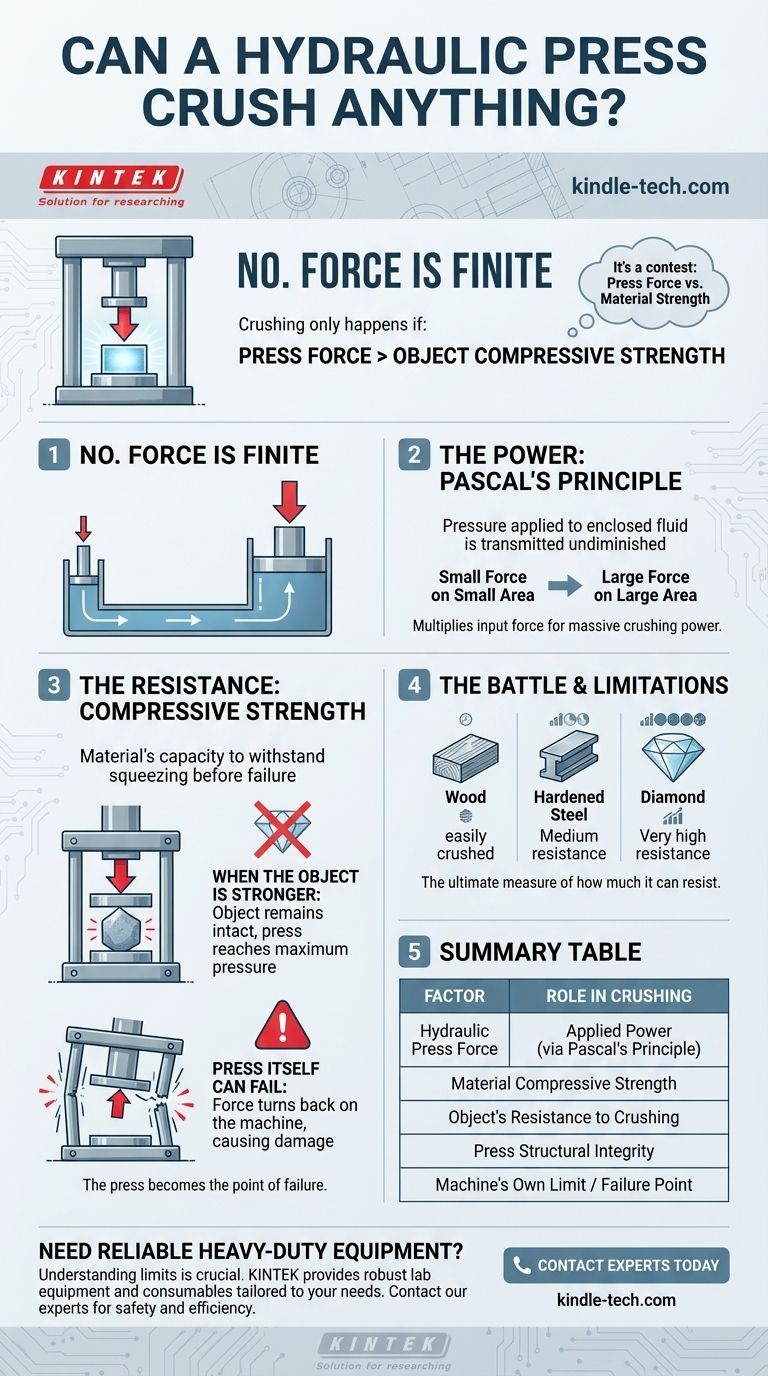

No, a hydraulic press cannot crush absolutely anything. While its power is immense and capable of crushing materials as strong as hardened steel, its force is ultimately finite. An object will only be crushed if the force exerted by the press is greater than the object's internal compressive strength.

The ability of a hydraulic press to crush an object is not a matter of absolute power, but a contest between two factors: the force generated by the press and the compressive strength of the material it is attempting to crush.

The Principle Behind the Power

A hydraulic press operates on a fundamental law of physics known as Pascal's Principle. Understanding this is the key to understanding its incredible force.

What is Pascal's Principle?

Pascal's Principle states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In simple terms, a small force applied to a small area in a hydraulic system generates a much larger force on a larger area.

How it Creates Force

A typical press uses a small piston (the plunger) and a large piston (the ram). When you apply a small amount of force to the plunger, it creates pressure in the hydraulic fluid.

This same pressure is then applied to the entire surface of the much larger ram, multiplying the initial force into a massive crushing power. This is how a small motor can generate hundreds of tons of force.

The Deciding Factor: Compressive Strength

The power of the press is only half of the equation. The other half is the object's ability to resist that power.

Defining Compressive Strength

Compressive strength is the capacity of a material to withstand loads that tend to decrease its size. It is the ultimate measure of how much squeezing or squashing a material can resist before it fails or deforms permanently.

A Tale of Two Materials

A block of wood has a relatively low compressive strength and is easily crushed. A block of high-grade steel has an extremely high compressive strength, requiring immense force.

Materials like diamonds or advanced ceramics have compressive strengths that are orders of magnitude higher than most metals, making them exceptionally difficult to crush.

Understanding the Trade-offs and Limitations

A hydraulic press is a powerful tool, but its limits are defined by physics and its own construction. It is not an unstoppable force.

When the Object is Stronger

If an object's compressive strength exceeds the maximum force the press can generate, the object will not be crushed. The press will reach its maximum pressure, and the system will simply stop, with the object remaining intact.

The Press Itself Can Fail

A hydraulic press is also an object made of materials with their own compressive and tensile strengths.

If you attempt to crush an object that is stronger than the press's own frame or ram, the force will be turned back on the machine itself. This can cause the frame to bend, the seals to burst, or the ram cylinder to crack. The press becomes the point of failure.

The Theoretical "Uncrushable" Object

Theoretically, an object made of a material like a large, flawless diamond or certain advanced nanostructures would have a compressive strength so high that it would exceed the capabilities of even the most powerful hydraulic presses ever constructed.

Making the Right Choice for Your Understanding

Your understanding of a hydraulic press depends on which side of the force equation you are focused on.

- If your primary focus is its immense power: Remember that its strength comes from Pascal's Principle, which multiplies a small initial force into a massive output.

- If your primary focus is its limitations: Recognize that its ability to crush anything is limited by the compressive strength of the target material and the structural integrity of the press itself.

Ultimately, the operation of a hydraulic press is a perfect demonstration of the balance between applied force and a material's inherent resistance.

Summary Table:

| Factor | Description | Role in Crushing |

|---|---|---|

| Hydraulic Press Force | Force generated via Pascal's Principle, multiplying input force. | The "applied power" trying to crush the object. |

| Material Compressive Strength | The maximum pressure a material can withstand before deforming. | The object's "resistance" to being crushed. |

| Press Structural Integrity | The strength of the press's own frame, ram, and seals. | The machine's own limit; failure point if object is too strong. |

Need a reliable partner for your lab's heavy-duty equipment?

Understanding the precise limits of machinery like hydraulic presses is crucial for safe and effective operations. At KINTEK, we specialize in providing robust lab equipment and consumables tailored to your specific research and industrial needs. Whether you're testing material strength or require durable machinery that performs to its specifications, we have the expertise and products to support your work.

Contact our experts today to find the right equipment that matches your application's demands and ensures safety and efficiency in your laboratory.

Visual Guide

Related Products

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What role does a laboratory hydraulic press play in all-solid-state battery fabrication? Enhancing Ion Conductivity

- How is a laboratory hydraulic press used for LLZTO pellets? Achieve 93% Density in Solid-State Battery Research

- How does a hydraulic hot press machine work? Unlock Precision in Material Bonding and Forming

- What is the purpose of using a laboratory hydraulic press for nanocomposites? Ensure Precise Material Characterization

- What is the purpose of applying high pressure in dry cathode preparation? Achieve Peak Solid-State Battery Density