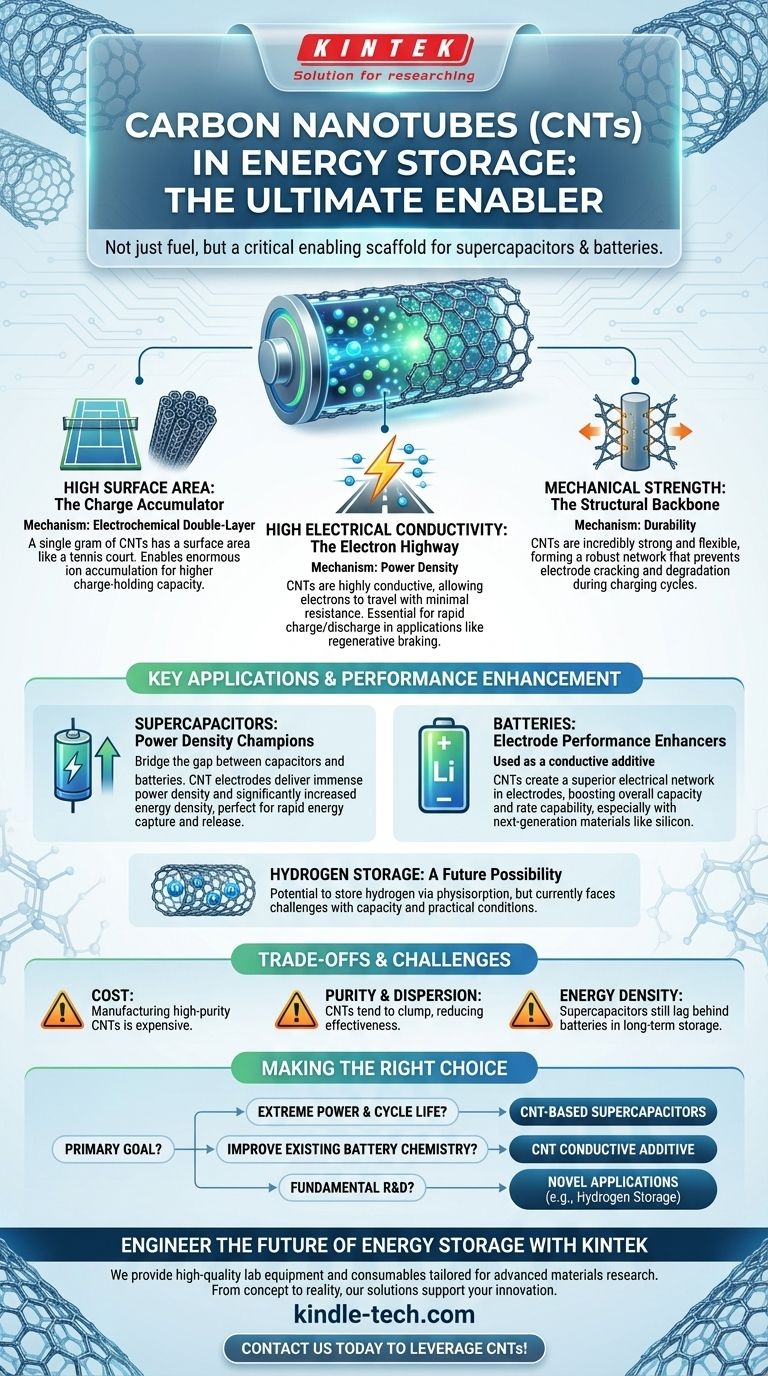

Yes, carbon nanotubes can store energy, but they primarily function as a critical enabling material within energy storage devices rather than as a standalone fuel source. Their extraordinary physical properties—specifically their immense surface area, high electrical conductivity, and remarkable strength—make them exceptional candidates for enhancing the performance of supercapacitors and batteries.

The core value of carbon nanotubes (CNTs) in energy storage lies not in storing energy themselves, but in creating high-performance structures within devices like supercapacitors and batteries. They act as a superior scaffold that dramatically improves charge-holding capacity, charge/discharge speed, and device longevity.

How CNTs Function in Energy Storage

The effectiveness of carbon nanotubes stems from a unique combination of three physical properties. Understanding these is key to seeing their value.

The Principle of High Surface Area

Energy storage in devices like supercapacitors is a surface phenomenon. The device stores energy by accumulating ions on the surface of its electrodes, a mechanism known as the electrochemical double-layer.

A single gram of CNTs can have a surface area similar to a tennis court. This vast area allows for an enormous number of ions to accumulate, directly translating to a higher capacity for storing charge compared to traditional materials like activated carbon.

The Role of Electrical Conductivity

The speed at which an energy storage device can be charged or discharged depends on how quickly electrons can move through its electrodes. This is known as its power density.

Carbon nanotubes are highly conductive, providing an efficient "highway" for electrons to travel with very little resistance. This property is essential for applications requiring rapid bursts of power, such as regenerative braking in electric vehicles or stabilizing an electrical grid.

The Advantage of Mechanical Strength

In batteries, electrode materials like silicon can swell and shrink dramatically during charge and discharge cycles. This physical stress causes the material to crack and degrade over time, reducing the battery's lifespan.

CNTs are incredibly strong and flexible. When integrated into a battery electrode, they form a robust, conductive network that holds the active materials together, accommodating the volume changes and preventing mechanical failure.

Key Applications in Energy Devices

CNTs are not a one-size-fits-all solution. Their properties make them ideal for specific roles within different types of energy storage systems.

Supercapacitors: Power Density Champions

Supercapacitors bridge the gap between traditional capacitors and batteries. They can charge and discharge almost instantly (high power density) but historically stored less energy (lower energy density).

By using CNTs as the electrode material, we can build supercapacitors that not only deliver immense power but also have a significantly increased energy density. This makes them ideal for applications that need to capture and release energy very quickly.

Batteries: Enhancing Electrode Performance

In lithium-ion batteries, CNTs are most commonly used as a conductive additive in the electrodes, typically comprising just a small percentage of the total weight.

Their primary role is to create a superior electrical network throughout the electrode, ensuring all active material particles can participate in the electrochemical reaction. This boosts the battery's overall capacity and rate capability, especially when using next-generation anode materials like silicon.

Hydrogen Storage: A Future Possibility

Researchers have explored using the hollow cores and exterior surfaces of CNTs to store hydrogen gas through a process called physisorption.

While theoretically promising due to their low weight and high surface area, this application remains largely in the research phase. Current challenges include achieving sufficient storage capacity at room temperature and practical pressures.

Understanding the Trade-offs and Challenges

Despite their immense potential, deploying CNTs is not without significant engineering and economic hurdles.

Cost of Production

Manufacturing high-purity, structurally consistent carbon nanotubes remains an expensive process compared to conventional materials. This cost factor is a major barrier to their widespread adoption in mass-market applications.

Purity and Dispersion Issues

Due to strong intermolecular forces, CNTs have a natural tendency to clump together, or agglomerate. This bundling severely reduces their effective surface area and negates many of their benefits.

Achieving a uniform dispersion of nanotubes within an electrode matrix is a complex and critical manufacturing challenge that directly impacts device performance and consistency.

Energy Density Limitations

For all their advantages in power density, CNT-based supercapacitors still cannot match the energy density of modern batteries. They can deliver power faster, but a battery of the same weight can store and deliver that power for a much longer time.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary goal of your energy storage system.

- If your primary focus is extreme power density and cycle life: CNT-based supercapacitors are the superior choice for applications like grid frequency regulation, regenerative braking, or industrial machinery.

- If your primary focus is improving the performance of existing battery chemistry: Using CNTs as a conductive additive in battery electrodes can significantly enhance rate capability and extend cycle life, especially for high-capacity materials.

- If your primary focus is fundamental research and development: Exploring CNTs for novel applications like hydrogen storage or flexible energy devices remains a promising frontier.

Carbon nanotubes represent a powerful tool for engineering the next generation of energy storage, enabling performance characteristics that are simply unattainable with conventional materials.

Summary Table:

| Property | Role in Energy Storage | Key Benefit |

|---|---|---|

| High Surface Area | Electrode Scaffold | Increases charge-holding capacity (energy density) |

| High Electrical Conductivity | Electron Highway | Enables rapid charge/discharge (power density) |

| Exceptional Mechanical Strength | Structural Support | Enhances electrode durability and cycle life |

Ready to engineer the next generation of energy storage?

Carbon nanotubes are not just a material; they are a pathway to superior performance in supercapacitors and batteries. At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored for advanced materials research and development. Whether you're developing high-power supercapacitors or enhancing battery electrodes, our solutions support your innovation from concept to reality.

Contact us today to discuss how we can help you leverage the unique properties of carbon nanotubes for your specific energy storage challenges. Get in touch with our experts and let's power up your research together!

Visual Guide

Related Products

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- High Purity Zinc Foil for Battery Lab Applications

- Electrode Polishing Material for Electrochemical Experiments

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Custom PTFE Teflon Parts Manufacturer for PTFE Containers

People Also Ask

- Why is an argon-filled glove box essential for Li-CuMH solid-state batteries? Ensure Component Stability

- What is the function of CR2032 coin cell cases in the evaluation of LSLBO electrolyte? Optimize Battery Test Results

- What is the purpose of using a precision laboratory oven for solid-state battery testing? Ensure High-Temp Stability

- Why use an Ar/H2 mixture for VPO4 intermediate preparation? Mastering Reducing Environments for Battery Synthesis

- Why are Al-doped LLZO samples subjected to post-treatment? Restoring Purity for Solid Electrolyte Performance

- What are carbon cloths used for? Conquer Static Dust on Electronics & Screens

- What is the significance of precise temperature control in melt infiltration? Achieve High-Performance Li-Alloy Electrodes

- What function does a CR2032 button cell case serve in testing solid-state sodium batteries? Optimize Your Lab Results